News

Find out the latest Kardex news, developments, reports, and company information. Browse the Kardex News Center to stay up to speed on all public announcements. If you can’t find what you’re looking for, contact us directly, and we’ll be happy to help you.

No Items Found!

-

8.04.2024 Company News

Kardex Mlog secures continuous replenishment in production

Kardex Mlog has built two structurally identical, automated buffer storage plants for the BASF chemicals company. The new facility includes warehouse management and conveying technology to connect...

-

5.04.2024 Company News

Kardex Mlog builds a 42-meter-tall high-bay warehouse for RHW Logistik

RHW Logistik GmbH commissioned Kardex Mlog to construct a new logistics center at its Krefeld location. The new facility has a surface area of 9,850 square meters, built on a site of 21,100 square...

-

27.03.2024 Company News

Neuberger Transforms Intralogistics with Innovative Kardex Robotic Technology

Neuberger, a company focused on enhancing building efficiency and comfort, will install Kardex`s newest automated SMD storage solution to optimize intralogistics processes within their warehouse...

-

11.03.2024 Company News

Kardex Remstar: Kardex Compact Buffer renamed to Kardex Miniload-in-a-Box

-

7.03.2024 Ad Hoc

Kardex Holding AG: Financial Results 2023

-

26.02.2024 Company News

LogiMAT 2024: New hardware and software for efficiency and ergonomics

This year’s LogiMat takes place in Stuttgart from March 19 to 21. At the Kardex stand (Hall 1, Stand H49), the company will be presenting the latest developments towards greater efficiency in...

-

25.01.2024 Company News

Kardex and Addverb start partnership in the area of intralogistics software

Zurich, 16 January 2024– Kardex has agreed a strategic partnership with Addverb in the area of intralogistics software. Addverb is a leading global robotics and warehouse automation company based in...

-

19.01.2024 Company News

Kardex Mlog: Winnie Ahrens to head New Business

Winnie Ahrens (50) heads the New Business sector at Kardex Mlog. “I believe we have growth opportunities through geographical expansion on the one hand and through the strategic expansion of...

-

16.01.2024 Company News

EagleBurgmann modernizes its logistics at the Eurasburg site with the AutoStore solution from Kardex

The EagleBurgmann Group, a leading international manufacturer of industrial sealing technology, is preparing for the future. With the implementation of Kardex AutoStore, the production site in...

-

15.01.2024 Company News

Thorlabs to enhance distribution capabilities with AutoStore empowered by Kardex

The robotic cube storage system, AutoStore, will enable Thorlabs to accommodate future growth by maximizing storage space within their new distribution center.

-

9.01.2024 Company News

Kardex Mlog: Sven Pitz to head Refurbishment business sector

Sven Pitz (48) is the new head of the Refurbishment business sector at Kardex Mlog. Sven Pitz is the new Manager Sales New Business Refurbishment at Kardex Mlog and thus assumes leadership of...

-

13.12.2023 Company News

VHIT invests in AutoStore solution to automate spare parts logistics in Italy

In October 2023, Kardex handed over a turnkey and future-proof AutoStore solution to Automotive supplier VHIT. Perfectly adapted to the spatial conditions on site, the automated storage and...

-

11.12.2023 Company News

Setting New Warehouse Safety Standards: How Rubix Leveraged Kardex Solutions for Hazardous Storage

Rubix, a renowned global distributor of industrial products, teamed up with Kardex, a global leader in smart intralogistics solutions, to develop a cutting-edge hazardous materials storage solution....

-

1.11.2023 Company News

Ergonomics and Safety at the Forefront: Kardex Outlines the Future of Work in Intralogistics

Amid a world of talent shortages, lingering effects of the pandemic, and other struggles, Kardex offers innovative, safe and more ergonomic intralogistics solutions for future growth.

-

31.10.2023 Company News

Emil Frey Logistik is implementing two AutoStore solutions with Kardex to optimize its spare parts business

Emil Frey Logistik has implemented a dedicated AutoStore system in Kassel and Lehrte near Hanover to ensure the more efficient handling of spare parts. Emil Frey Logistik approached the...

-

16.10.2023 Company News

High-bay warehouse: Kardex Mlog building sustainably for Weleda

Weleda AG commissioned Kardex Mlog to supply six automated stacker cranes for its high-bay warehouse and shipping buffer at its new logistics campus at the Gügling business park in Schwäbisch Gmünd....

-

5.10.2023 Company News

ATS Group doubles warehouse performance with the Kardex Compact Buffer

ATS Group has elevated its warehouse operations to new heights by implementing the cutting-edge Vertical Buffer Module Kardex Compact Buffer (VBM) technology. This innovative solution has...

-

2.08.2023 Company News

Warehouse automation: Kardex Mlog building for reuter.de

The Mönchengladbach-based, family-owned company, reuter.de, one of Germany’s largest specialist and online retailers for bathrooms and lighting, commissioned Kardex Mlog with the construction of its...

-

31.07.2023 Company News

Dan Cake Polonia: Fast logistics for connoisseurs

Acting as general contractor for Dan Cake Polonia, Kardex Mlog constructed a high-performance, 3-aisle, high-bay warehouse with extensive conveying and control technology to ensure secure processes....

-

27.07.2023 Ad Hoc

Kardex Holding AG: Half-Year Results 2023

-

24.07.2023 Company News

Böllhoff Produktion GmbH optimizes assembly processes with fully automated Kardex solution

The Böllhoff Group sets new standards for efficient intralogistics processes at its production site in Bielefeld, Germany. By implementing a fully automated, space-saving as well as transparent...

-

7.06.2023 Company News

Playmobil optimizes spare parts logistics with innovative AutoStore solution

Everyone knows Playmobil and their famous toys. Millions of small, colorful Playmobil figures find their way into children's homes every year. In the last 50 years, countless parts and bundles have...

-

17.05.2023 Company News

Kardex doubles efficiency with flexible automated solutions tailored for third-party logistics

The Nordics’ leading third-party logistics (3PL) provider, Nowaste Logistics, with a focus on implementing high-quality and innovative automation solutions, commissioned Kardex to create a...

-

3.05.2023 Company News

MAHLE Aftermarket automates second Distribution Center with AutoStore empowered by Kardex

In Fall 2021, MAHLE Aftermarket commissioned Kardex with the planning and implementation of a highly efficient AutoStore solution for their Distribution Center in the US (Olive Branch, MS), which...

-

3.05.2023

High-bay warehouse: DACHSER takes the automation highway

-

3.05.2023 Company News

Balluff optimizes production supply in Hungary with AutoStore empowered by Kardex

In May 2023, Kardex will hand over a turnkey and future-proof AutoStore system to sensor specialist Balluff. Perfectly adapted to local conditions, the high-performance small parts warehouse will...

-

25.04.2023 Ad Hoc

Jens Hardenacke appointed new CEO of Kardex Holding AG

-

20.04.2023 Company News

Kardex Holding AG: Annual General Meeting 2023

The issuer is solely responsible for the content of this announcement.

-

13.04.2023 Company News

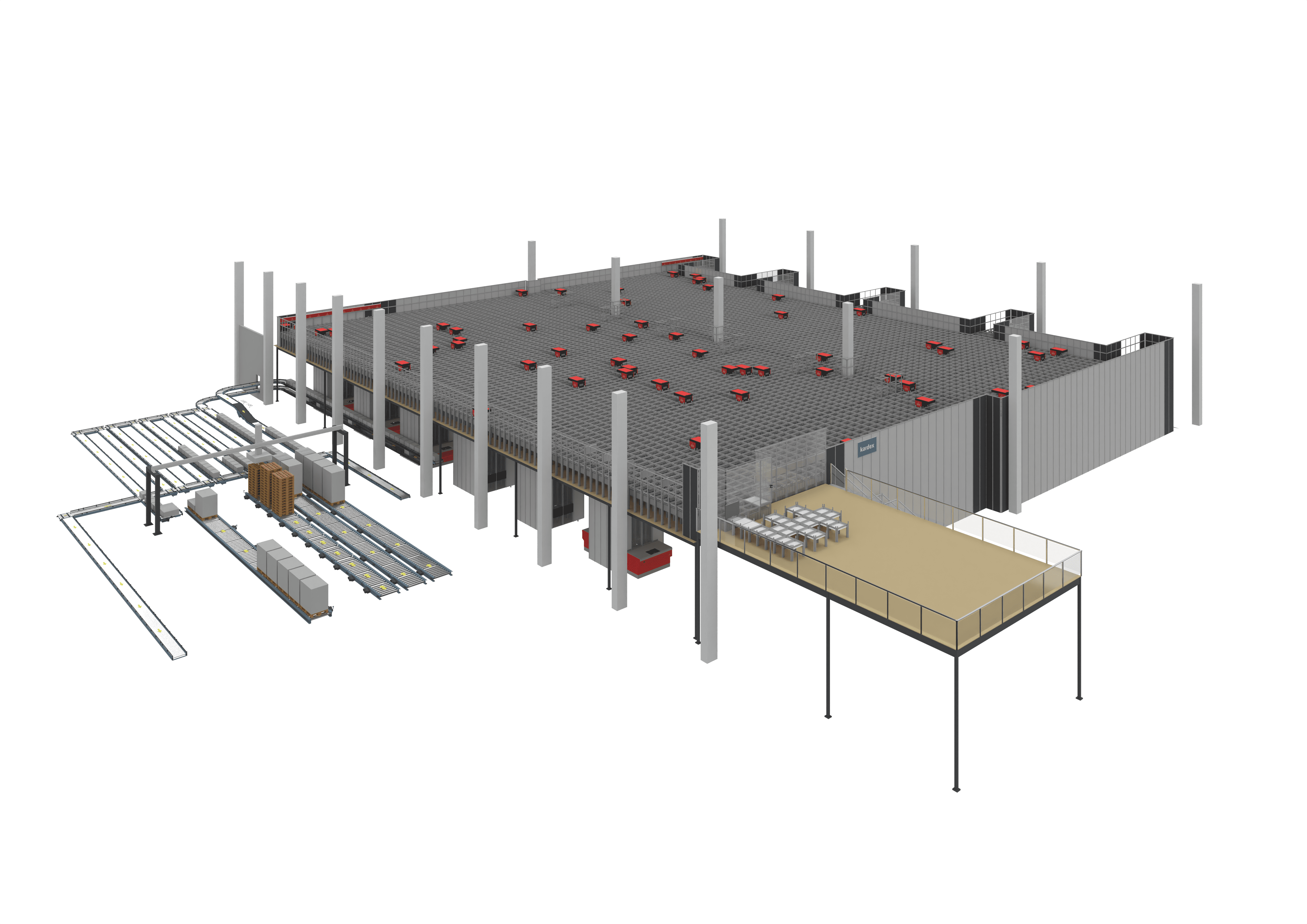

Construction materials handling automated with AutoStore empowered by Kardex at SABAG in Switzerland

To optimize small parts logistics, Kardex is implementing a highly efficient AutoStore solution for SABAG Luzern AG at their headquarters in Rothenburg (Switzerland). In the future, the AutoStore...

-

13.04.2023 Company News

Faster logistics at apetito

The catering and food specialist apetito commissioned Kardex Mlog with the refurbishment of its central refrigerated warehouse at its German production and logistics site in Rheine in North...

-

3.04.2023 Company News

Electronics wholesaler Sonepar equips new logistics center with AutoStore solution from Kardex

To ensure resilient, future-proof logistics and optimize the service level of customer deliveries in the greater Berlin area, Sonepar is commissioning a new logistics center in Werder near Berlin....

-

13.03.2023 Company News

Kardex introduces a new way of picking at LogiMAT 2023

Neuburg, Germany, March 06, 2023 - Kardex, a world-leading manufacturer of automated storage and retrieval systems (ASRS), presents a new and innovative way of picking at LogiMAT 2023. Showcasing its...

-

8.03.2023 Company News

MS Direct and Kardex implement innovative 3PL e-commerce fulfillment solution based on AutoStore

In the fast-moving e-commerce business, maximum availability of goods and minimum throughput times are important success factors. With a highly efficient AutoStore solution empowered by Kardex, the...

-

2.03.2023 Ad Hoc

Kardex Holding AG: Financial Results 2022

-

27.02.2023 Company News

anyseals chooses AutoStore empowered by Kardex to optimize their warehouse in Brecksville, Ohio

For their main U.S. facility in Brecksville, the wholesale sealing supplier was looking for a space-efficient and flexible solution that would increase efficiency in small parts handling and handle...

-

22.02.2023 Company News

GRASS Logistics Center: Best ideas for greenfield sites

Kardex Mlog was commissioned as general contractor by the GRASS Group, a specialist systems supplier to the furniture industry. The task was to build a highly automated high-bay warehouse with...

-

1.02.2023 Company News

Kardex Mlog honored as volunteer-friendly employer

On January 12, in the course of an official ceremony in Untergruppenbach, near the city of Heilbronn, Thomas Strobl, Interior Minister of Baden-Württemberg, honored Kardex Mlog as a...

-

23.01.2023 Company News

Kardex Reveals Warehouse Trends for 2023

As the intralogistics market continues to adapt to the world and economic conditions, the Kardex Trend Radar shows emerging trends for 2023.

-

18.01.2023 Company News

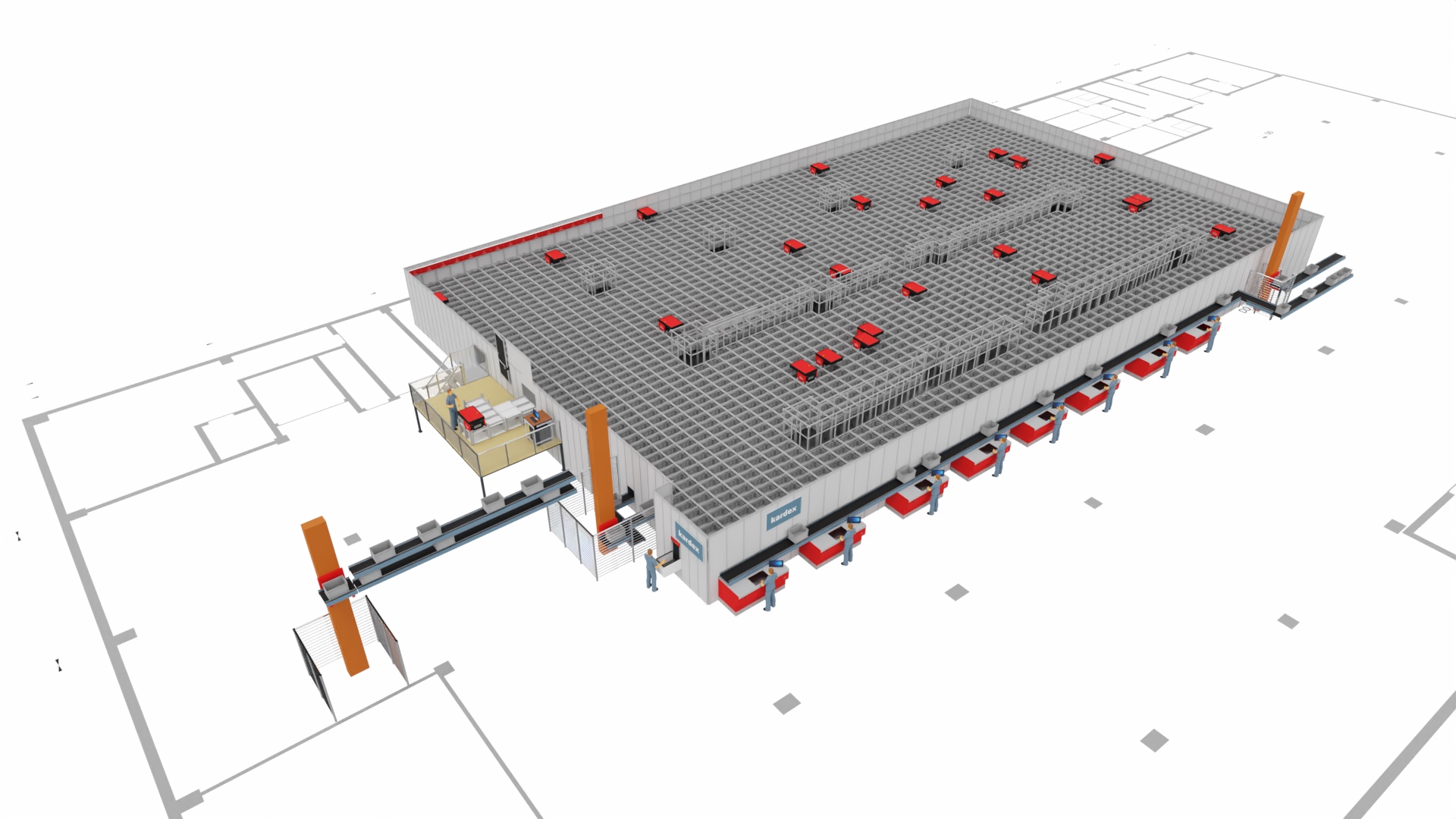

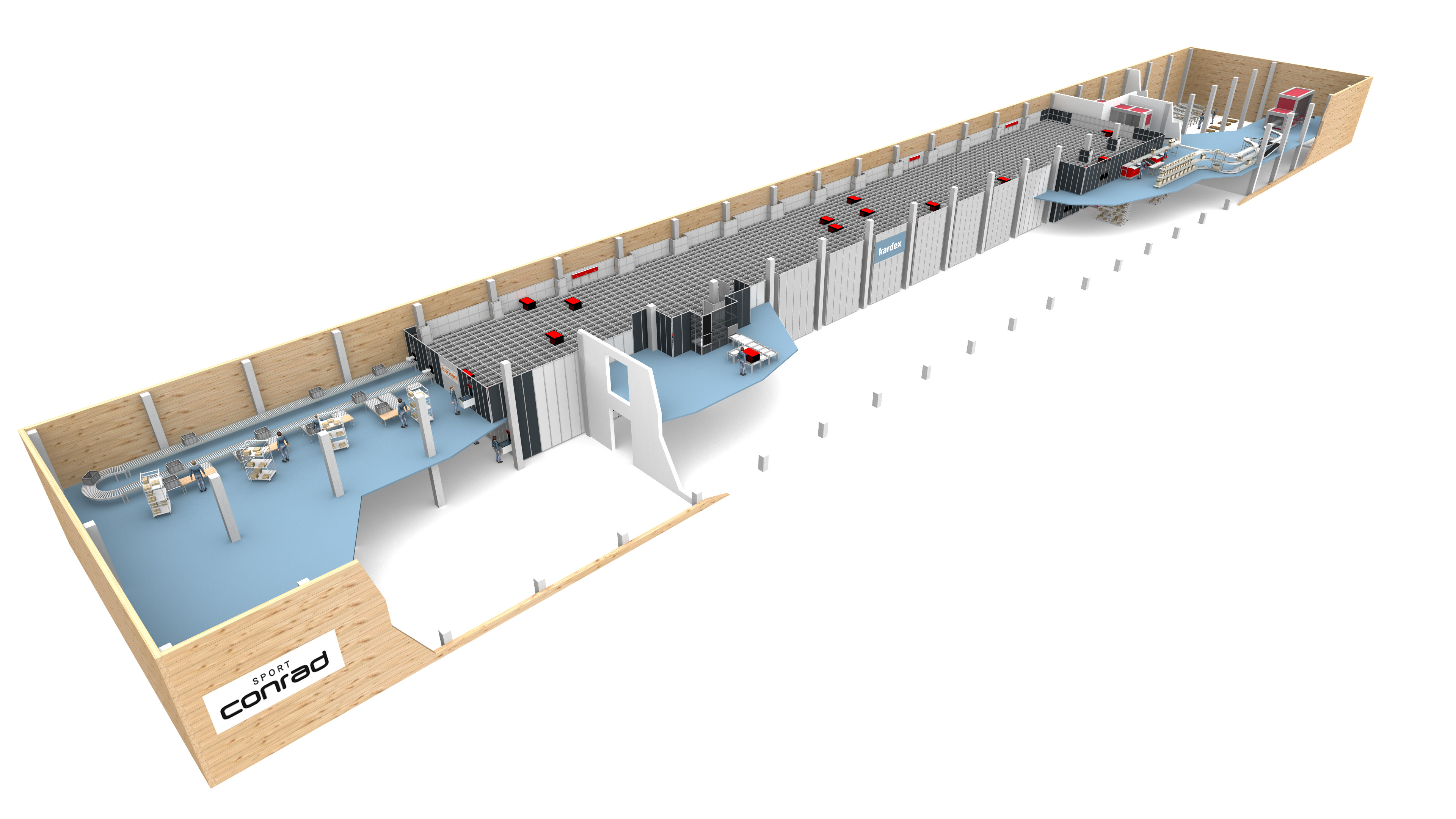

Sport Conrad increases efficiency in order fulfillment with sustainable AutoStore solution from Kardex

At Sport Conrad, located in the region of the Bavarian Alps, an automated storage and retrieval system will reliably handle steadily growing order volumes in the future. Optimally adapted to the...

-

15.12.2022 Company News

Double-deep with no wasted space: Berner optimizes storage

-

15.12.2022 Company News

Kardex expands AutoStore business to Asia Pacific

-

14.12.2022 Company News

Kardex Introduces a New Way of Picking at Promat 2023

Kardex, a world leading manufacturer of automated storage and retrieval systems (ASRS), is presenting a new and innovative way of picking at Promat 2023. Showcasing its latest developments in natural...

-

9.12.2022 Company News

Intralogistics: Kardex Mlog opts for experience in BeNeLux

-

25.11.2022 Ad Hoc

Kardex Holding AG: Jens Fankhänel will leave Kardex

-

18.11.2022 Ad Hoc

Kardex Holding AG: Kardex adjusts margin target for 2022

-

7.11.2022 Company News

Kardex Mlog Refurbishes REYHER’S High-Bay Warehouse

-

24.10.2022 Company News

The new Kardex Compact Buffer utilizes warehouse space from top to bottom and from side to side for long-term partner SHAKE-HAND

Five years ago, SHAKE-HAND implemented two Kardex Compact Buffers for efficient and accurate order picking of smaller materials at its facility in Belgium. Based on this success, the company knew...

-

10.10.2022 Company News

High-bay warehouse for Brauns-Heitmann: Optimizing the available space

-

7.10.2022 Company News

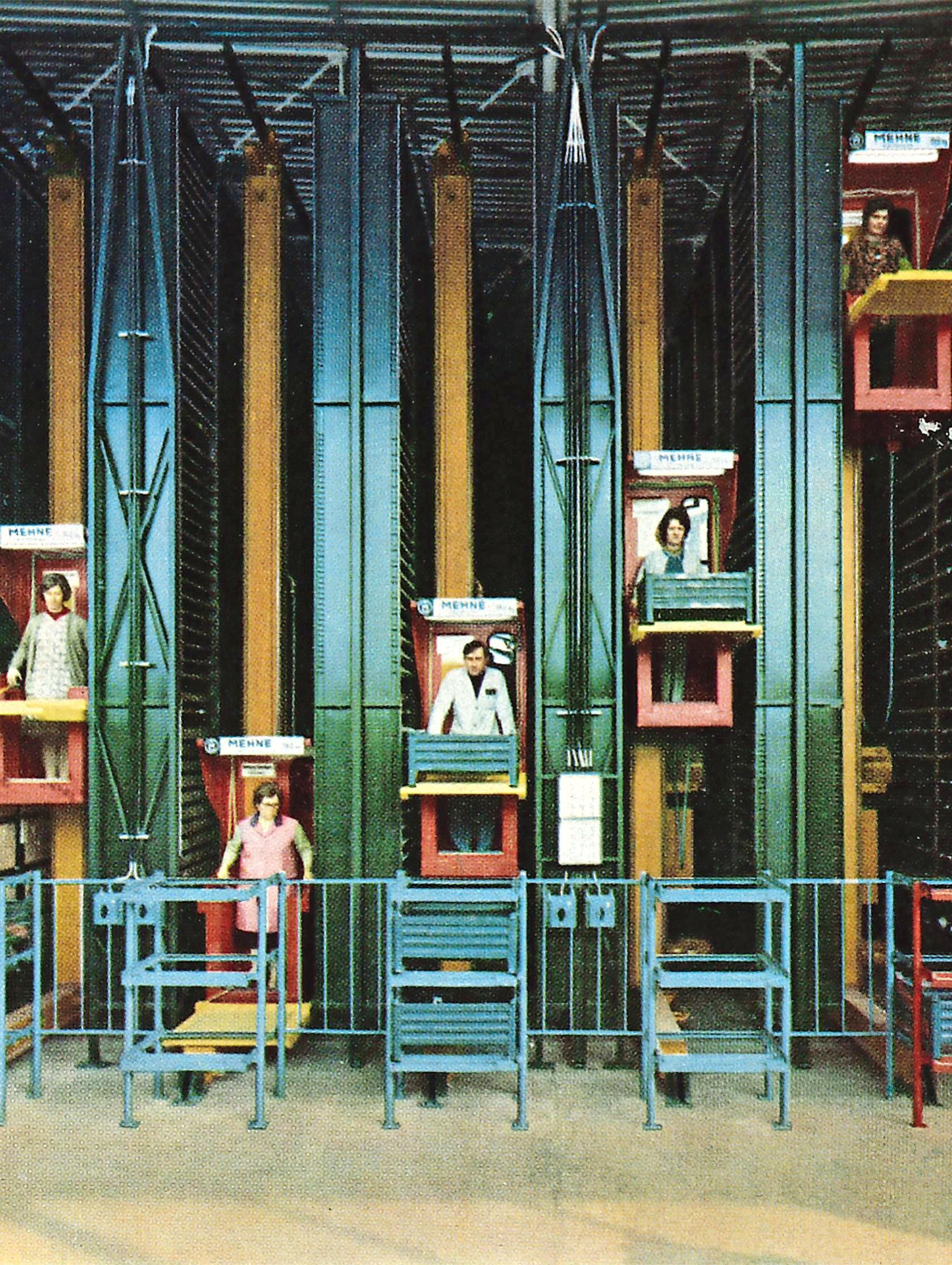

Intralogistics: Kardex Polska capitalizing on 75 years of experience

-

23.09.2022 Company News

Cutter & Buck automates Fulfillment Center in Washington with AutoStore empowered by Kardex

-

20.09.2022 Company News

Kardex Mlog: A pioneer reaches 100

-

18.08.2022 Company News

Electronics wholesaler Sonepar expands AutoStore facility with Robotics Pick and Pack solution from Kardex

Sonepar in Switzerland takes efficient logistics to the next level by investing in a robotic picking system. This makes them pioneers within the global Sonepar group. In the future, a Robotics Pick...

-

5.08.2022 Company News

Kardex optimizes Hitachi Energy’s high-voltage service warehouse in Zurich with AutoStore

For the reorganization of the spare parts business at the Dietlikon site in the Swiss canton of Zurich, Hitachi Energy was looking for an innovative, sustainable, and exceptionally flexible solution....

-

28.07.2022 Ad Hoc

Kardex Holding AG: Half Year 2022

-

19.05.2022 Company News

Kardex implements the world's first large AutoStore system with R5+ robots

In April 2022 the German online retailer Arbeitsschutz-Express has put a future-proof and highly efficient AutoStore solution into operation. The tailor-made solution was planned and implemented by...

-

10.05.2022 Company News

SkalHuset.se automates its new warehouse with an AutoStore solution from Kardex

As order volume increases, maintaining tight delivery times becomes challenging - putting pressure on the existing order picking, consolidation and packing processes. To keep pace with their rapid...

-

21.04.2022 Ad Hoc

Kardex Holding AG: Annual General Meeting 2022

-

21.04.2022 Company News

Kardex Mlog constructs additional high-bay warehouse for Eisbär Eis

-

8.03.2022 Company News

Raw material supply secured at Bridgestone

Neuenstadt, March 8, 2022 – Bridgestone, the world’s largest tire maker, has significantly increased its automatization of warehouse and distribution process at its production plant in Poznan,...

-

3.03.2022 Ad Hoc

Kardex Holding AG: Financial Year 2021

-

24.02.2022 Company News

BIKE24 automates its new logistics center with an AutoStore solution from Kardex

-

22.02.2022 Company News

Kardex Mlog Converts TME Facility During Ongoing Operations

Kardex Mlog / Electronic Components

-

20.01.2022 Company News

MAHLE Aftermarket automates DC in North America with AutoStore system from Kardex

New construction / Automation

-

13.01.2022 Company News

Südwestdeutsche Salzwerke selects Kardex to refurbish facilities

Kardex Mlog / Food

-

10.01.2022 Company News

Kardex Mlog installs a fully automated pallet transport between warehouses

Extension / Conveying Technology