If you scroll through LinkedIn for five minutes, you might think every warehouse is already humming along with robots, ASRS, and perfectly integrated systems.

The reality is very different.

A recent Kardex research study on integrated warehouse systems shows that most operations are still manual or only partially automated, and fully integrated environments are the exception, not the rule. At the same time, leaders overwhelmingly agree that integration is essential to getting real value from automation.

That tension is exactly what makes these statistics so important for 2026 planning.

About the Integrated Warehouse Systems Survey

The statistics in this article come from the Integrated Warehouse Systems Survey, a research project conducted by Kardex in partnership with Modern Materials Handling and Peerless Research Group.

The survey collected 127 responses from warehouse and DC leaders across a range of company sizes, industries, and roles, including company management, operations, engineering, and IT.

Roughly half of respondents work in manufacturing, with the remainder spread across wholesale, transportation and warehousing services, 3PLs, consulting, and retail. Facility sizes range from under 50,000 square feet to more than 250,000 square feet, giving a broad view of how integrated warehouse systems are being approached in both small and large operations.

Below are the most important numbers from the report, what they actually mean in practice, and how you can use them to shape your own roadmap.

How to Use These Stats

These numbers are useful on their own, but they are much more powerful if you treat them like a mirror.

As you read, ask yourself:

- Where are we on this spectrum today?

- Where do we want to be in two to three years?

- What is one concrete change we could make in the next 12 months to move closer?

You do not need to fix everything at once. The goal is to turn big industry trends into a few specific, realistic next steps for your operation.

Integrated Warehouse Systems Statistics

Before we get into the numbers, it helps to ground these terms in reality. When we talk about “manual,” “partially integrated,” or “fully integrated” warehouses, we are describing patterns, not strict categories.

No two facilities look exactly alike.

That said, there are some common scenarios that come up again and again. Here are a few examples of what each type of operation might look like on the floor and the kinds of technologies you might see in play.

At the end of the day, the best indicator is how manual you feel your processes are.

|

Warehouse type |

What it might look like day to day |

Example technologies you might see |

|

Manual warehouse |

Orders are released from a basic system, spreadsheet, or even just printed emails. Pickers push carts down long aisles of static shelving or pallet rack, visually locate items, and walk them to a packing or shipping area. Most process know-how lives in people’s heads, and when something changes, it is communicated in person or on paper. |

Basic order entry or inventory software, spreadsheets, printed pick lists, handheld RF scanners used mainly for periodic counts, pallet jacks and carts, static shelving and pallet rack. |

|

Partially automated / partially integrated warehouse |

Some parts of the process feel very manual and others feel much more streamlined. For example, operators might scan barcodes to confirm picks from an Automated Storage and Retrieval System (ASRS) such as a Vertical Lift Module, then place totes on a simple conveyor to packing. Elsewhere, pickers still walk shelving or pallet rack using paper or RF devices. Systems may share some data, but there are still handoffs where people rekey or export information. |

WMS connected to ERP or order management in some way, barcoding/RFID, one or more ASRS technologies (such as VLMs), basic conveyors or put walls, shipping software that may or may not be directly linked to WMS, simple point-to-point integrations or file exports. |

|

Highly automated / more fully integrated warehouse |

Much of the work is driven by system-generated tasks. Orders drop into WMS, which releases work to ASRS, AMRs/AGVs, or robotic zones. Goods are brought to people at workstations, where operators focus on picking, value-added services, or packing rather than walking and hunting. Exceptions still exist, but the “happy path” is largely orchestrated by software. |

WMS at the center, often connected to ERP, e-commerce platforms, ASRS (including VLMs), AMRs/AGVs, sorters, and shipping systems. You might see warehouse execution or control software coordinating material flow, hands-free or wearable devices for picking, and dashboards showing live status across zones. |

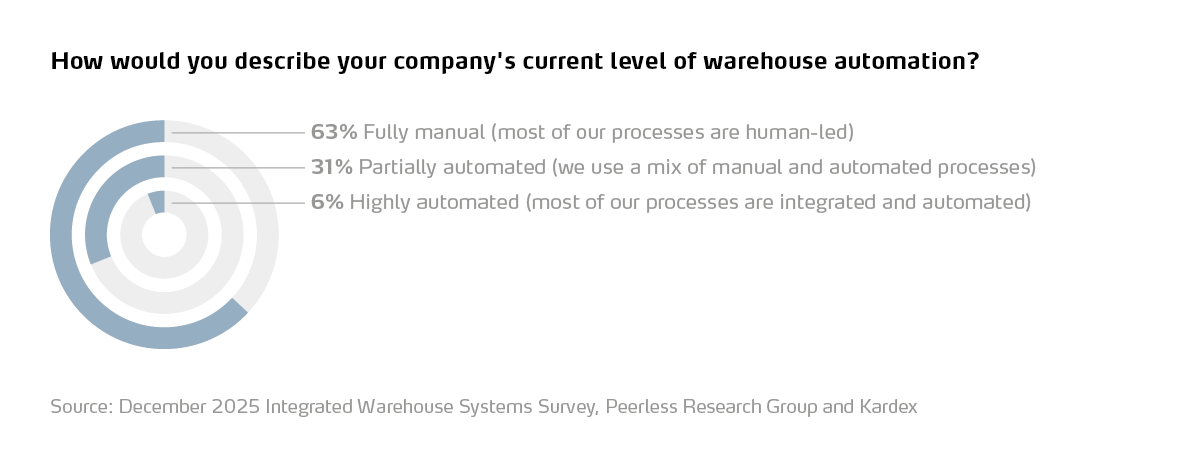

1. 63% of warehouses are still fully manual

The most eye-opening stat in the research is also the simplest:

- 63% of respondents say their operations are still fully manual

- 31% are partially automated

- Only 6% describe their operation as highly automated

In other words, if you are still relying on paper, spreadsheets, and conventional shelving, you are not behind. You are in the majority.

The industry conversation often makes it sound like everyone else has already automated end to end. The data says that is not true. Most organizations are still early in their automation and integration journey.

What this means if you are:

- Fully manual: You are not alone, and you do not need to jump straight to robots. A realistic first move is better data and visibility, or automation in one high-pain area such as parts storage or order picking.

- Partially automated: Use this as a checkpoint. You are ahead of the manual majority, but odds are you still have people retyping data, walking long distances, or working around disconnected systems.

- Highly automated: It’s time to celebrate! You are way ahead of the curve, but that’s no reason to stop pushing. Your opportunity is less about adding more hardware and more about tightening integration, standardizing processes across sites, and getting more value from what you already have.

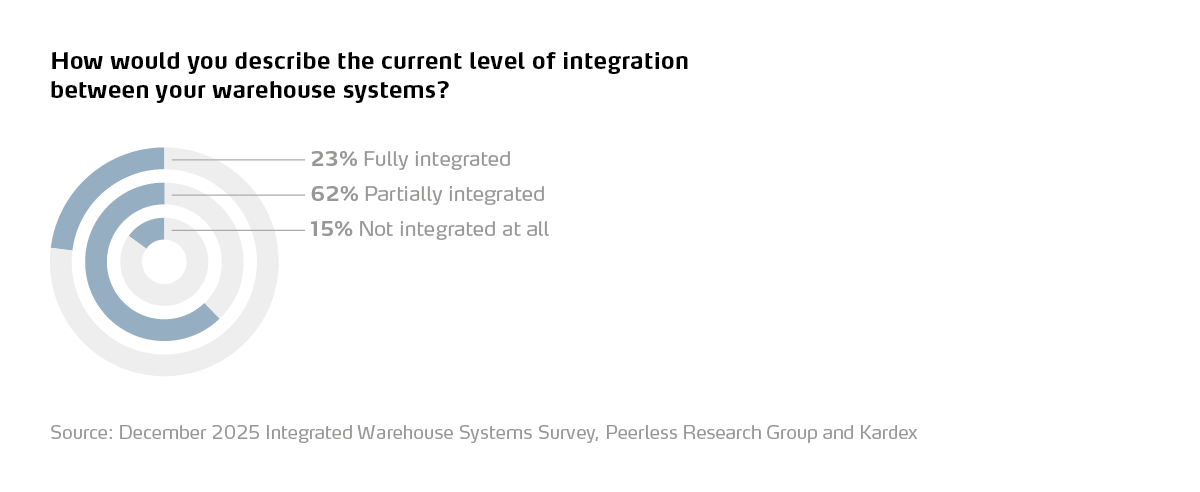

2. Only 23% say their warehouse systems are fully integrated

Automation and integration are not the same thing. You can have plenty of tech and still operate in silos.

When warehouse leaders were asked how well their systems talk to each other, the answers looked like this:

- 23% report fully integrated warehouse systems

- 62% say their systems are only partially integrated

- 15% say their systems are not integrated at all

That means fewer than one in four operations have achieved a true end-to-end integrated warehouse system where WMS, ERP, automation, and shipping tools are all connected.

For everyone else, there is still a patchwork of point solutions, manual handoffs, and duplicate data.

What this means if you are:

- Running manual or lightly automated systems: Do not aim for “fully integrated” in one leap. Your first win might be as simple as connecting WMS to shipping software or inventory to ERP.

- Partially integrated: You are in the same camp as most respondents. Your next step is to identify the two or three integration gaps that create the most manual work and tackle those first.

- Fully integrated (or close): Your focus should be on resilience, standardization, and using integrated data for better planning and continuous improvement.

Looking for more data? Head on over to our 2025 Kardex Impact survey to see what challenges modern warehouses are facing going into 2026.

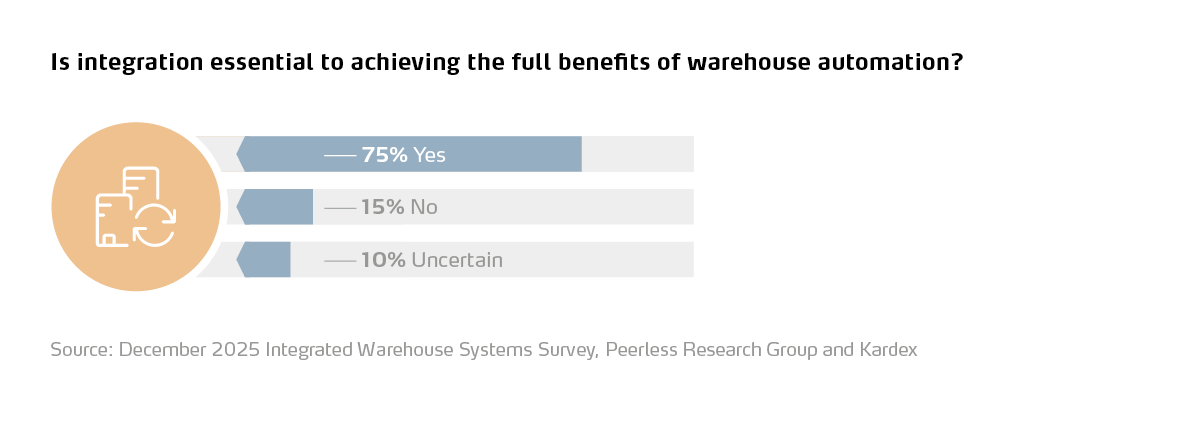

3. 75% agree integration is essential to unlocking automation benefits

Here is the twist. Even though full integration is rare, belief in its importance is almost universal.

Three out of four respondents say that integrating warehouse systems is essential to realizing the full benefits of automation.

Taken together, statistics 2 and 3 tell a clear story:

Most teams know integration matters.

And yet...

Most are not integrated yet.

That gap is exactly where the opportunity sits for 2026. You do not need to convince stakeholders that integration is important. You need to help them get from intention to execution.

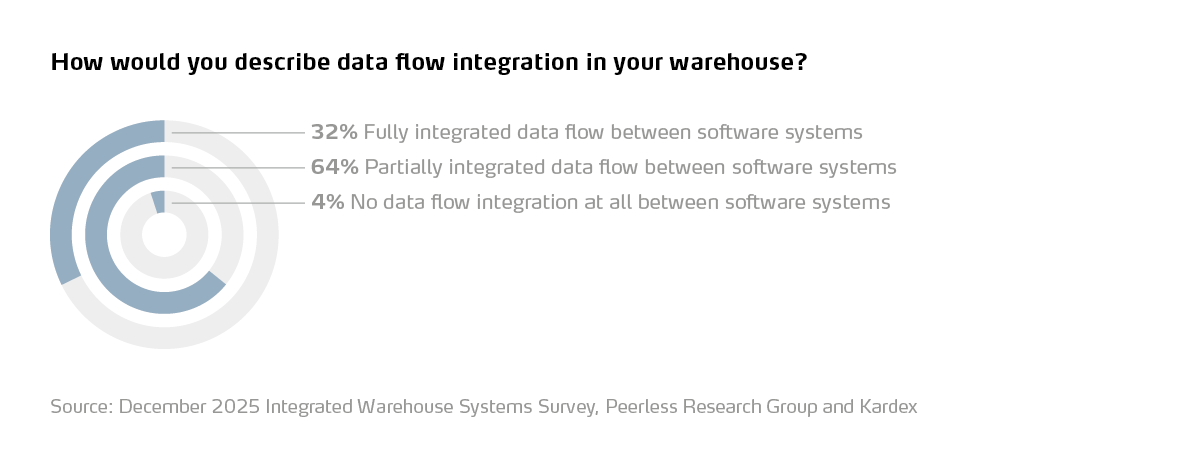

4. Software and data flow connections are still a work in progress

Even when facilities do have software in place, it is often not fully connected.

The survey found that:

- 64% of respondents say their software systems are only partially connected

- 32% say their systems are fully integrated

- 4% report that their warehouse software is not connected at all

Most organizations are living in the middle ground. They have made some progress, but there are still gaps between systems like WMS, ERP, shipping software, and equipment controls.

For 2026, that middle ground is where many teams will focus. They do not necessarily need more systems. They need better connections between the systems they already own.

Questions to ask your team:

- Where are people retyping the same data in more than one system today?

- Which two systems, if we connected them, would eliminate the most manual work or errors?

- Do we have a clear owner for integrations: IT, operations, or a joint team?

Where do you sit on the integration maturity ladder?

|

Phase 4: Fully integrated warehouse systems

|

|

Phase 3: Partially integrated systems

|

|

Phase 2: Islands of automation

|

|

Phase 1: Manual and siloed

|

Most organizations in the survey fall somewhere between stage 1 and stage 3. Only 23 percent in the “fully integrated” bucket are truly operating at stage 4.

You do not need to move from stage 1 to stage 4 overnight. A more realistic goal is to be honest about where you are now and set a two- to three-year plan to move up one stage.

5. One in three warehouses already use ASRS and other advanced automation

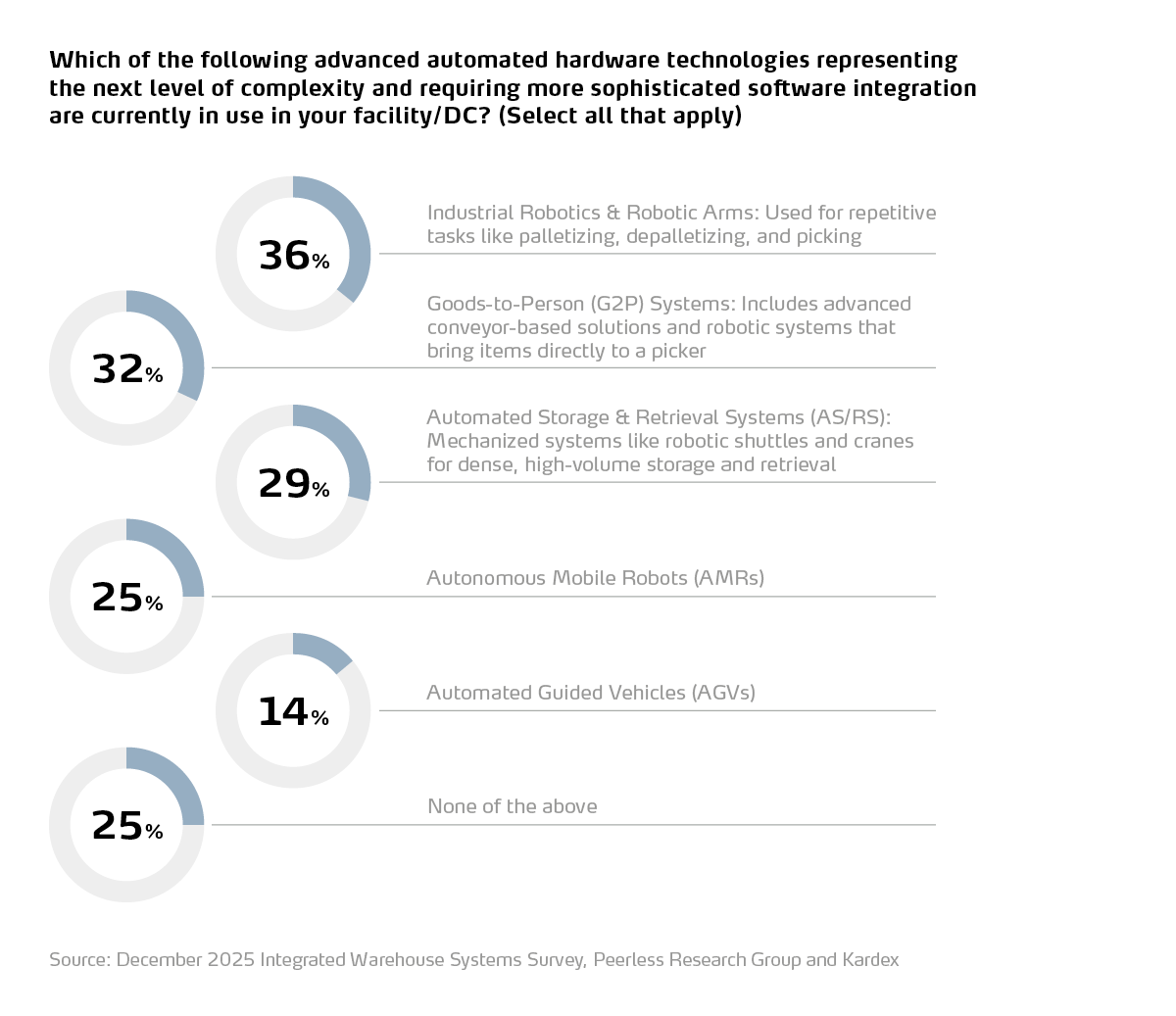

Despite the high percentage of manual operations, advanced automation is no longer niche. Among respondents:

- 36% are using industrial robotics or robotic arms

- 32% are using goods-to-person systems

- 29% are using Automated Storage and Retrieval Systems (ASRS), which includes technologies like Vertical Lift Modules (VLMs)

Couple that with widespread use of barcoding, inventory management software, and conveyors, and a picture emerges. Many warehouses already have pieces of an automated and integrated future on their floor.

The challenge is tying those pieces together into a coherent whole rather than treating each project as an island.

What this looks like in practice

A common pattern we see:

- A manufacturer replaces dense shelving with a Vertical Lift Module to save space and reduce walking in a parts room.

- At first, the VLM runs as a standalone station. Operators call up parts from a simple menu or through a basic connection to an inventory list.

- Once the team is comfortable and sees the gains in space and picking efficiency, the VLM is connected to WMS and ERP so orders, picks, and inventory updates flow automatically.

- Over time, that VLM becomes one node in a broader integrated warehouse system, not just a smart cabinet in the corner.

That progression, from “island of automation” to integrated node, is exactly what the survey data is describing.

6. Why teams integrate: cost, accuracy, throughput, and space

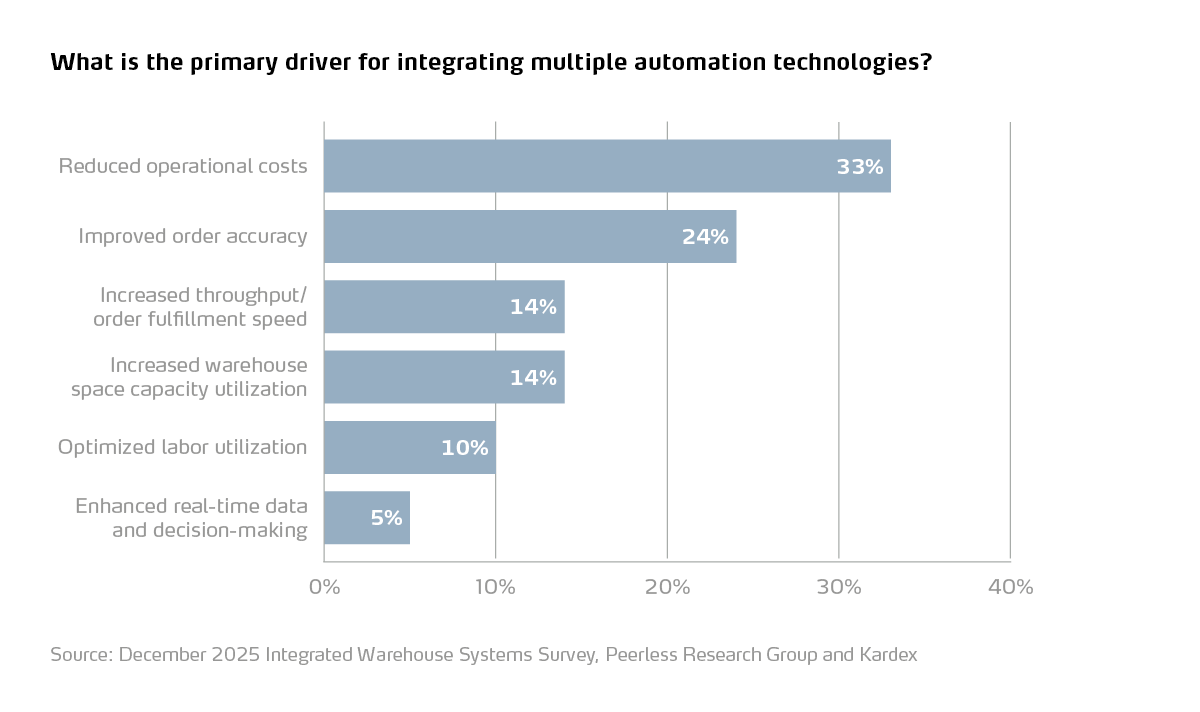

When operations leaders invest in integrated warehouse solutions, they are not doing it for buzzwords. They are trying to solve specific business problems.

Asked about the top reasons for integrating systems, respondents pointed to:

- Lower operating costs

- Improved order accuracy

- Faster throughput

- Better use of space

These four drivers line up with what most warehouse managers care about every day:

- How do we reduce cost per order?

- How do we ship the right thing, on time, every time?

- How do we keep up with peaks without burning out the team?

- How do we avoid running out of space or paying for an expansion?

Integration is not a goal in isolation. It is a means to improve these fundamental metrics.

Questions to ask your team

- Which of these four goals is most urgent for us this year: cost, accuracy, throughput, or space?

- Are we actually measuring cost per order, error rates, and space utilization today?

- If we built an ROI case around just one or two of these, which would create the strongest argument?

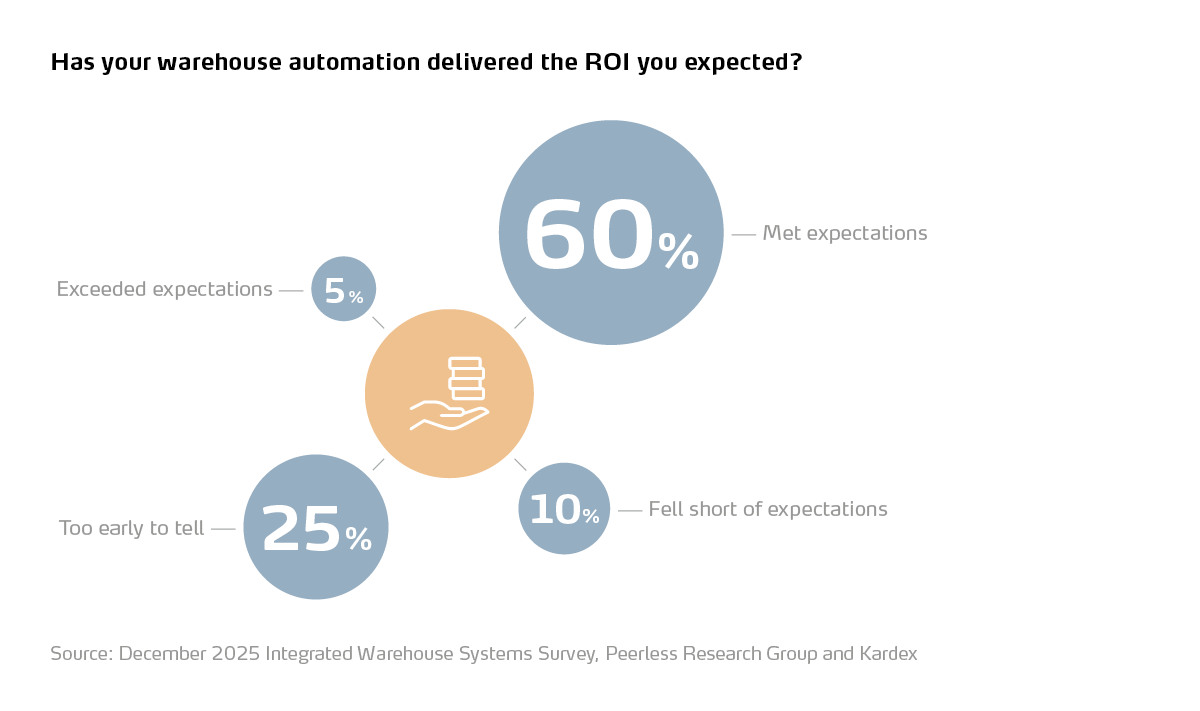

7. And it works: over 60% say automation has already met ROI goals

Skepticism about ROI is still common, especially in smaller or more manual facilities. The survey results tell a pretty encouraging story:

The survey results tell a very encouraging story: Only 10% of all respondents reported their automation has fallen short of expectations, with 65% saying it's met or exceeded expectations and the remainder reporting it's too early to tell.

That number matters in internal conversations with finance and leadership. It shows that:

- Automation and integration are not just theoretical improvements

- When projects are scoped and implemented well, they pay off

- There is a growing pool of real-world experience and case studies to draw from

For your internal business case, this stat is a useful anchor: most teams that invest thoughtfully see the return they expected.

8. The top integration challenges are about software and skills, not hardware

If the ROI is there and the intent is clear, what is getting in the way?

The research points to a familiar cluster of issues, and they are mostly on the software side:

- Complexity of integrating software from multiple vendors

- Upfront and ongoing integration costs

- Limited internal expertise to design, build, and maintain integrations

In other words, the hard part for many teams is not picking a piece of equipment. It is making sure that equipment can talk to the rest of the tech stack in a sustainable way.

That is why partner selection, proven connectors, and clear ownership between IT, operations, and vendors are going to be key themes for 2026 projects.

Questions to ask your team

- Who currently owns integration projects: IT, operations, or a mix of both?

- Have we standardized on a small set of core systems, or are we juggling many overlapping tools?

- Do our equipment vendors offer supported integrations, or are we relying on custom, one-off scripts?

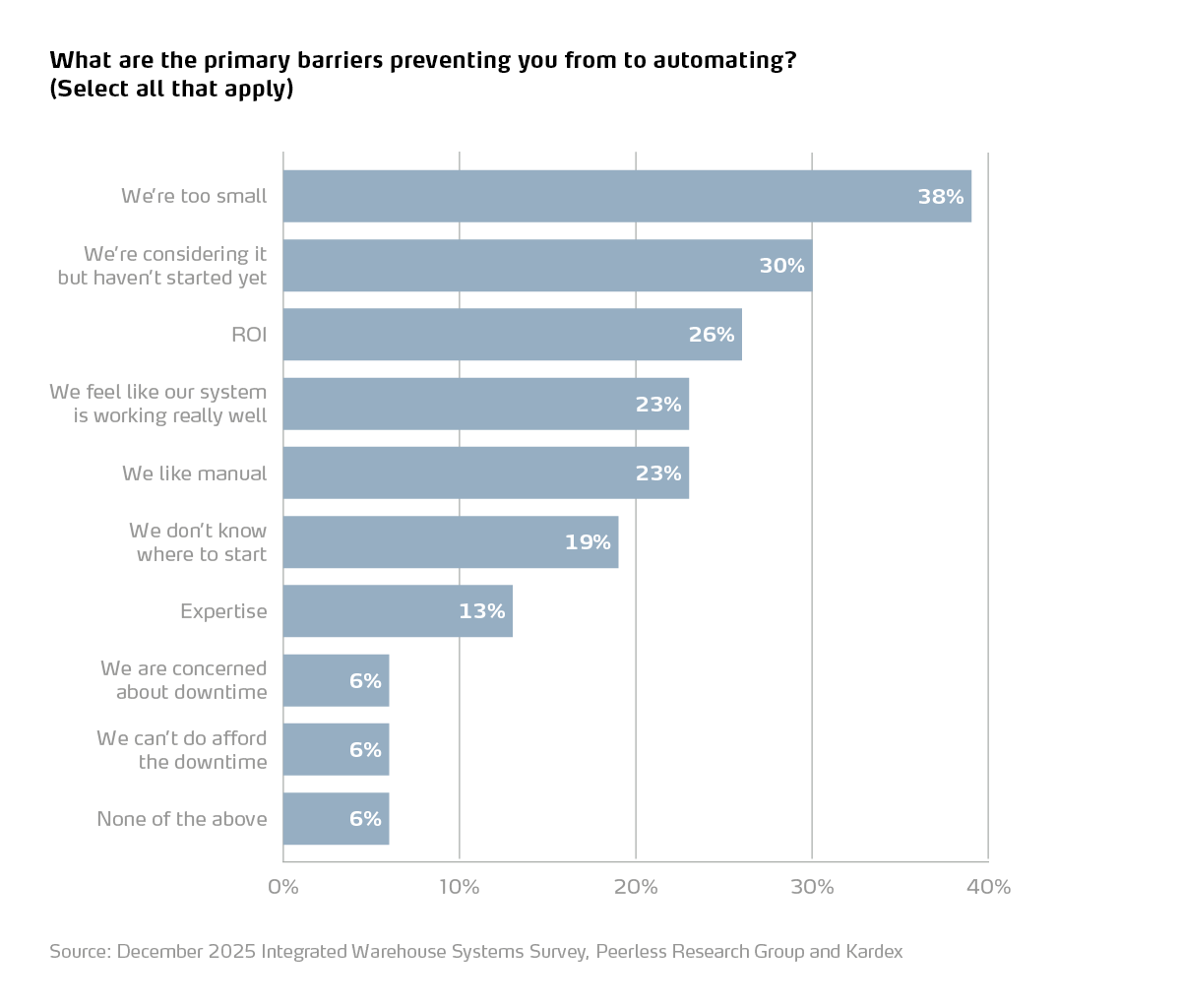

9. Manual operations feel “too small” for automation, but half still plan to integrate

Looking specifically at respondents who described their operations as fully manual, the survey dug into why they have not yet automated or integrated.

Among this group:

- A large share say their facilities are simply too small for automation

- Others cite ROI uncertainty and budget concerns

- And yet, roughly half of these manual operations still plan to integrate systems in the future

This might be the most important insight for small and mid-size operations planning for 2026:

- The belief that “we are too small for automation” is widespread

- The intention to integrate is also widespread

Compact, modular technologies like Vertical Lift Modules and other ASRS solutions, combined with phased integration, are often the bridge between those two realities. You do not need a million-square-foot DC to benefit from integrated warehouse systems. You just need a clear starting point and a realistic plan.

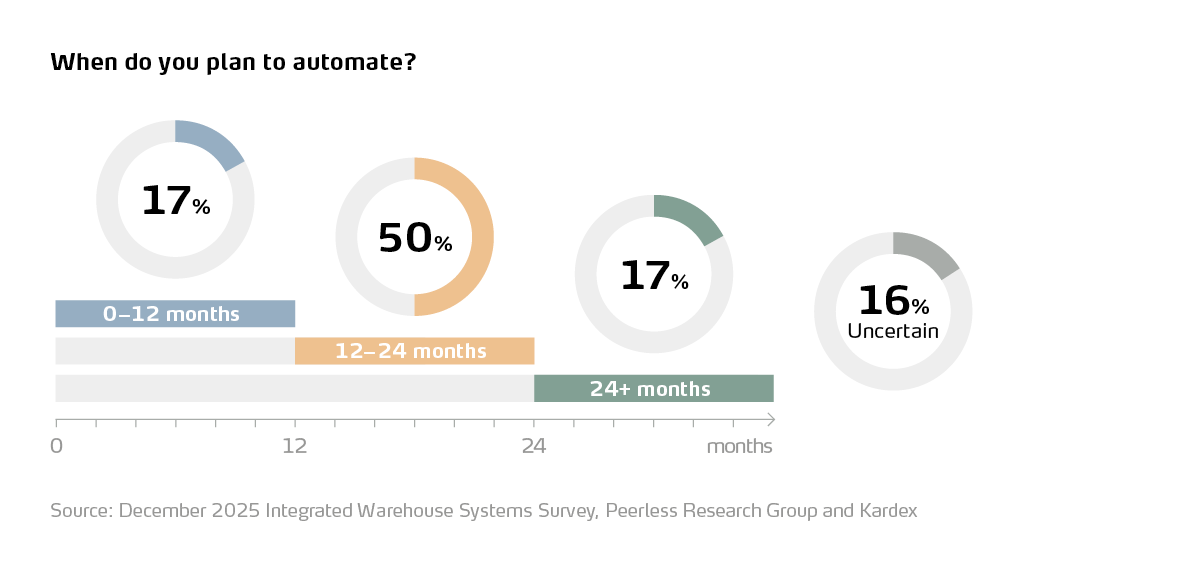

10. The next 12 to 24 months will be about connecting what is already there

Finally, the survey asked what respondents plan to do over the next one to two years.

Among organizations that are already partially or fully automated, a significant portion say they plan to further connect existing systems in the next 12 to 24 months.

That is an important signal:

- The next wave of work is not just buying more hardware

- It is tying together WMS, ERP, ASRS, robotics, conveyors, and shipping systems into integrated warehouse solutions that remove manual touches and duplicate data

At the same time, many manual operations are still evaluating their best path forward into automation and integration, rather than planning to stay manual forever.

The momentum is clear. The question is where you fit into that timeline.

What These Statistics Mean for Your 2026 Roadmap

Taken together, these numbers paint a clear picture of the integrated warehouse systems landscape:

- Most operations are still manual or only partially automated

- Fully integrated warehouses are rare, even among companies with advanced equipment

- Integration is widely seen as essential to getting real value from automation

- ROI is happening in the real world, not just in slide decks

- The biggest barriers are software complexity, skills, and perceived readiness, not lack of interest

For warehouse and operations leaders, the implication is not “you are behind.” It is “you have a lot of company, and the next few years are when the gap between leaders and laggards will widen.”

If you are mostly manual

Start with the basics:

- Clean up data and visibility

- Add barcoding or simple system connections

- Consider targeted automation in one high-impact area, such as a Vertical Lift Module for parts or order picking

If you already have islands of automation

Your next step is to connect them:

- Identify the two or three integrations that would remove the most manual effort

- Involve IT early so integration planning happens alongside equipment planning, not after

- Look at where WMS, ERP, ASRS, and shipping systems could exchange data automatically

In both cases, the survey shows you are not alone. Most organizations are somewhere in the messy middle. The advantage will go to the teams that take these statistics and turn them into a concrete, staged plan for 2026 and beyond.