Vertical Lift Module Kardex Shuttle

The Kardex Shuttle Vertical Lift Module (VLM) features an enclosed shelf-based storage system designed to increase capacity in a more compact footprint.

The Kardex Shuttle Vertical Lift Module (VLM) is an automated, high-density storage solution that delivers goods directly to the operator, eliminating wasted time spent walking, searching, and bending. Operating on the proven goods-to-person principle, the VLM dramatically improves picking speed, accuracy, and ergonomics.

With a modular, space-saving design, the Shuttle VLM maximizes vertical capacity in a minimal footprint, making it ideal for growing operations in manufacturing, distribution, and warehousing. Its flexible configuration adapts to your inventory needs over time, while intuitive controls and smart software simplify operation with minimal training. Whether you're storing small parts, tools, or sensitive materials, the Shuttle VLM boosts productivity while helping reclaim valuable floor space.

Vertical Lift Module Benefits

-

Space Optimization

Maximize vertical space and reduce your storage footprint. Store more inventory in less square footage

-

Increased Accuracy

Pick-to-light guidance ensures items are retrieved correctly, reducing errors and improving order fulfillment accuracy

-

Improved Productivity

Trays are delivered directly to the operator at high speeds, minimizing search time and accelerating picking performance

-

Scalable & Flexible

A modular design grows with your business. Easily expand capacity or reconfigure trays as inventory needs evolve

-

Safe & Ergonomic

Built-in safety features and customizable tray delivery heights support a safer, more comfortable work environment

-

Intuitive Interface

Simple touchscreen controls and smart software streamline daily operations with minimal training required

-

Proudly American Made

Our US-based manufacturing plant is based right here in West Columbia, South Carolina

-

Ships in 4-6 Weeks

Our standard-sized VLMs are available and ready to ship in 4-6 weeks as part of our QuickShip program

Space Optimization

Maximize vertical space and reduce your storage footprint. Store more inventory in less square footage

Increased Accuracy

Pick-to-light guidance ensures items are retrieved correctly, reducing errors and improving order fulfillment accuracy

Improved Productivity

Trays are delivered directly to the operator at high speeds, minimizing search time and accelerating picking performance

Scalable & Flexible

A modular design grows with your business. Easily expand capacity or reconfigure trays as inventory needs evolve

Safe & Ergonomic

Built-in safety features and customizable tray delivery heights support a safer, more comfortable work environment

Intuitive Interface

Simple touchscreen controls and smart software streamline daily operations with minimal training required

Proudly American Made

Our US-based manufacturing plant is based right here in West Columbia, South Carolina

Ships in 4-6 Weeks

Our standard-sized VLMs are available and ready to ship in 4-6 weeks as part of our QuickShip program

How Does the Kardex Shuttle Vertical Lift Module Work?

Compare Kardex Shuttle Vertical Lift Module Models

Tab Navigation

Kardex Shuttle 250/500

Flexible solution for small parts and lightweight inventory

The Kardex Shuttle 250/500 is a flexible solution for storing and retrieving small-sized inventory. With a tray width of 4,050 mm (159.5 in), the Kardex Shuttle 250/500 can handle loads up to 560 kg (1,234.6 lbs) per tray. It’s compact design allows it to adapt to space requirements, offering maximum storage capacity in a minimal footprint with a maximum height of 30 m (98.4 ft). Further, the system easily modifies to a wide range of requirements. For example, for storing goods in temperature controlled units or under clean room conditions.

Kardex Shuttle 700

Highly compact storage for medium loads

The Kardex Shuttle 700 handles a tray width of 4,050 mm (159.5 in) and loads up to 725 kg (1,598 lbs) per tray. It adjusts to a device height of 20 m (65 ft) allowing a large storage volume. The Kardex Shuttle 700 is ideal for efficiently storing and retrieving heavy tools, components or spare parts. It is extremely flexible with a number of different options that can be easily integrated before or after installation. The units can expand, decrease, modify or adapt in various ways to cater to changing needs including business growth, new applications, or a relocation.

Kardex Shuttle 1000

Manages heavy-duty loads up to 2,204 lbs

With a tray width of 4,050 mm (159.5 in), the Kardex Shuttle 1000 loads up to 1,000 kg (2,204 lbs) per tray. Achieving new load-carrying capacity standards, it's ideal for storing medium-heavy to heavy parts. Using a forklift, stack and store Euro pallets and mesh boxes in specially designed trays. This saves space and makes it possible to find goods faster, helping to lower costs, boost productivity, and increase ergonomics. A factory-installed crane can be used to move stored goods easily, decreasing working times and costs.

Vertical Lift Module Technical Data

| Kardex Shuttle 250/500 | Kardex Shuttle 700 | Kardex Shuttle 1000 | |

|---|---|---|---|

| Width in Width | 250/500 width in 62.2 to 172.5 in | 700 width in 62.2 to 172.5 in | 10000 width in 62.2 to 172.4 in |

| Width mm | 250/500 width mm 1,580 to 4,380 mm | 700 width mm 1,580 to 4,380 mm | 10000 width mm 1,580 to 4,380 mm |

| Depth in Depth | 250/500 depth in 91 to 121 in | 700 depth in 93 to 123 in | 1000 depth in 93 to 171 in |

| Depth mm | 250/500 depth mm 2,312 to 3,074 mm | 700 depth mm 2,363 to 3,125 mm | 1000 depth mm 2,363 to 4,343 mm |

| Height in Height | 250/500 height in 100.4 to 1,183.1 in | 700 height in 100.3 to 789.4 in | 1000 height in 100.4 to 789.4 in |

| Height mm | 250/500 height mm 2,550 to 30,050 mm | 700 height mm 2,550 to 20,050 mm | 1000 height mm 2,550 to 20,050 mm |

| Load lbs Load | 250/500 Load lbs Up to 1,234.6 lbs | 700 Load lbs Up to 1,598.4 lbs | 1000 Load lbs Up to 2,204.6 lbs |

| Load kg | 250/500 Load kg Up to 560 kg | 700 Load kg Up to 725 kg | 1000 Load kg Up to 1,000 kg |

| Height grid in Height grid | 250/500 height grid in 3.9 in | 700 height grid in 3.9 in | 1000 height grid in 3.9 in |

| Height grid mm | 250/500 height grid mm 100 mm | 700 height grid mm 100 mm | 1000 height grid mm 100 mm |

Customer Success Stories

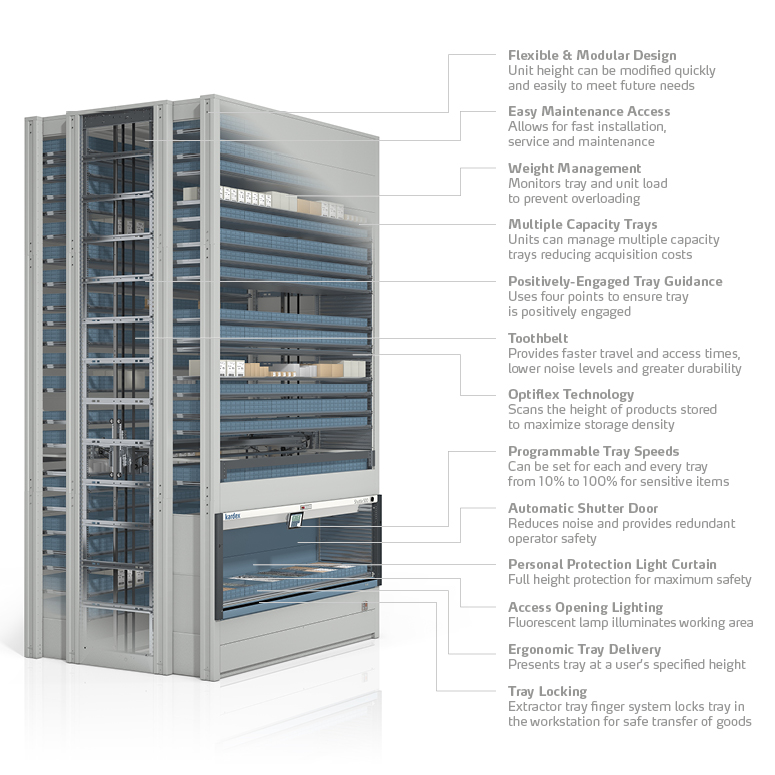

Standard Vertical Lift Module Components & Features

Every Kardex Shuttle VLM comes equipped with an automatic shutter door that closes during tray movement and opens only when a tray is safely positioned for access.

This not only protects operators by preventing accidental contact but also helps control dust, noise, and air exchange, making it a smart choice for temperature-sensitive environments or clean operations.

It’s a simple but powerful safety feature that also boosts efficiency.

A built-in light curtain continuously scans the access area for any obstruction. If anything crosses its path during movement, the system stops instantly - no buttons, no delays.

This hands-free safety layer ensures operators stay protected while working at full speed, supporting safe, uninterrupted picking throughout the day.

At the heart of the Kardex Shuttle VLM is a high-performance extractor powered by a durable, maintenance-free steel-tooth belt system. It’s engineered for speed and precision - delivering trays quickly, quietly, and reliably.

With the fastest extractor speeds in the industry, you’ll see shorter access times, smoother operations, and higher throughput across every shift.

Need to store lightweight parts and heavy components in the same unit? No problem.

The Kardex Shuttle VLM supports trays with varying load capacities - from 200 to 2,200 pounds - within a single system. This flexible design reduces the need for separate machines and adapts easily to changing inventory requirements over time.

Operators can customize their work experience with intuitive, password-protected controls.

From personalized tray delivery heights to adjustable speed settings, the system adapts to user preferences for comfort, safety, and productivity.

Whether you're managing fragile items or powering through high-volume picks, the Kardex Shuttle VLM gives your team total control.

Options for Additional Requirements

-

Position Indicator

Quickly identifies the exact pick location on the tray, helping reduce errors and boost picking speed

-

Pick-to-Light (Display LED Navigator)

A light-guided system that shows operators where to pick, improving accuracy and workflow efficiency

-

Automatic or Semi-Automatic Tray Extraction

Makes handling heavy or oversized goods easier by extending trays out for safer, more ergonomic access

-

Tray Extraction Device for Forklift Operation

Easily transfers trays to forklifts or transport carts for smoother integration into your material flow

-

Dual Tray Delivery

Deliver multiple trays to the access opening, minimizing wait times and maximizing throughput

-

Electrostatic Discharge (ESD) Version

Specially designed to safely store and retrieve sensitive electronic parts without risk of static damage

-

Outdoor Installation

Maximize indoor space by installing VLMs outside the facility with secure, weather-protected enclosures

-

Multi-Level Installation

Access stored goods from multiple floors with up to six access openings on the front and the rear of the unit

Position Indicator

Quickly identifies the exact pick location on the tray, helping reduce errors and boost picking speed

Pick-to-Light (Display LED Navigator)

A light-guided system that shows operators where to pick, improving accuracy and workflow efficiency

Automatic or Semi-Automatic Tray Extraction

Makes handling heavy or oversized goods easier by extending trays out for safer, more ergonomic access

Tray Extraction Device for Forklift Operation

Easily transfers trays to forklifts or transport carts for smoother integration into your material flow

Dual Tray Delivery

Deliver multiple trays to the access opening, minimizing wait times and maximizing throughput

Electrostatic Discharge (ESD) Version

Specially designed to safely store and retrieve sensitive electronic parts without risk of static damage

Outdoor Installation

Maximize indoor space by installing VLMs outside the facility with secure, weather-protected enclosures

Multi-Level Installation

Access stored goods from multiple floors with up to six access openings on the front and the rear of the unit

Kardex VLM Box

The modular bin system made especially for the Vertical Lift Module is flexible in height, width and depth and the layout adapts whenever your storage needs change. With the Kardex VLM Box, it is possible to create over 300 different location types with just one dividing system.

Software Solutions

The Kardex Power Pick System optimizes storage and retrieval in combination with Kardex machines. It covers multiple, smart picking strategies. By streamlining order fulfillment processes, it enhances productivity and ensures greater accuracy in high-demand warehouse environments.

.jpg)