Modern warehouses face unprecedented pressure to deliver faster, more accurate order fulfillment. Customers expect rapid delivery, whether from manufacturers or fulfillment centers, putting pressure on operations to balance speed with precision. Even with these high-pressure demands, 35% of warehouses experience a fulfillment error rate of 1% or more.

Getting it wrong can significantly cut into your bottom line. Even a single error can slash an order's profitability by as much as 13%, while about 23% of orders get returned because customers receive the wrong item. When you consider that returns alone cost $743 billion annually, it becomes clear that accuracy is essential for profitability.

Using Vertical Lift Modules (VLMs) for order fulfillment offers a proven solution to these challenges. By automating the storage and retrieval process while guiding operators through each pick, implementing VLMs for order fulfillment dramatically improve both speed and accuracy.

What is a Vertical Lift Module?

A Vertical Lift Module is a high-density, automated storage and retrieval system that uses vertically arranged trays to efficiently store goods and deliver them directly to workers. Within a VLM there are multiple trays on both sides of a central extractor. Workers can retrieve the item they want by pressing a button or scanning a bar code.

Here's a GIF that highlights how a VLM works:

Using VLMs for order fulfillment represents a fundamental shift from traditional manual "person-to-goods" fulfillment methods to automated "goods-to-person" delivery. By using the "goods-to-person" principle, VLMs eliminate time-consuming searches and reduce fulfillment errors by bringing the right items to pickers automatically.

Just take a look at this chart which compares the time spent traveling before automation, vs the time spent picking orders after automation:

Vertical Lift Module Order Fulfillment Features

Modern VLMs offer a comprehensive range of features designed to address the dual challenges of improving operational efficiency while maintaining the highest safety standards. Kardex Remstar's decades of industry experience has provided valuable insights into how warehouses can simultaneously improve both efficiency and safety outcomes through advanced storage designs.

Let's examine the Kardex Shuttle Vertical Lift Module as an example of how these features work together to transform order fulfillment operations:

1. Guided Fulfillment with Pick-to-Light Technology and LED Navigator

The Kardex Shuttle's integrated pick-to-light system eliminates guesswork from the fulfillment process. Pick-to-light guidance ensures items are retrieved correctly, reducing errors and improving order fulfillment accuracy. LED indicators show operators exactly what to pick and in what quantity, which is especially valuable when handling small parts or compiling multiple orders simultaneously.

The LED Navigator takes this further by highlighting specific tray locations and can even be configured for different languages based on the user, making it ideal for multilingual warehouses. For even greater precision, the VLM can be integrated with a laser pointer system mounted on a track at the top of the access opening. The laser travels horizontally and swivels in depth to pinpoint exact picking locations within the tray using a focused spotlight—ideal for trays with numerous parts.

This visual guidance system works seamlessly with batch picking operations, ensuring accuracy even when managing complex, multi-line orders. Take a look at this short video to see the LED Navigator in action:

2. Inventory Management Integration Capabilities

The Kardex Shuttle VLM integrates seamlessly with inventory management systems like the Kardex Power Pick System to provide real-time tracking of item locations, quantities, order history, and access controls. Through this integration, it ensures the correct SKUs are picked every time, dramatically reducing errors and eliminating time spent searching for missing inventory.

The system is designed for transparency and to enable greater efficiency. By maintaining detailed logs of every transaction, warehouses have complete visibility into stock movements for better demand forecasting and replenishment planning.

3. Barcode Scanning and Color Fulfillment

For operations that use serialized product tracking or need thorough documentation to meet regulatory compliance, the Kardex Shuttle VLM offers optional barcode scanning capabilities. This feature ensures that every picked item is verified against the order requirements, giving you an additional layer of accuracy control.

Beyond basic tracking, scan verification takes accuracy even further. With scan verification enabled, operators must scan each part before placing it into the order, confirming they've selected the correct item. While this adds an extra step to the fulfillment process, it delivers near-perfect order accuracy by catching errors at the source. This verification capability is especially critical in industries with strict regulatory requirements, such as pharmaceuticals, military supply, and medical devices.

By preventing picking errors, companies can also avoid serious compliance, safety, or operational consequences.

For warehouses that use VLMs for batch fulfillment, color-coded fulfillment systems help fulfillment teams efficiently manage orders by organizing picks based on color-coded priorities or destinations. The pick-to-light display shows a specific color, along with article information, quantity, and destination cart position. Rolling order batch carts have numbered compartments that display the same matching color as the fulfillment displays. When a batch is complete, the system automatically switches to the next color for the next batch of orders.

The system also allows several operators to work simultaneously on the same color-coded batch. This method increases fulfillment speeds dramatically without sacrificing order accuracy.

4. Dynamic Slotting for Optimal Inventory Placement

The Kardex Shuttle VLM dynamic slotting capability is one feature that can truly make the most of your VLM investment. Within the VLM, dynamic slotting uses a height sensor that measures how tall the items placed in each storage tray are every time it's put away. Integrated software crunches those numbers, then directs the VLM to store the trays dynamically—as close as one inch apart—to maximize storage density.

To speed order fulfillment, the VLM automatically positions high-frequency SKUs closer to the access opening for faster retrieval and optimizes tray placement based on actual product dimensions. The system can automatically adjust the interior storage of the VLM for optimal storage and retrieval, ensuring warehouses are getting the most out of their storage space.

Explore how added features affect the cost of your VLM in our cost considerations guide.

5. Dual-Tray Delivery

While using VLMs for fulfillment greatly improves efficiency, there are minutes lost each day due to idle time, or the time workers spend waiting for an item. To solve this problem, The Kardex Shuttle VLM offers dual-tray configuration.

While operators access one tray, the system automatically prepares the next tray for delivery. This parallel processing capability can reduce idle times while maintaining consistent fulfillment speeds throughout the operator shift.

6. Batch and Wave Fulfillment Support

Batch fulfillment is when operators fill all orders in the batch at the same time, working from a consolidated pick list, then grouping multiple orders into small batches. With batch fulfillment support, the inventory management software optimizes pick sequences to minimize travel time and maximize efficiency when processing multiple orders concurrently.

Wave fulfillment releases a number of orders simultaneously, often grouping them using specific criteria for fulfillment. The picked items are later consolidated and sorted downstream in the order fulfillment process. With wave fulfillment support integrated into your system, it allows operators to process batches of orders during specific time windows, coordinating with downstream packing and shipping operations for a smooth workflow.

7. Ergonomic and Safety Features

Any VLM used for fulfillment should prioritize operator safety and comfort with built-in features like automatic shutter doors. This feature closes the door during tray movement and opens only when a tray is safely positioned for access. A built-in light curtain continuously scans the access area for any obstruction, stopping the system instantly if anything crosses its path.

In addition, VLM trays are delivered at an optimal ergonomic height per user, reducing bending and reaching, while protecting workers from injury. The enclosed design also helps control dust, noise, and temperature, creating a better working environment.

Explore VLMs for faster picking and order fulfillment

Whether you're looking to reduce fulfillment errors, increase throughput, optimize space utilization, or improve worker safety, using a Vertical Lift Modules for fulfillment is a comprehensive solution to help address the core challenges facing modern warehouses in today’s competitive market.

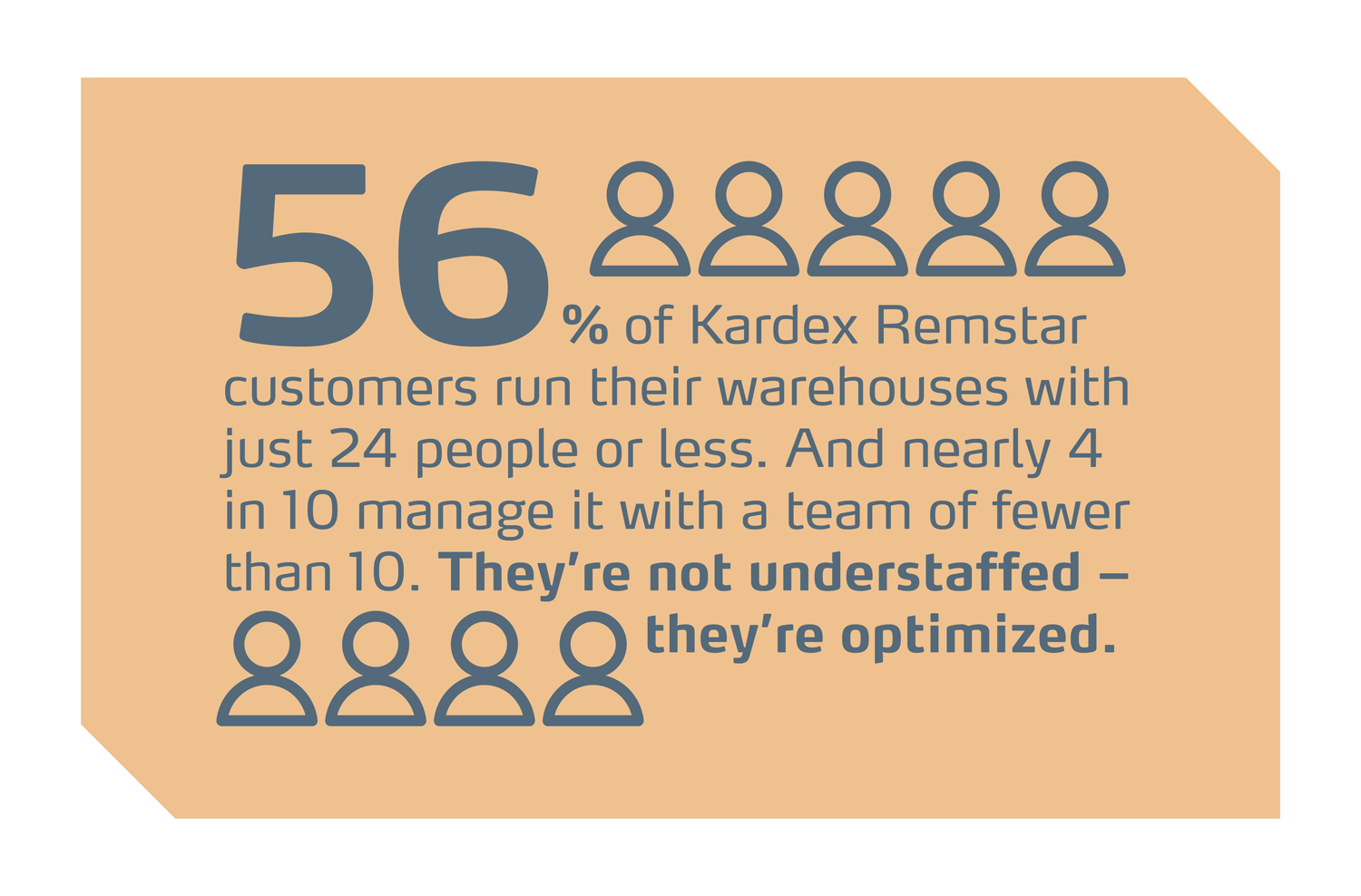

And VLMs aren’t just for mega-warehouses. In fact, in a recent survey of 100+ Kardex Remstar customers, 56% said they benefit from warehouse automation with just 24 or less workers.

Ready to see how VLMs can transform your order fulfillment operation?

Book a free site visit with our automation experts to discuss how Vertical Lift Modules can improve your warehouse operations. Our team will assess your specific requirements and discuss the solutions that can deliver measurable ROI for your operation.

Contact us today to schedule your consultation and take the first step toward more efficient, accurate order fulfillment.