Automation for Automotive and Transportation Industry

Whether you are involved in manufacturing, assembly, or MRO, Kardex' automated storage and retrieval solutions are designed to meet your specific needs, ensuring seamless operations and optimised performance.

When manufacturing automotive parts, challenges such as just-in-time delivery of parts to the production line, managing product variants and staying competitive are key. Kardex's automated solutions optimise production by ensuring timely material flow, inventory control and cost reduction.

Just-in-sequence delivery and maintaining line efficiency are key in vehicle assembly, while maintenance, repair and overhaul (MRO) focuses on 24/7 parts availability. Our solutions streamline both with parts sequencing and inventory visibility.

Features & Benefits

-

Just-in-Time

Ensure materials arrive exactly when needed in the production flow, minimising delays and bottlenecks

-

Just-in-Sequence

Deliver parts in the exact order needed, ensuring seamless assembly operations

-

Inventory Management

Always know the exact location, status, and readiness of your inventory with real-time tracking

-

Optimised Space Usage

Maximise storage efficiency with compact, high-density solutions

-

Safe Materials Handling

Prevent unauthorised access and materials damage with secure storage solutions

-

Reduced Downtime

Minimise repair times and keep operations running smoothly with efficient parts management

Just-in-Time

Ensure materials arrive exactly when needed in the production flow, minimising delays and bottlenecks

Just-in-Sequence

Deliver parts in the exact order needed, ensuring seamless assembly operations

Inventory Management

Always know the exact location, status, and readiness of your inventory with real-time tracking

Optimised Space Usage

Maximise storage efficiency with compact, high-density solutions

Safe Materials Handling

Prevent unauthorised access and materials damage with secure storage solutions

Reduced Downtime

Minimise repair times and keep operations running smoothly with efficient parts management

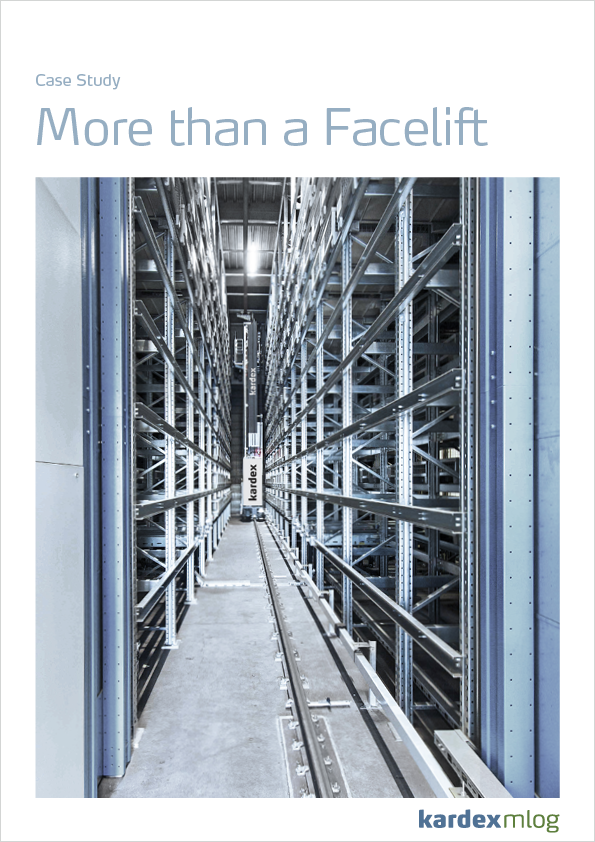

Customer Success Stories

Custom-Built Solutions to Fit Your Needs

Kardex supports the complex, high-volume demands of the automotive and transportation industries with automation solutions that streamline material flow, improve inventory accuracy, and boost operational efficiency across the supply chain.

Manufacturing: Smoother Material Flow and Space Efficiency

In fast-paced manufacturing environments, automation enables more efficient pallet handling, component storage, and just-in-time delivery. Systems designed for dynamic buffer storage ensure that materials are staged and ready for production, helping reduce delays between production and shipping. High-density vertical storage solutions allow manufacturers to store a wide variety of components—large and small—within a compact footprint while maintaining fast, reliable access.

Assembly: Precision Delivery and Improved Line Performance

For assembly operations, automation supports just-in-sequence picking to ensure components are delivered in the exact order needed. This increases accuracy, reduces picking errors, and enhances throughput on the assembly line. With flexible storage for high-turnover small parts and the ability to stage large components nearby, operations can maintain continuous flow without sacrificing space or control.

MRO: Fast Spare Parts Access and Minimal Downtime

In maintenance, repair, and operations (MRO), quick access to spare parts is critical to minimizing downtime. Automated systems streamline part retrieval by organizing inventory for fast, accurate picking. Whether managing high volumes of small components or larger equipment parts, smart storage helps ensure that the right parts are always available—keeping vehicles, machinery, and equipment in service longer and reducing disruptions.

More Solutions from Kardex

Kardex Shuttle

The Kardex Shuttle Vertical Lift Module is a flexible, space-saving solution designed for high-density storage and rapid parts retrieval—ideal for the automotive and transportation industry. It efficiently handles everything from large, bulky components to small, fast-moving service parts—improving organization, accelerating picking, and keeping production and service operations running smoothly.

Whether you're supplying parts to the manufacturing line or fulfilling dealer service orders the Kardex Shuttle adapts to your workflows with ease. Its ergonomic design reduces labor strain, while integrated software ensures real-time inventory visibility and picking accuracy.

AutoStore™ Solutions

As a global AutoStore partner, Kardex offers a modular and flexible automated storage and retrieval system (ASRS) to process orders quickly and efficiently. Optimally tailored to your structural conditions, no two AutoStore systems are the same. The compact cube storage technology can be used across industries and is redefining warehouse operations worldwide.

Automotive Interface

The Kardex Power Pick System maintains a CDK Global certified interface to support automotive dealerships using Kardex Remstar automated storage and retrieval systems (ASRS). Discover the benefits here.