It seems like every conference keynote, panel discussion, and webinar is saying the same thing:

“You need integrated warehouse systems. That’s where the real value of automation comes in.”

And on that point, at least, the industry is pretty much aligned.

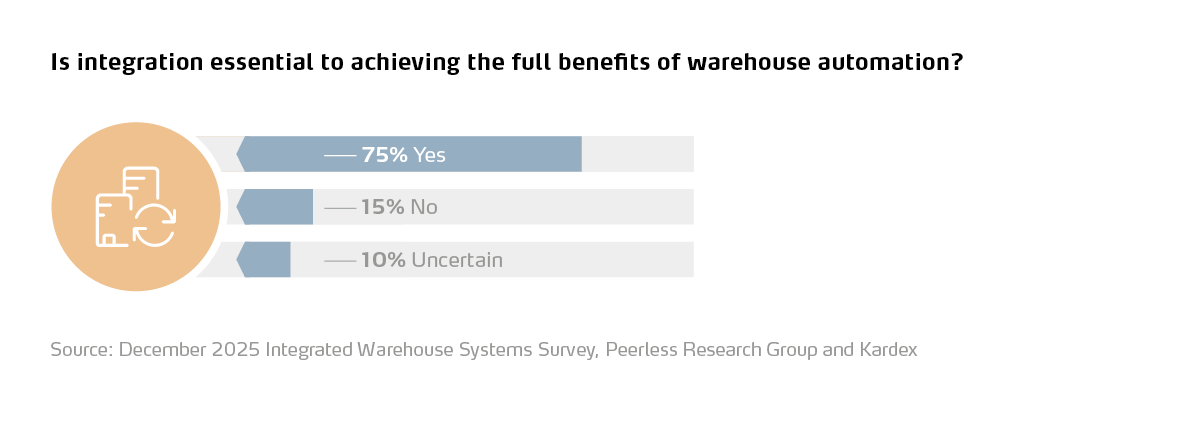

In our Integrated Warehouse Systems Survey, 75% of respondents said that system integration is essential to realizing the full benefits of warehouse automation.

And yet, when you ask those same professionals to describe their own operations, you start to get a very different picture:

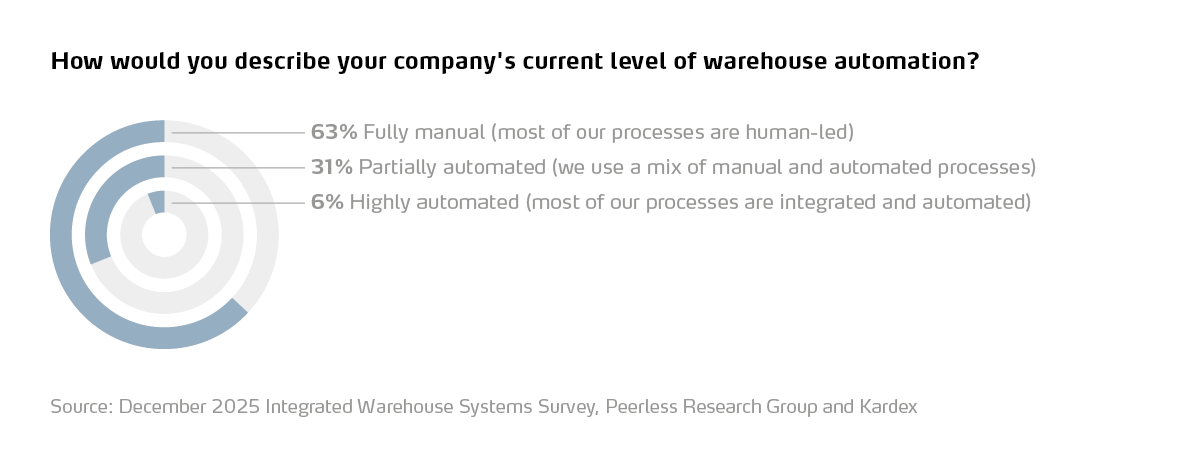

- 63% say their operation is still fully manual

- 31% say they are partially automated

- And only 6% say their warehouse is highly automated

On the integration side, the story is similar:

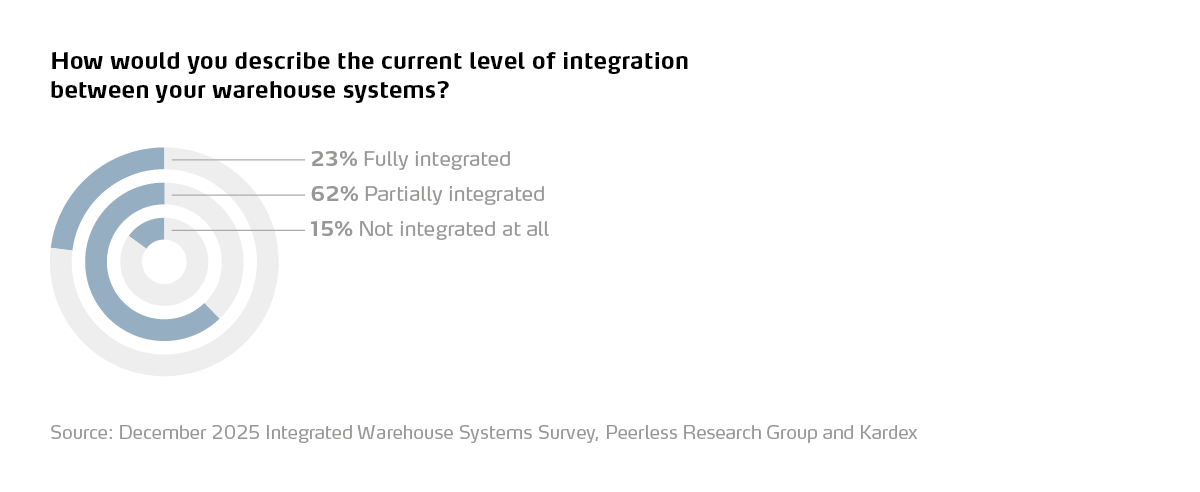

- Only 23% of respondents say their systems are fully integrated with each other

- 62% say their systems are partially integrated

- And 15% say their systems are not integrated at all

There is an important nuance here...

You can’t integrate automation equipment that you do not have. For facilities that are still fully manual, your first step on the path of building integrated warehouse systems is to introduce a focused piece of automation hardware. The next step is to connect that hardware to your tech stack, so that material and data are moving together.

And so, here is our paradox...

Everyone agrees that integrated warehouse systems are essential. But most warehouses are still manual without automation technology.

Why? What’s the reason for these gaps?

That’s what we’ll explore in this data-backed article. We’ll explore why integration really is essential, why operations say they’re still manual, and why they haven’t invested in automated technology just yet.

About the Integrated Warehouse Systems Survey

The statistics in this article come from the Integrated Warehouse Systems Survey, a research project conducted by Kardex in partnership with Modern Materials Handling and Peerless Research Group.

The survey collected 127 responses from warehouse and DC leaders across a range of company sizes, industries, and roles, including company management, operations, engineering, and IT.

Roughly half of respondents work in manufacturing, with the remainder spread across wholesale, transportation and warehousing services, 3PLs, consulting, and retail. Facility sizes range from under 50,000 square feet to more than 250,000 square feet, giving a broad view of how integrated warehouse systems are being approached in both small and large operations.

Ready to dive into the data?

Why Warehouse Integration is Important in 2026

What does an integrated warehouse consist of? Great question. This is one we explored in our survey.

An integrated warehouse system is a fully-connected warehouse ecosystem that usually includes:

- A WMS or inventory management system that manages locations, tasks, and stock levels

- An ERP or business system that exchanges orders, receipts, and financial data with the WMS

- Automated hardware systems, like ASRS (particularly Vertical Lift Modules), AMRs, conveyors, and robotic arms that receive tasks and then reports the status back to the software

- Shipping, packing, and labeling systems that pull order data directly rather than relying on re-typed info or spreadsheets

In this perfect warehouse world, software and hardware are working together.

An order drops in and then flows across each system seamlessly.

Inventory is updated as the work happens (not days later during cycle counts).

And operators are guided by system-driven tasks rather than hunting down inventory or what to do next.

This is the dream. The problem is that this is not the reality on most warehouse floors, or even close to it.

Most Operations Are Still Manual or Partially Automated

This is the reality. When we asked warehouse and DC leaders to describe their current level of warehouse automation and how integrated their warehouse systems are. The answers were pretty surprising.

- 63% of warehouses are still fully manual and 15% have no integration between systems

- 31% are partially automated and 62% are partially integrated

- 6% are highly automated and 23% are fully integrated

It’s worth noting that “manual” in this context means “no meaningful automation hardware yet” rather than no software at all. Many operations use inventory and order systems. What they lack is a first piece of automation equipment that could eventually become part of a larger integrated warehouse system.

Why Haven’t Warehouses Automated Yet?

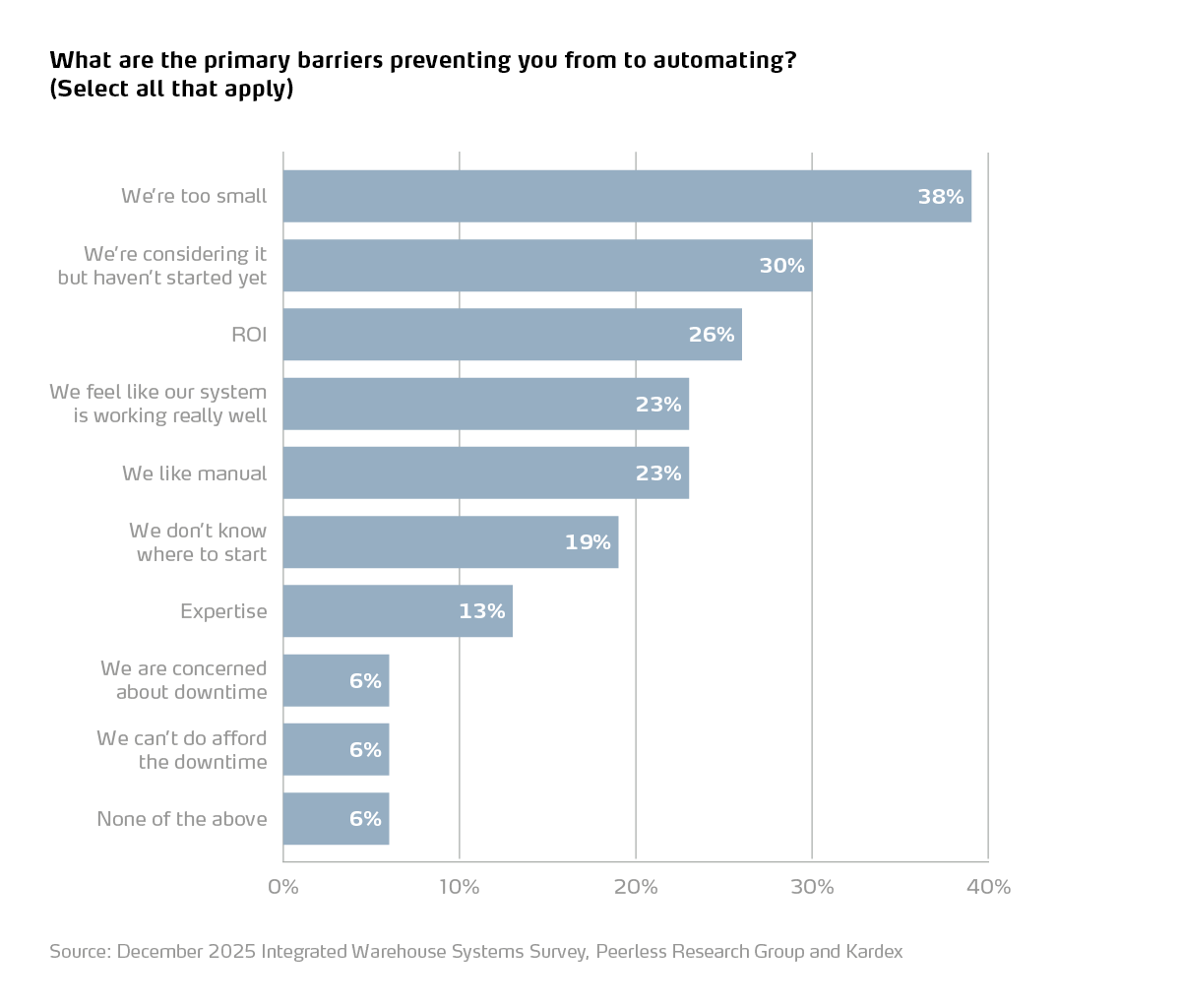

We wanted to know. So we asked.

We’ll take a look at the top four most common obstacles to automating, and then provide some insight on how you can start to work through each one.

If automation is a priority for you in 2026, this is your chance to start building your game plan.

Barrier #1: We Are Too Small for Automation

Among survey respondents who run a fully-manual operation, 38% cited that their facility was simply too small for automation.

If you run a 20,000 – 40,000 square foot building with a lean team, it’s pretty easy to assume that automation and complex software systems are for the ‘big guys’. You see all of these case studies about million-square foot e-commerce hubs with fleets of robots and think:

Yeah, that’s not us.

But our data suggests otherwise. In the same research, a significant portion of respondents said they operate facilities under 50,000 – 100,000 squre feet, and yet, many of them are already investing in automation or actively planning for it.

In our Kardex Impact Survey, which looked specifically at Kardex Remstar customers using automation, 56% said that they run their warehouse with 24% or fewer, and about a quarter run with 10 people or less.

Small teams are not the exception. And there are an enormous number of benefits to integrating basic automation technology, like Vertical Lift Modules, in small warehouse environments.

How to Move Past the ‘We are Too Small’ Barrier

Start with a Vertical Lift Module (VLM). It’s the perfect automation investment for small warehouses for so many reasons. It can immediately recover up to 85% of your floor space currently used for shelving, so that you can expand and grow without needing more footprint.

And VLMs are integration-ready but not integration-dependent. This is a huge one. Because you can run it as a standalone system and get fast ROI, and then easily connect it to more complex systems if and when you’re ready.

If you have a pain point that is costing you time, space, or people, you are big enough for a VLM.

We address this topic in more detail in our complete guide to using VLMs for small warehouses here.

Barrier #2: ROI and Cost Concerns

The second barrier is obvious: financial concerns.

Many manual respondents said that they can’t justify the cost yet or they are not quite confident in the ROI.

That’s understandable. Implementing automation and then integrating your systems can be capital-intensive, especially if you’re looking to invest in multiple pieces of equipment at once.

But our data paints a reassuring picture.

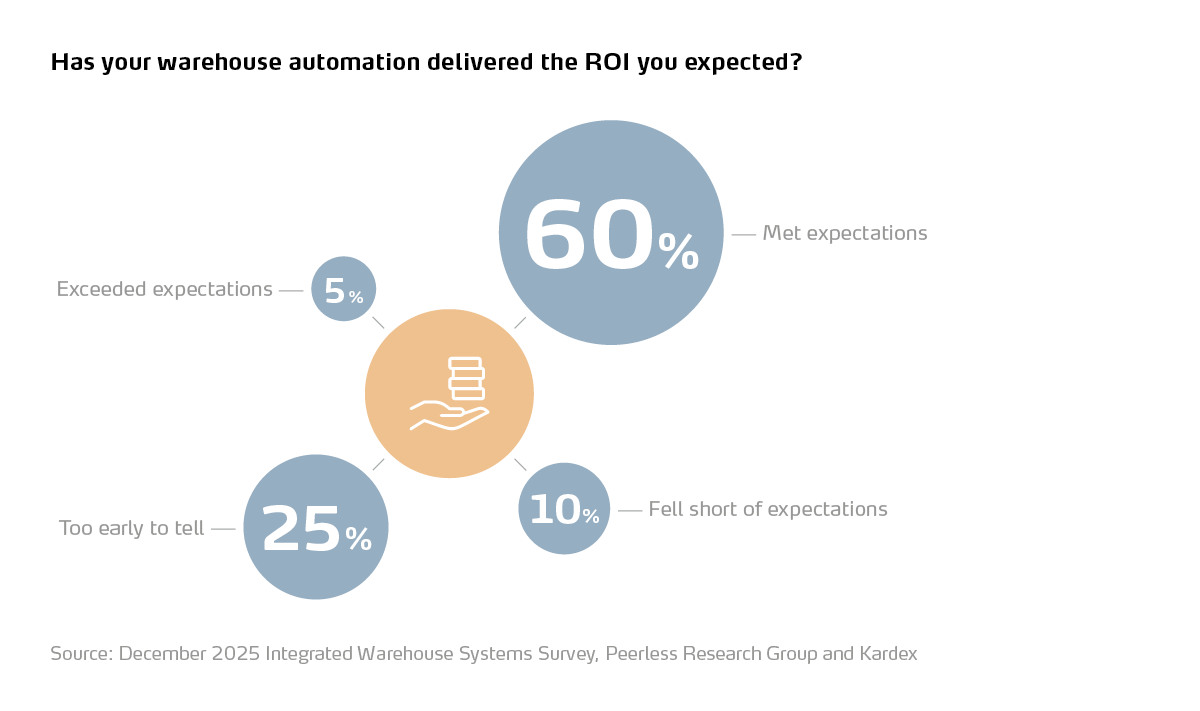

Across all respondents, more than 60% said their automation investments have already met their expected ROI. That's not a theoretical projection. These are teams that have lived through projects and are looking back at the numbers.

The challenge is that many organizations still evaluate automation primarily through the lens of initial purchase price rather than total impact. They look at a six-figure quote for an ASRS or VLM and stop there, without quantifying:

- Space saved and the cost of alternative options like expansion or off-site storage

- Labor hours avoided through reduced walking and searching

- Errors and rework avoided through better accuracy

- Reduced injuries and associated costs due to improved ergonomics

How to Move Past the ROI Barrier

This one is easy. Start small with a set of hard numbers. These will be things like your current labor costs, approximate cost per square foot, and error rates and the costs of reshipments.

Want to see how much a VLM could save your operation?

Our interactive cost justification calculator will help you determine how fast your team will see ROI from your investment.

Finally, consider more flexible financial models. Many companies, including large ones, are increasingly interested in leasing and lease-to-own models for ASRS and VLMs, which convert a large capital expense into a predictable operating cost and make it easier to pilot systems without committing all the budget up front.’

Did you know? 80% of Kardex Remstar customers achieved ROI from their investment in 12 months or less. And 33% saw ROI in the first 90 days.

Barrier #3: Software and Integration Complexity

Software. It’s not everyone’s cup of tea. 52% of respondents cited software complexity between different vendors as a top integration challenge. And a similar share selected the upfront and ongoing cost of integration work.

Things that might factor into this might be:

- A fear that you will ‘break’ your current ERP or WMS with new systems

- Not having in-house expertise to manage and oversee the project

- Past traumatizing experiences with an integration project that dragged on, went way over budget, or never quite worked as it was supposed to

So, it’s no surprise that teams decide to delay automation for fear of opening this can of worms.

How to Move Past the Software Barrier

Start with just one or two high-value connections. You don’t have to build Rome in a day. For many operations, this could look like:

- Connecting your WMS to your ERP for orders and receipts

- Connecting your WMS to your shipping software

- Connecting your WMS to a VLM

Bring IT to the table early. If they come into the project late, it could cause problems with your existing framework. And work with a trusted vendor who has experience with your setup.

Most importantly, try not to think of the integration piece of the project as an “add-on”. It’s essential to getting the full ROI from your automated systems.

Barrier #4: Competing Priorities and Limited Bandwidth

Automation and integration are on the list. But definitely not at the top of that list. And that’s just the reality for a lot of warehouse teams. Especially for those small-to-mid-sized operations where the same leaders are doing operations, IT coordination, facility management, and more.

How to Move Past the Bandwidth Barrier

Shrink the size of your first project. Pick one problem to solve, like automating slow-moving SKUs in one zone. And choose projects with visible, near-term wins. A single VLM replacing an entire wall of shelving is a super fast tangible improvement.

Lean on your external partners. Don’t pick a vendor who just sells you the equipment. Choose someone who will partner with you to provide ongoing support, maintenance, training, and optimization of your system.

The Good News: Most Manual Operations Plan to Integrate

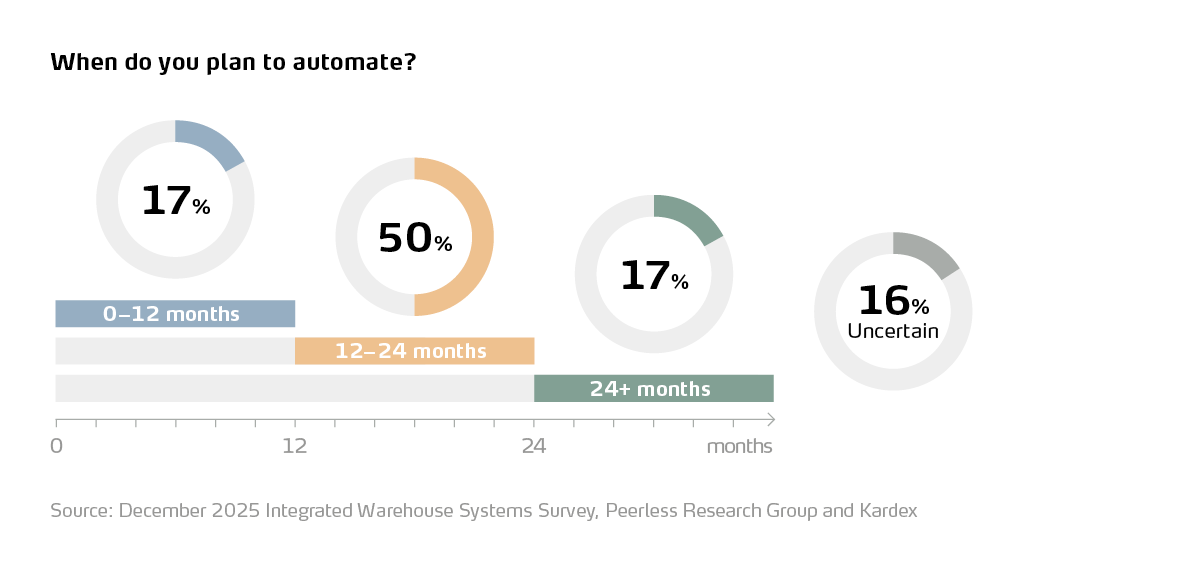

When we asked manual operations about their future plans, about half said they intend to integrate systems in the future, and many are already preparing or evaluating their options:

- 26% are preparing for future automation investments

- 47% are actively evaluating the best path forward

So the picture is not “most warehouses are manual and will stay that way.” It is:

- Most warehouses are manual today

- A large share of those want to move toward integrated warehouse systems

- But many have not yet found a path that feels achievable given their size, budget, and constraints

If that sounds like your situation, you are exactly who this data is about.

The Future of Warehouse System Integration

So, if integrated systems are “essential,” why are 63 percent of warehouses still manual?

Because it is hard. Because budgets are finite. Because software is complicated. Because people are busy. Because many facilities feel small and under-resourced compared to the stories they see on stage or in trade media.

None of those reasons make you a bad operator. They make you normal.

If you want to dive deeper into where the industry really stands, our Integrated Warehouse Systems Statistics for 2026 article walks through the key findings from the survey in more detail.

Wondering if a VLM is the right fit for your organization? We’ll send an automation expert to your facility – 100% for free – to walk your floor and help you identify opportunities to automate. See what happens during a Kardex Site Visit and how fast you can get a quote in our guide: