Buffering & Sequencing Solutions

Discover how Kardex automated solutions enable space-saving and efficient buffering and sequencing processes. Improve space utilisation, reduce packing and shipping downtime, and increase productivity with our cost-effective systems.

Warehouse and production operations use buffer systems when their processes include a wait or hold step, their material handling process requires reserve inventory to manage fluctuating demands, or when they require a quick and accurate order consolidation before packing or shipping.

Kardex offers scalable and flexible solutions that reduce operator search time, save floor space, and ensure that goods are always available at the right time.

Features & Benefits

-

Space-Saving Storage

Free up valuable floor space for more productive uses

-

Sequenced Delivery

Optimise production, packaging, and shipping with just-in-time and just-in-sequence delivery

-

Off-Hour Order Consolidation

Prepare complete, sequenced orders in advance for next shift picking or dispatch

-

Flexible Automation

Easily integrate with conveyors, AGVs, pallet shuttles, or semi-automated workflows

-

Scalable and Cost-Efficient

Start small and expand modularly as your operation grows without major infrastructure changes

-

Smart Inventory Management

Gain full visibility and control with real-time tracking and system analytics

Space-Saving Storage

Free up valuable floor space for more productive uses

Sequenced Delivery

Optimise production, packaging, and shipping with just-in-time and just-in-sequence delivery

Off-Hour Order Consolidation

Prepare complete, sequenced orders in advance for next shift picking or dispatch

Flexible Automation

Easily integrate with conveyors, AGVs, pallet shuttles, or semi-automated workflows

Scalable and Cost-Efficient

Start small and expand modularly as your operation grows without major infrastructure changes

Smart Inventory Management

Gain full visibility and control with real-time tracking and system analytics

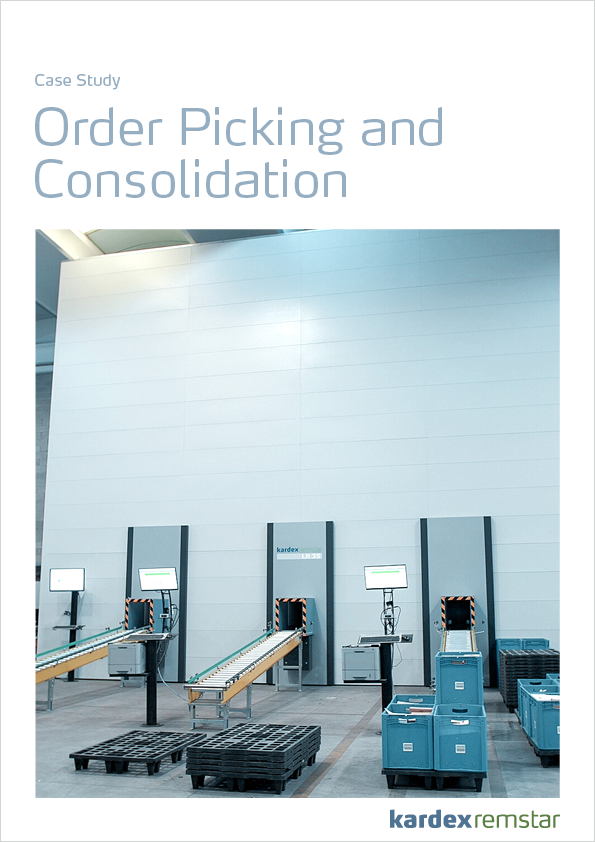

Customer Success Stories

Intelligent Material Flow in Action

Optimised Bin Buffering in Action

Custom Solutions for Production and Shipping Areas

From managing fluctuating demand in production to optimising space in dispatch zones, every operation faces different challenges. Kardex develops customised buffering and sequencing solutions that adapt to your unique environment.

From bins to pallets, our systems handle a wide range of load carriers and can be configured for intermediate storage in production, order staging, or pre-sorted delivery for packaging and shipment.

For Production Buffers

- Absorb fluctuations between process steps to prevent downtime

- Stage semi-finished goods just-in-time for assembly

- Support 24/7 production continuity with automated retrieval and return

- Consolidate and sequence orders automatically

- Stage pallets or bins in the correct loading order

- Shorten truck waiting times and increase outbound accuracy

For Shipping Buffers

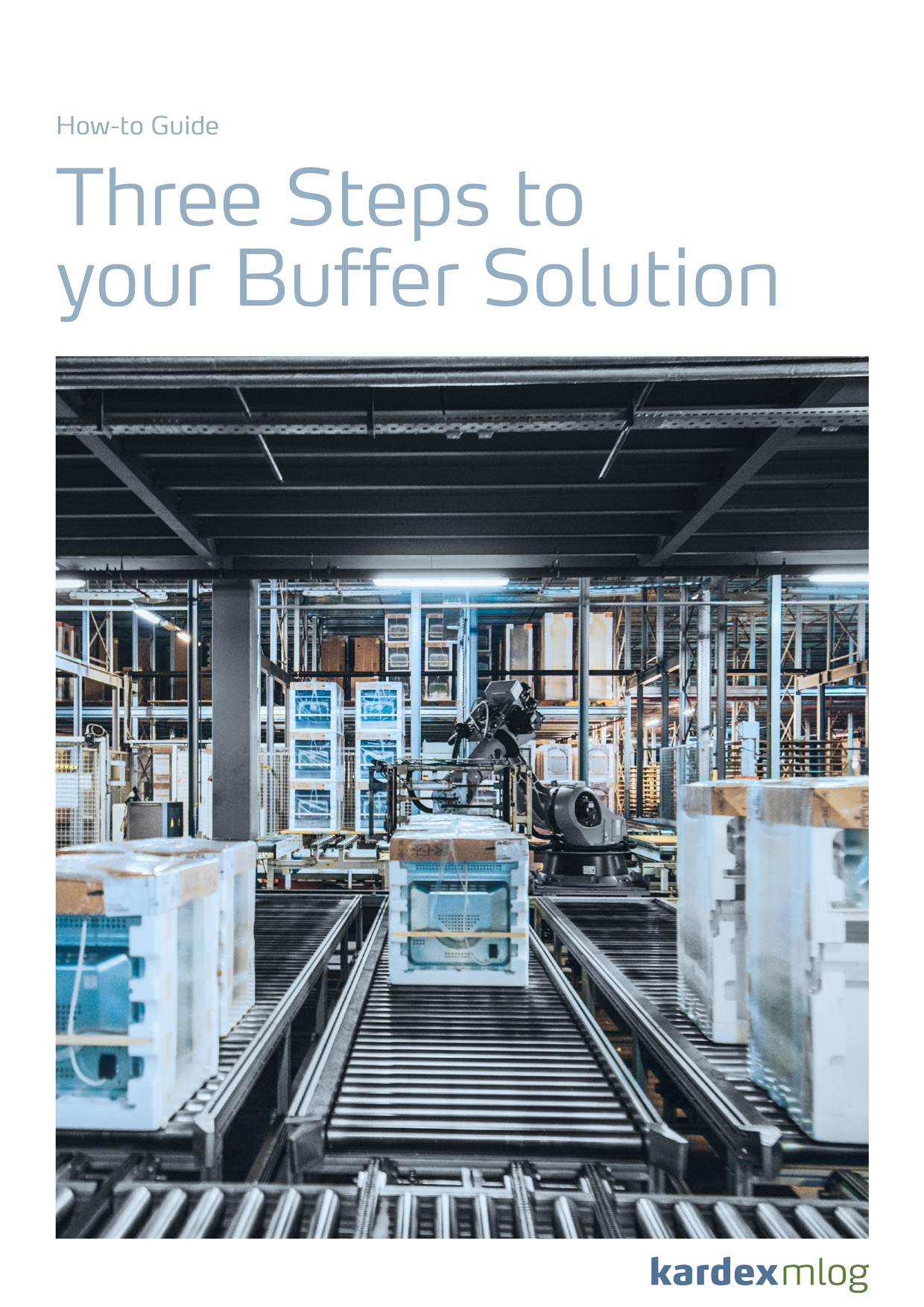

Flexible Integration and Modular Design

Kardex buffering and sequencing solutions connect seamlessly with material handling equipment such as conveyors, AGVs, and robotic systems. Whether installed in a production hall or distribution center, our modular architecture allows for step-by-step automation and scalable growth.

Automated systems can be configured as stand-alone units or integrated into a fully connected warehouse ecosystem, ensuring smooth, data-driven flows from goods receipt to dispatch.

Visibility and Performance Through Data

Integrated software solutions provide complete transparency across inventory, buffer status, and system performance. Real-time data enables predictive planning, process optimisation, and continuous improvement, ensuring your production and shipping areas run at peak efficiency.

More Solutions from Kardex

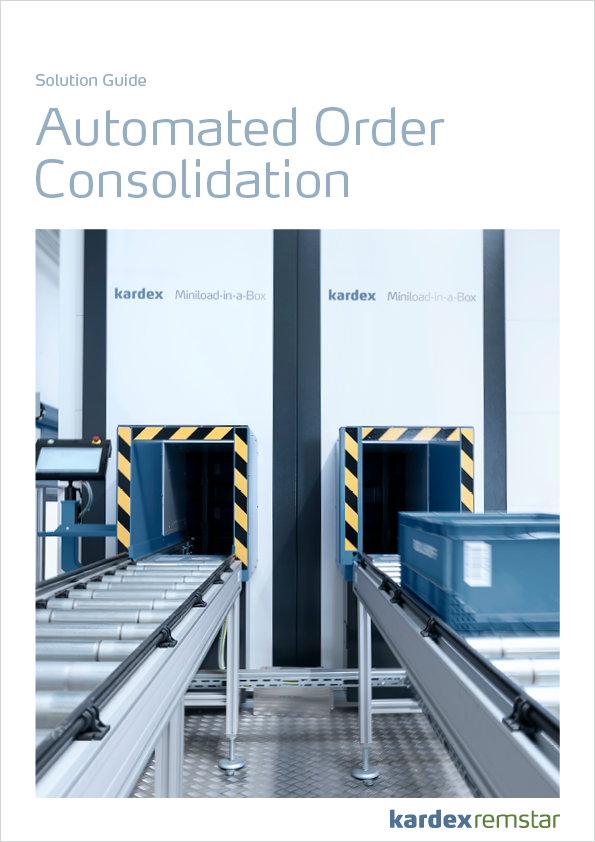

Kardex Miniload-in-Box

A flexible, compact system for storing, picking, and buffering small parts. It’s ideal when you need high-density storage, fast access, and one or more machines that can both buffer and sequence orders. With configurable openings and dimensions, it’s a strong fit for order consolidation, picking support, and outgoing-goods buffering where throughput is important but not extreme.

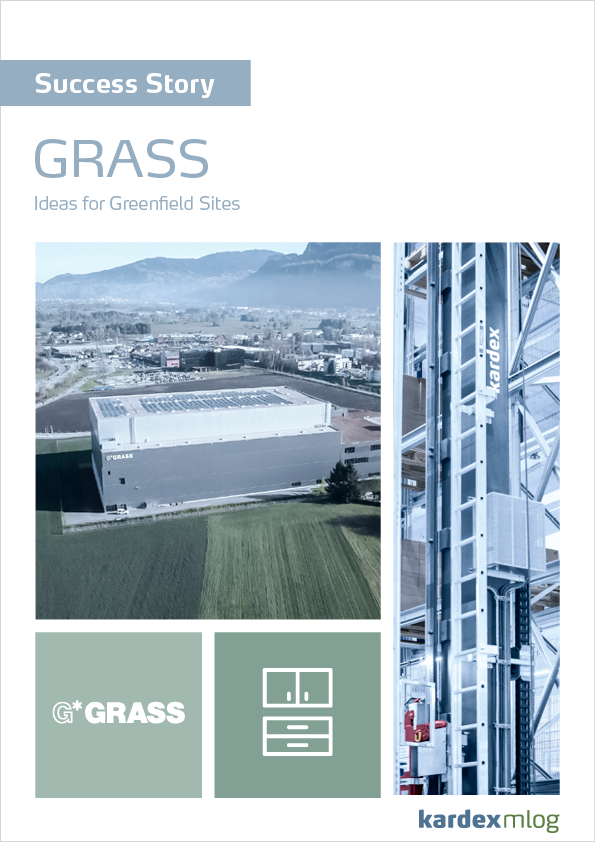

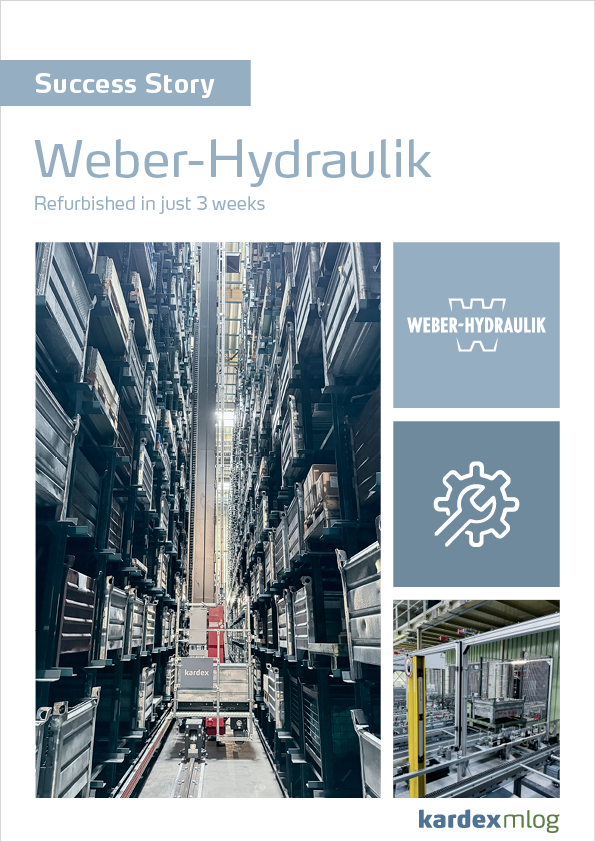

High-bay Warehouse

Whether in production supply or sequenced provision in goods issue, our high-bay warehouses enable efficient buffering and precise sequencing.

With heights of up to 50 metres, optimal use of space, and fully automated processes, they ensure stable material flows, short throughput times, and maximum process reliability.

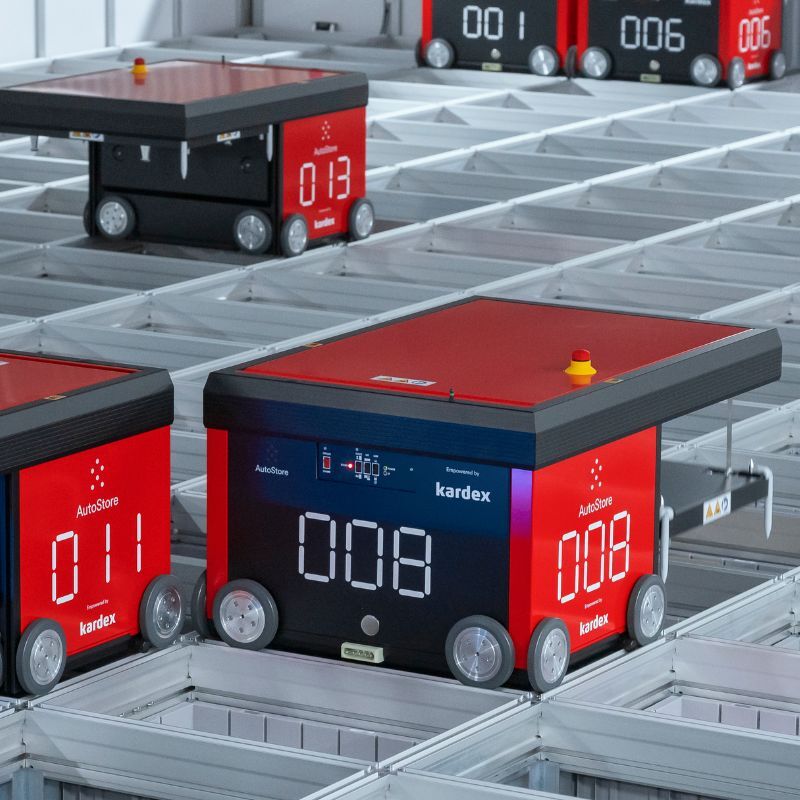

AutoStore

A high-performance storage grid for ultra-high picking volumes of small parts. Robots retrieve bins rapidly and consistently, supporting just-in-time and high-frequency picking.

With Kardex FulfillX handling sequencing, AutoStore ensures that items arrive in the correct order for packing or onward processes. It’s designed for very high SKU counts, extreme throughput, and continuous picking operations.