So, you manage a warehouse and you need to get better control over your inventory.

Inventory tracking should be easy, right?

If you’re here, it’s probably because you’ve realized that isn’t always the case.

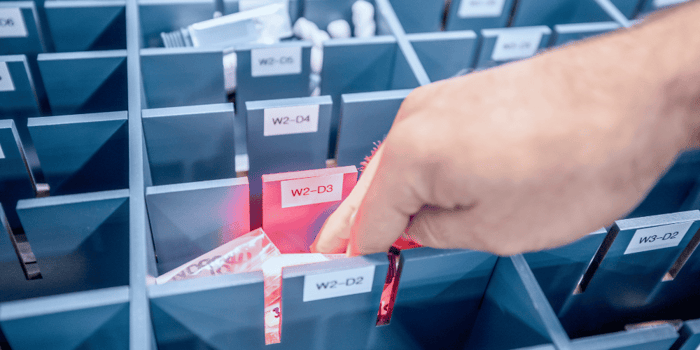

It doesn’t matter if you run a DC, manage spare parts, or need to fulfill e-commerce orders. Knowing what you have, and exactly where it is, is the foundation for the growth of your operation.

The good news? You can retire your banged-up clipboards, tired (and probably broken) spreadsheets, and all of the guesswork. In this guide, we break down how to keep track of inventory in your warehouse, the best systems available, and how technologies like ASRS with integrated software can take all of the complexity out of inventory management.

Ready to dive in? Let’s get started.

How Manual Warehouse Inventory Tracking Falls Short

Many warehouses still rely on spreadsheets or paper-based logs. While these methods can work in very small operations, they quickly become a liability as order volume and SKUs grow.

Manual tracking:

- Is prone to human error

- It lacks the real-time data you need

- It makes audits and forecasting time-consuming and sometimes downright incorrect

- It can’t support high-volume, fast-paced fulfillment

What you need is a warehouse inventory tracking system that works WITH your existing workflow, not against it. But how do you choose the right system?

Let’s take a look at the types of warehouse inventory tracking systems available, and the types of warehouses that they’re best for.

Types of Inventory Tracking Systems

Choosing the right warehouse inventory tracking system depends on your operation’s size, complexity, and level of automation. Here’s a breakdown of the most common types and what they offer:

1. Standalone Inventory Management Software (IMS)

These cloud-based or on-premise platforms are ideal for small to mid-sized operations looking to get organized fast. They track stock levels, movements, and order status, often integrating with barcode scanners and accounting software.

Core capabilities include:

- Item-level tracking with barcodes or RFID

- Basic reporting and analytics

- Manual or semi-automated replenishment

- Easy integration with handheld scanners and label printers

While these systems work well for smaller operations, they can struggle to scale across multiple warehouses or automate complex workflows. Unless they’re built with that flexibility in mind.

2. Warehouse Management Systems (WMS)

A warehouse management system (WMS) is a more comprehensive solution that controls the flow of inventory within the warehouse. It tracks receiving, storage, picking, packing, and shipping in real time.

Features often include:

- Location-level tracking (bin, shelf, zone)

- Support for multiple warehouses

- Labor and task management tools

- Integration with shipping and order systems

This type of software inventory solution is ideal for mid-to-large operations that manage high volume fulfillment or multiple facilities that need to centralize their inventory.

Looking for more information on centralizing your inventory management across multiple warehouses? We’ve got you covered!

3. ERP-Integrated Inventory Modules

Enterprise Resource Planning (ERP) systems often include built-in inventory tracking that ties into other departments like purchasing, finance, and sales.

These are best for enterprise companies seeking a fully unified business management system that goes much farther than simple inventory management.

4. ASRS-Based Inventory Tracking

Automated Storage and Retrieval Systems (ASRS) are the ideal solution for those looking to simplify and scale their warehouse inventory management system. That’s because ASRS comes equipped with inventory software that tracks every stored item, down to its serial number or lot number in real time. These automated systems completely eliminate the need for manual location checks and reduce picking errors dramatically.

Best of all? They’re easy to slot into the software solutions you’re already using. Choosing an ASRS solution with an open API means it can easily integrate into your IMS, WMS, or ERP.

ASRS-based inventory tracking is ideal for any warehouse of any size. In fact, in a recent survey of 100+ Kardex customers, 54% of ASRS users were running their warehouse with just 24 people or less.

If you’re looking to grow, scale, or secure your inventory process, ASRS is the ideal fit for you.

Warehouse Technology to Support Inventory Tracking

Once you’ve decided what kind of system you want to use for inventory tracking, it’s time to make sure it’s synced up with your storage technology.

This is where automated shelving systems can play a huge role.

Automated warehouse storage can enhance (and automate!) your inventory visibility, control, and accuracy. Having the right software is the first step. But if you really want full control over your inventory, you need the right storage technology. But which should you choose?

Here are some tips from our team of warehouse experts:

Vertical Lift Modules (VLMs)

VLMs are the workhorse of warehouse automation and inventory tracking. They consist of two columns of trays with an automated inserter/extractor that delivers trays to an operator access window. As items are stored or retrieved, the system logs every transaction. Yes, that includes item details, tray location, operator ID, and time stamp.

VLMs are ideal for high-throughput picking environments (such as distribution centers and order fulfillment hubs) with a broad SKU mix.

VLM inventory tracking benefits:

- Records each item’s exact storage location

- Tracks inventory quantities in real time

- Supports barcode or RFID scanning for added accuracy

- Integrates with inventory management software like Kardex Power Pick for seamless data access and traceability.

Vertical Carousel Modules (VCMs)

VCMs are another common choice for automated inventory tracking for warehouses. VCMs rotate carriers vertically to deliver items to a fixed access point. You can think of it a bit like a storage Ferris wheel. Your operators retrieve or store items at an ergonomically positioned window, and all movements are logged by your integrated system.

VCMs are ideal for Maintenance, MRO (maintenance, repair, and operations), and smaller inventory profiles where accessibility and visibility are important. You’ll also find VCMs heavily used for file storage, evidence storage, laboratories, hospitals, and anywhere you need to store a dense amount of similarly-sized items.

VCM inventory tracking benefits:

- Maintains detailed records of item location and movement

- Enables user access tracking for traceability

- Offers pick-to-light functionality to minimize picking errors

- Easily integrates with WMS or standalone inventory software

Vertical Buffer Modules (VBMs)

VBMs are bin-based systems that use a movable mast to retrieve totes and present them to picking stations. They are well-suited for high-speed picking and storage of small items. You might also hear them referred to as miniloads-in-a-box.

An automated miniload is right for you if you’re in e-commerce, electronics, or any healthcare application where small-item picking and rapid throughput are critical.

VBM inventory tracking benefits:

- Monitors inventory by tote, SKU, or bin ID

- Offers high-speed order fulfillment with real-time inventory updates

- Enables system-driven replenishment and tracking

- Can queue multiple orders in advance for fast picking workflows

Horizontal Carousel Modules (HCMs)

HCMs rotate bins horizontally along an oval track, quickly delivering storage locations to the operator. HCMs are ideal for using in picking pods. That’s because multiple carousels can be sequenced to reduce wait time and increase picking speed.

They’re ideal for high-throughput picking environments, such as large distribution centers and order fulfillment hubs where you house a large variety of SKUs.

HCM inventory tracking benefits:

- Logs every item movement and transaction

- Allows for batching and sequencing of multiple orders

- Provides operator accountability and location-level inventory control

- Works well with light-directed picking for enhanced accuracy

Inventory Tracking vs Inventory Traceability: What’s the Difference?

The terms "inventory tracking" and "inventory traceability" are often used interchangeably, but they serve different purposes in warehouse operations. Both are essential to building an accountable, efficient, and responsive inventory system—especially in regulated or high-volume environments.

Inventory Tracking: Tracking the Item

Inventory tracking focuses on the movement and location of products. It’s about knowing where each item is, where it’s been, and when it moved.

Examples include:

- Tracking a product from receiving to storage, picking, and shipping

- Monitoring lot or serial numbers for quality control or recall readiness

- Recording stock levels in real time to prevent overstock or stockouts

In industries like pharmaceuticals, aerospace, or food manufacturing, tracking is critical to product safety and compliance. If a recall is needed, tracking systems can quickly identify affected batches and where they were shipped.

Inventory Traceability: Tracking the Person

Inventory traceability is about who interacted with the inventory, when, and how. It links human activity to specific inventory events.

Examples include:

- Logging which operator picked or packed a particular order

- Requiring operator login or badge scans for tool access

- Monitoring usage of shared items like consumables or safety equipment

Traceability is crucial for accountability, loss prevention, and evaluating performance. In high-security or regulated environments, it can also help prevent errors, theft, or non-compliance.

Together, tracking and traceability offer a complete picture:

Tracking ensures you know where your inventory is.

Traceability ensures you know who handled it.

ASRS systems with integrated software, such as Kardex Power Pick, combine both.

They record item movements while logging operator actions through password-protected access or ID scans. This dual capability is especially valuable in industries where compliance, uptime, and accountability are essential.

How Jazz Aviation Tracks Inventory With ASRS

Looking for a real-world example of how to track inventory in your warehouse with ASRS? Jazz Aviation, a regional airline headquartered in Ontario, Canada, did just that. Jazz Aviation was in a tough spot. They needed to manage a high volume of aircraft maintenance parts and tools while maintaining strict regulatory compliance.

How did they do it? With inventory software tied to automated storage.

Jazz Aviation implemented two Vertical Lift Modules (VLMs) integrated with inventory management software to manage over 20,000 SKUs.

This setup enabled them to:

- Track every part from receiving through storage, picking, and shipping

- Record detailed metadata for each SKU, including lot number, serial number, and expiration date

- Maintain a full transaction history for audit readiness and recall support

- Monitor operator activity via login credentials, ensuring traceability and accountability

But what was the impact?

- Regulatory compliance was simplified with complete tracking and traceability records

- Downtime was reduced by quickly locating critical maintenance tools

- Accountability increased by linking inventory movement to individual users

- Operational efficiency improved, thanks to faster picking and more accurate inventory counts

This real-life use case showcases the benefits of integrating ASRS hardware with intelligent software. It allowed them to get better control over their products and personnel within a compact, automated footprint.

Practical Tips for Keeping Track of Warehouse Inventory

No matter what size your warehouse is, the foundation of effective inventory tracking lies in consistency, visibility, and control.

But what does that mean in practice? Here are several tips from our team of warehouse experts to help you maintain accurate inventory:

1. Use Barcodes or RFID for Every Item

Barcodes may be a hefty lift to implement, but they are absolutely worth it. To keep better control of your inventory, label all products, bins, and storage locations with scannable codes. Labels ensure fast, accurate updates during receiving, picking, and shipping. Barcodes are really hard to mis-scan. So you can use them to help reduce manual entry errors.

2. Implement Cycle Counting

Cycle counting isn’t just a trend. Rather than shutting down to do a physical inventory once or twice a year, cycle counting encourages smaller, more frequent counts by product category or location.

This keeps your data fresh and catches discrepancies early.

3. Standardize Your Storage Locations

One simple tip you can implement this week is to use consistent labeling for shelves, bins, and zones. Then, pair this standardization with your digital location tracking so that every item has a designated "home" in your system. And so that everyone knows where to find it.

4. Restrict and Track Access

Dealing with restricted or expensive inventory? You may want to consider limiting inventory access to authorized personnel and requiring logins or ID scans for picking and putaway. Restrictions not only improve traceability but also significantly reduce shrinkage and misplaced items.

5. Automate What You Can

Automation isn’t just for massive distribution centers. Even small levels of automation, like barcode scanning or automated reorder alerts, can make a massive impact on your operations. And consider investing in ASRS systems if you need faster fulfillment, real-time updates, or space optimization.

That investment can go a LONG way.

Did you know that 33% of Kardex users saw ROI on their Kardex Remstar ASRS in the first three months? And 80% saw ROI in the first year?

6. Keep Your Software Updated

This one is no secret. Outdated inventory software can lead to sync issues, missing features, and security vulnerabilities. Ensure your system stays current to take advantage of improvements and maintain data accuracy.

7. Set Clear Processes and Train Your Team

If your processes live in the heads of your warehouse team, it’s time to document. Turnover is higher than ever, so it’s not a good idea to rely on historical knowledge. Start by documenting your receiving, picking, and inventory adjustment processes. And make sure that you train all warehouse staff to follow the same workflows. This consistency is key to maintaining inventory accuracy over time.

How to Get Started With an Automated Warehouse Inventory Tracking System

If you’re ready to throw your laptop out the window (with your inventory spreadsheets included), then implementing an automated inventory tracking system is right for you. But how do you get started?

We asked our team of warehouse automation experts for their top tips. Here’s what they came up with:

1. Assess Your Current Challenges

Start by identifying where your biggest inventory issues arise. Are you frequently over- or understocked? Are items getting lost or misplaced? Do audits take too long? These pain points can help to guide your priorities.

2. Define What You Need to Track

Consider both inventory tracking (where items are) and traceability (who handles them). In regulated or complex environments, both are critical. But if you’re a smaller or scaling operation, you could get started with a smaller system that’s ready to scale alongside you. (More on that later.)

3. Evaluate Software Solutions

Next, you need to decide whether a standalone inventory system, WMS, or ERP integration best fits your operation. It’s a big decision. That’s why you need to know what’s important for you to track in the short and long term. When evaluating, look for features like:

- Real-time updates

- Barcode/RFID compatibility

- Location-level tracking

- Integration with automation (if needed)

Spotlight: Kardex Power Pick System

The Kardex Power Pick System is a robust standalone inventory management solution specifically designed to integrate with automated storage and retrieval systems (ASRS) like Vertical Lift Modules, Vertical Buffer Modules, and Vertical Carousel Modules.

Unlike basic IMS tools, Power Pick offers:

- Real-time inventory visibility across one or more machines and locations

- User access tracking (ideal for traceability and accountability)

- Batch and wave picking support to streamline order fulfillment

- Advanced search and filtering by serial number, lot, expiration date, and more

- Audit trails and regulatory compliance features for highly controlled industries

It’s also modular and scalable, making it easy to start small and expand as your warehouse operation grows.

Kardex Power Pick is best for companies that use ASRS equipment and need precise inventory control, traceability, and integration with their warehouse workflows, without the complexity of a full WMS or ERP.

4. Consider ASRS for Built-In Tracking

If you're struggling with space, speed, or labor constraints, ASRS solutions offer built-in tracking and traceability features. (Not to mention, significant space and labor savings...) Vertical Lift Modules, Vertical Buffer Modules, and Carousels track every movement, update inventory in real time, and require user authentication for added security. They’re perfect for small, medium, and large operations. Their modular and interconnected setup means you can start small and grow to multiple units (or multiple locations).

5. Choose a Scalable System

Whether you’re operating one warehouse or multiple, your tracking solution should be able to grow with you. Systems like the Kardex Power Pick System allow for modular expansion, user-based access control, and centralized inventory visibility. This makes them ideal for long-term growth. And it easily integrates into your WMS and ERP, so you don’t have to uproot your entire system.

Take Control of Your Warehouse Inventory

If your current system leaves you guessing, it's time to rethink your approach. You don’t have to get started on your own. Work with our team to determine what system is best for your operation. We’ll send a warehouse inventory expert to your location – totally free of charge – to evaluate your workflow and determine the best-fit technology for your setup.

Ready to take the next step? Explore how Kardex can help you design a warehouse inventory tracking system that fits your space, scales with your business, and keeps everything on track. Book your site visit today.

.png?width=700&name=USNR_ASRS_Automated_Manufacturing_ShuttleXP_03-1200x628-a0aa05d_FeaturedImage%20(2).png)