Kardex Horizontal Carousel

Use the Kardex Horizontal Carousel Module (HCM) to store and retrieve goods quickly, reliably, and cost-effectively.

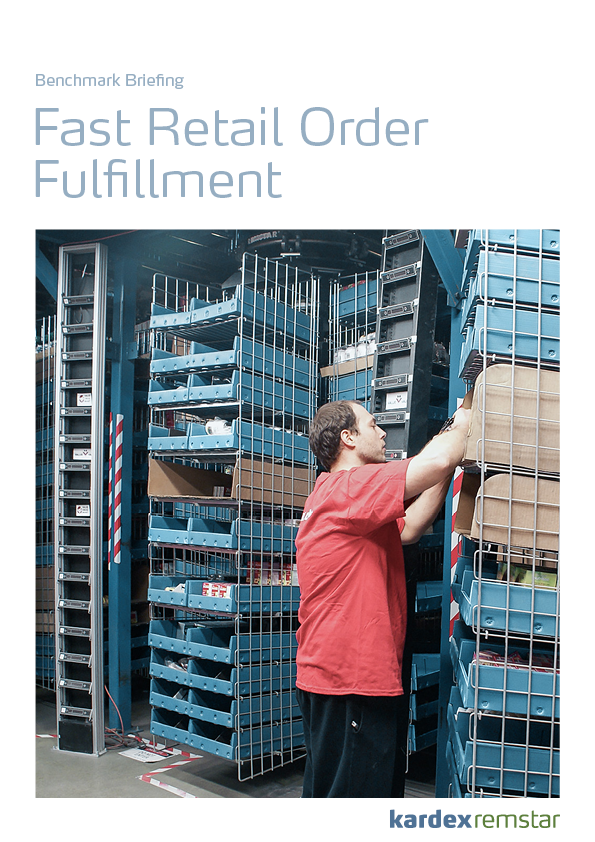

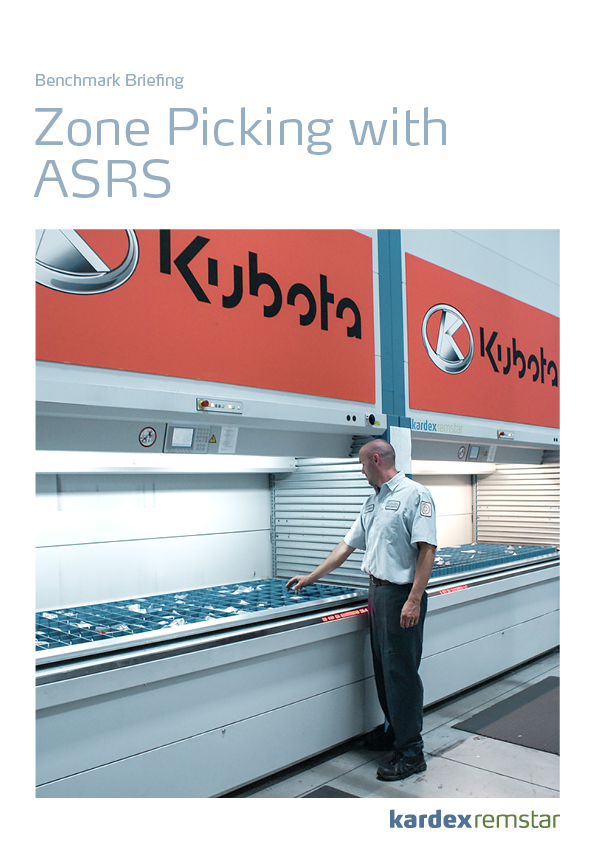

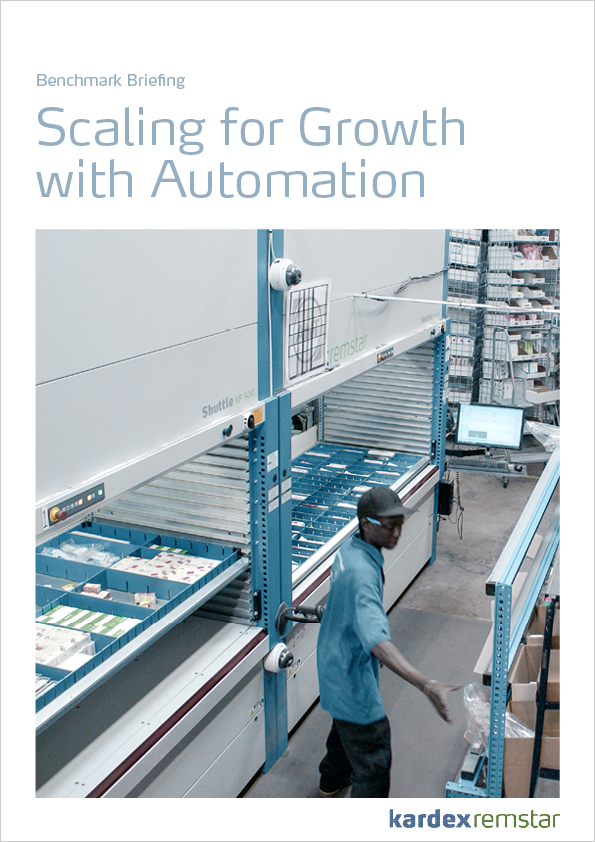

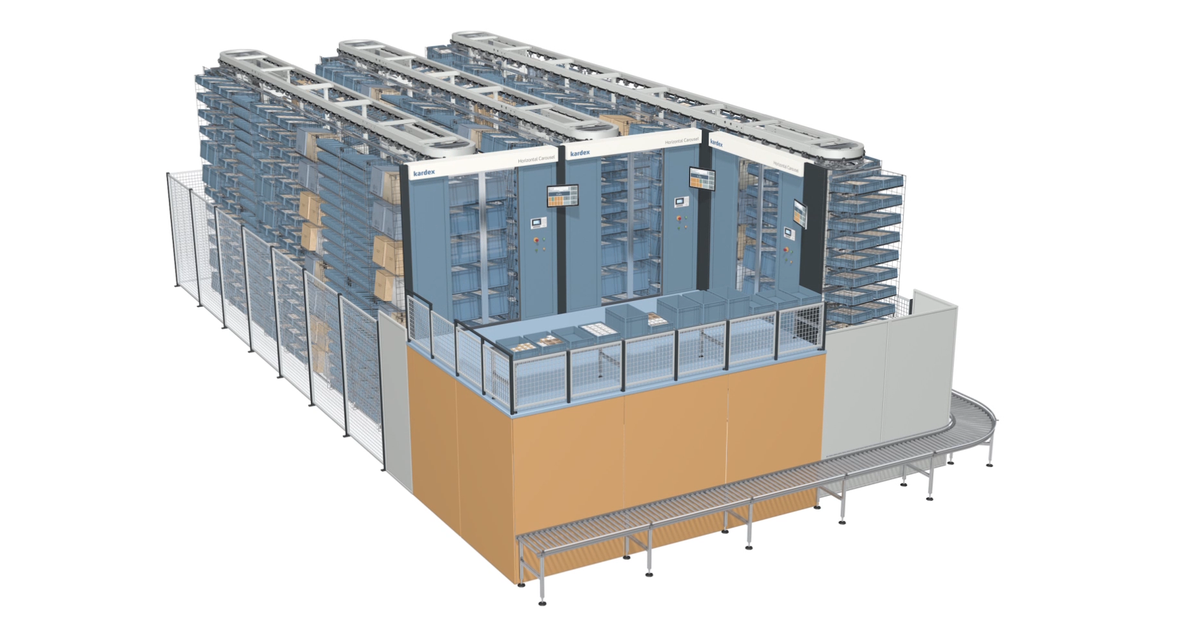

The Kardex Horizontal Carousel is built to boost productivity for facilities managing medium- and slow-moving SKUs. Ideal for high-throughput environments in production or distribution, HCMs drastically reduce travel and search time by bringing items directly to the operator—fast. With flexible workstation zoning, pick-to-light technology, and a modular design that supports everything from small parts to bulky items, HCMs adapt to your workflow while delivering exceptional picking accuracy and operational uptime.

Horizontal Carousel Module Benefits

-

High Thoughput With Batch Picking

Combine fast moving SKUs into multiple orders into a single batch and pick up to 400 positions per hour.

-

Flexible Work Zones for Peak Eemand

Easily switch between single- and multi-operator zones at the push of a button to meet seasonal or daily volume fluctuations.

-

Ideal for Heavy Payloads

Looking to store heavier items? No problem. You can easily store inventory with a maximum payload of 54 tons.

-

Excellent Picking Accuracy

Pick- and put-to-light systems ensure accuracy rates over 99%, while guided displays reduce training time and human error.

-

Optimized Space Utilization

Store items densely in just 5–10 m² of floor space, freeing up room in your facility and eliminating unproductive walking.

-

Adjustable Shelf Design for Any Inventory

Customize shelf spacing and carrier layouts to store everything from small parts to oversized items.

High Thoughput With Batch Picking

Combine fast moving SKUs into multiple orders into a single batch and pick up to 400 positions per hour.

Flexible Work Zones for Peak Eemand

Easily switch between single- and multi-operator zones at the push of a button to meet seasonal or daily volume fluctuations.

Ideal for Heavy Payloads

Looking to store heavier items? No problem. You can easily store inventory with a maximum payload of 54 tons.

Excellent Picking Accuracy

Pick- and put-to-light systems ensure accuracy rates over 99%, while guided displays reduce training time and human error.

Optimized Space Utilization

Store items densely in just 5–10 m² of floor space, freeing up room in your facility and eliminating unproductive walking.

Adjustable Shelf Design for Any Inventory

Customize shelf spacing and carrier layouts to store everything from small parts to oversized items.

How Does the Kardex Horizontal Carousel Work?

Customer Success Stories

Standard HCM Components & Features

The Kardex Horizontal Carousel Module can be configured with either front or side access openings, both equipped with safety doors that open and close automatically. These doors enhance operator safety and streamline workflow. User-friendly controls display real-time process steps, allowing for seamless confirmation and interaction throughout each pick cycle.

Each carrier is designed with tight 1.5-inch (38 mm) shelf spacing and double the number of mounting hooks, making it easy to customize for various bin sizes and inventory types. This dense configuration increases overall warehouse capacity without expanding your footprint, making the system ideal for both high-density and varied SKU storage.

Shelves rotate 180 degrees and can be installed flat or in a forward-tilted position to improve item handling. A 14 mm (0.5 in) front lip prevents goods from slipping during carousel movement.

Optional shelf locks reduce vibration noise on empty shelves and ensure secure placement, enhancing both safety and operational reliability.

To secure the work zone and prevent unauthorized access, a durable safety fence surrounds the carousel.

A built-in service door allows maintenance personnel to safely enter for inspections or adjustments—ensuring the system remains accessible without compromising security or compliance.

The integrated unit control system features a touchscreen or keypad interface that allows for simple, precise operation. Fully compatible with WMS platforms, the control system enables batch picking, inventory checks, and real-time order processing—ensuring fast, efficient performance across every shift.

Options for Additional Requirements

-

Pick-to-Light

Integrate guided light signals to direct operators to the correct pick location, improving speed and accuracy

-

Confirmation Button

Operators can confirm completed picks or returns with a touch-free button—ensuring smooth, validated workflows

-

Object Protection Light Barrier

Detects overhanging goods during rotation and automatically stops movement to prevent damage

-

Emergency Stop Button

Instantly halts unit operation at the push of a button to ensure operator safety in critical situations

-

Modular Configurations

Design flexible carousel layouts around building columns, in pods, or stacked multi-unit configurations

Pick-to-Light

Integrate guided light signals to direct operators to the correct pick location, improving speed and accuracy

Confirmation Button

Operators can confirm completed picks or returns with a touch-free button—ensuring smooth, validated workflows

Object Protection Light Barrier

Detects overhanging goods during rotation and automatically stops movement to prevent damage

Emergency Stop Button

Instantly halts unit operation at the push of a button to ensure operator safety in critical situations

Modular Configurations

Design flexible carousel layouts around building columns, in pods, or stacked multi-unit configurations

Picking Stations

Tab Navigation

Dual, Triple, and Quadruple Workstations

- Combination of between two and four Kardex Horizontal Carousels, each four meters (13.1 feet) high

- Picker transported to the retrieval location by a lifting platform

- Suitable for rooms up to 4.5 meters (14.8 feet) high

Multilevel Workstations

- A multilevel station, where two or three Kardex Horizontal Carousels are arranged above one another (each at least 2.5 meters/8.2 feet high)

- Autonomous order picking performed by one operator on each level

- Suitable for rooms up to nine meters (29.5 feet) high

Tall Workstation with Lifting Platform

- Combination of between two and four Kardex Horizontal Carousels, each four meters (13.1 feet) high

- Picker transported to the retrieval location by a lifting platform

- Suitable for rooms up to 4.5 meters (14.8 feet) high

Technical Data

| Carousel length in Carousel length | carousel length in 232.3 to 1,838.6 in |

|---|---|

| Carousel length mm | carousel length mm 5,900 to 46,700 mm |

| Number of carriers Number of carriers | CW Dependent on the carrier width (CW): |

| CW 622 mm/24.5 in | CW 622 mm/24.5 in CW 622 mm/24.5 in: 16 to 120 carriers |

| CW 825 mm/34.5 in | CW 825 mm/34.5 in CW 825 mm/34.5 in: 14 to 100 carriers |

| CW 960 mm/37.8 in | CW 960 mm/37.8 in CW 960 mm/37.8 in: 12 to 90 carriers |

| Carrier width in Carrier width | carrier width in 24.5, 32.5, 37.8 in |

| Carrier width mm | carrier width mm 622, 825, 960 mm |

| Carrier depth in Carrier depth | carrier depth in 18, 22, 24 in |

| Carrier depth mm | carrier depth mm 460, 560, 610 mm |

| Carrier height in Carrier height | Carrier height in 73 to 144 in |

| Carrier height mm | Carrier height mm 1,854 to 3,658 mm |

| Carrier height mm | Carrier height mm 1,854 to 3,658 mm |

| Carrier payload lbs Carrier payload | carrier payload lbs 992, 1,499, 1,984 lbs |

| Carrier payload kg | carrier payload kg 450, 680, 900 kg |

Software Solutions

The Kardex Power Pick System optimizes storage and retrieval in combination with Kardex machines. It covers multiple, smart picking strategies. By streamlining order fulfillment processes, it enhances productivity and ensures greater accuracy in high-demand warehouse environments.

.jpg)