Kardex Megamat

A reliable solution for high-density storage of MRO, tools, and spare parts—all in a compact vertical footprint.

Looking for high-density or compact parts storage that’s efficient, reliable, and built to last? The Kardex Megamat Vertical Carousel is designed to store and retrieve similarly sized items with speed and accuracy—making it ideal for MRO inventory, tooling, and spare parts storage.

This space-saving system uses rotating carriers to bring items directly to the operator, reducing walking, search time, and strain. With flexible configurations and a minimal footprint, it’s a go-to solution for operations that need high-capacity storage, enhanced productivity, and dependable performance over time.

Vertical Carousel Benefits

-

Fast Picking

Quickly access stored parts, goods, and inventory to reduce downtime and keep workflows moving efficiently

-

Accurate Picking

Optional pick-to-light systems and organized carrier layouts help ensure the right item is picked every time

-

Minimal Footprint

Maximize vertical space to store high volumes of inventory in a compact footprint—ideal for space-constrained facilities

-

Ergonomic Workspace

Items are delivered directly to the operator at a comfortable height, reducing physical strain and improving safety

-

Modular & Reconfigurable

Easily configure carriers for small components, bulky parts, or heavy tools—and scale as storage demands grow

-

Intuitive Interface

User-friendly controls and integration with inventory management software to boost productivity

Fast Picking

Quickly access stored parts, goods, and inventory to reduce downtime and keep workflows moving efficiently

Accurate Picking

Optional pick-to-light systems and organized carrier layouts help ensure the right item is picked every time

Minimal Footprint

Maximize vertical space to store high volumes of inventory in a compact footprint—ideal for space-constrained facilities

Ergonomic Workspace

Items are delivered directly to the operator at a comfortable height, reducing physical strain and improving safety

Modular & Reconfigurable

Easily configure carriers for small components, bulky parts, or heavy tools—and scale as storage demands grow

Intuitive Interface

User-friendly controls and integration with inventory management software to boost productivity

How Does the Kardex Megamat Work?

Kardex Megamat VCM Models

Tab Navigation

Kardex Megamat 180

Efficient storage and fast retrieval of lightweight loads

The Kardex Megamat 180 is best suited for the storage and picking of small parts. For example, it’s an excellent choice for the hotel industry, medical sectors, vehicle manufacturing, mechanical engineering and the electronics industry.

Kardex Megamat 350

Ideal for medium-sized loads

The Kardex Megamat 350 works well in a variety of different areas. It’s an excellent choice for the medical sectors, vehicle manufacturing, mechanical engineering, and the electronics industry-but can also integrate into the production process in several ways. Ideal as an interim storage solution for semi-finished products or as a buffer storage between production steps.

Kardex Megamat 650

For heavy loads of up to 650 kg per carrier

The Kardex Megamat 650 works well for heavier duty needs. It’s an excellent choice for the vehicle manufacturing, mechanical engineering, and the electronics industry-but can also integrate into the production process in several ways. Whether as a storage buffer during drying phases, bulky parts storage, or as an interim storage solution for semi-finished products.

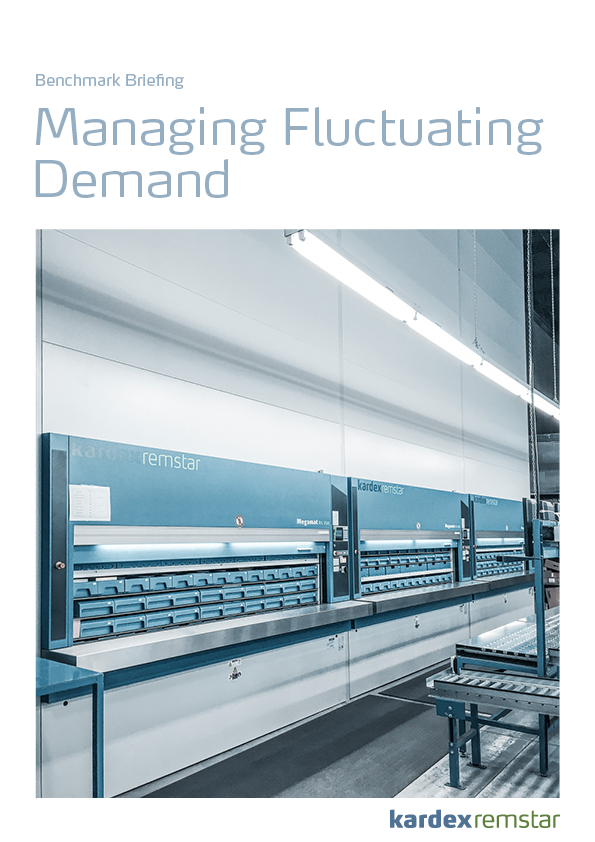

Customer Success Stories

Looking for Document Management and Mixed Media Storage?

Check out our Office Solution Megamat, formerly Lektreiver, for automated media storage for files, videos, CDs, DVDs, and so much more.

Standard VCM Components & Features

Every Kardex Megamat Vertical Carousel comes equipped with a standard mechanical sliding door designed for safe, one-handed operation.

The door is lockable, tilt-free, and ergonomically built to ensure smooth user access without compromising on safety.

This feature supports efficient workflows while helping protect users and stored items during operation.

A light curtain is installed on both the left and right sides of the access opening, providing full-area protection.

If a person or object interrupts the light beam, the machine stops instantly—protecting users and preventing potential damage to items that may protrude from a carrier. It's an essential safety feature that enables fast, secure access to stored goods.

The Megamat features an advanced imbalance load monitoring system that continually tracks the unit’s load distribution. If an unsafe imbalance is detected, the system automatically halts operation and alerts the operator with clear visual indicators.

Color-coded notifications (green, yellow, red, and error) guide users in balancing loads quickly and correctly—helping avoid downtime and ensuring safe storage practices.

TIC is the Megamat’s intuitive, web-based machine control center—offering a user-friendly touchscreen interface with built-in keyboard and tile-based navigation. Designed for simplicity and flexibility, TIC allows you to assign user roles, choose preferred languages, and guide operators through system alerts in real time.

It runs independently through a browser without requiring additional PCs or software, making it a powerful control solution for customers who don’t need a full warehouse management system. Ergonomic, scalable, and easy to upgrade, TIC delivers modern control without complexity.

Options for Additional Requirements

-

Automatic Sliding Door

Allows hands-free operation with timed, keyboard, or system-controlled opening—required for units with multiple access points

-

Confirmation Bar or Button

Choose between a full-width touch bar or overhead button to confirm picks quickly and accurately at the workstation

-

Emergency Hand Crank

In case of power failure, a plug-in crank handle enables manual movement of carriers to maintain limited access to inventory

-

Pick to Light LED Navigator

Guides operators to the correct pick location using light signals—improving accuracy, speeding up retrieval, and reducing picking errors

-

Multiple Access Openings

Equip the unit with front and/or rear access points to support multi-level operations or multiple picking stations

-

Multiple Carrier Options

Choose from a variety of carrier sizes and weight capacities to match your inventory needs—ensuring optimal storage flexibility and performance

Automatic Sliding Door

Allows hands-free operation with timed, keyboard, or system-controlled opening—required for units with multiple access points

Confirmation Bar or Button

Choose between a full-width touch bar or overhead button to confirm picks quickly and accurately at the workstation

Emergency Hand Crank

In case of power failure, a plug-in crank handle enables manual movement of carriers to maintain limited access to inventory

Pick to Light LED Navigator

Guides operators to the correct pick location using light signals—improving accuracy, speeding up retrieval, and reducing picking errors

Multiple Access Openings

Equip the unit with front and/or rear access points to support multi-level operations or multiple picking stations

Multiple Carrier Options

Choose from a variety of carrier sizes and weight capacities to match your inventory needs—ensuring optimal storage flexibility and performance

Carriers

Tab Navigation

Standard Carrier

Depending on the model, carriers support 397 lb., 772 lb., or 1,433 lb. capacities and feature a standard galvanized finish with an optional painted coating.

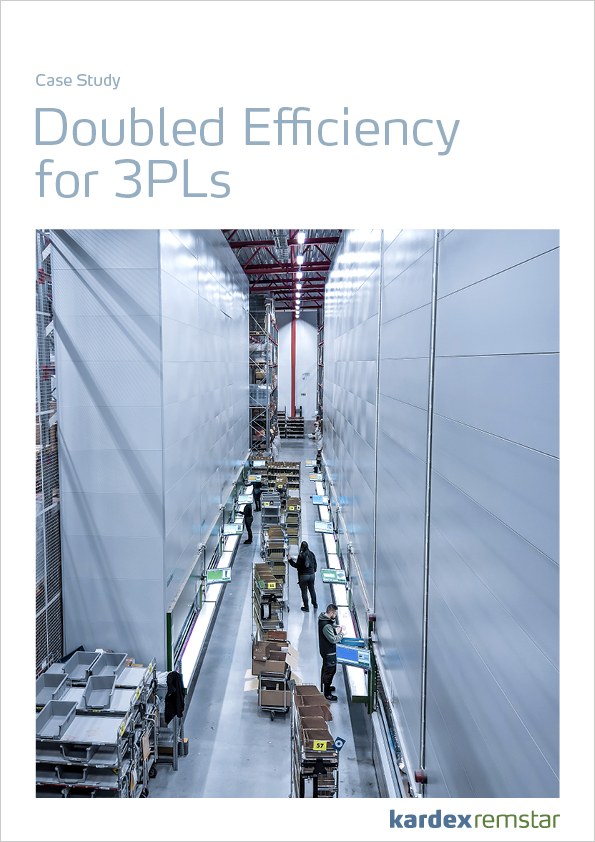

Intermediate Shelf

Intermediate shelves may be added to the carriers so that you can create multiple storage levels to maximize the storage capacity. We offer non-reinforced shelves and reinforced shelves.

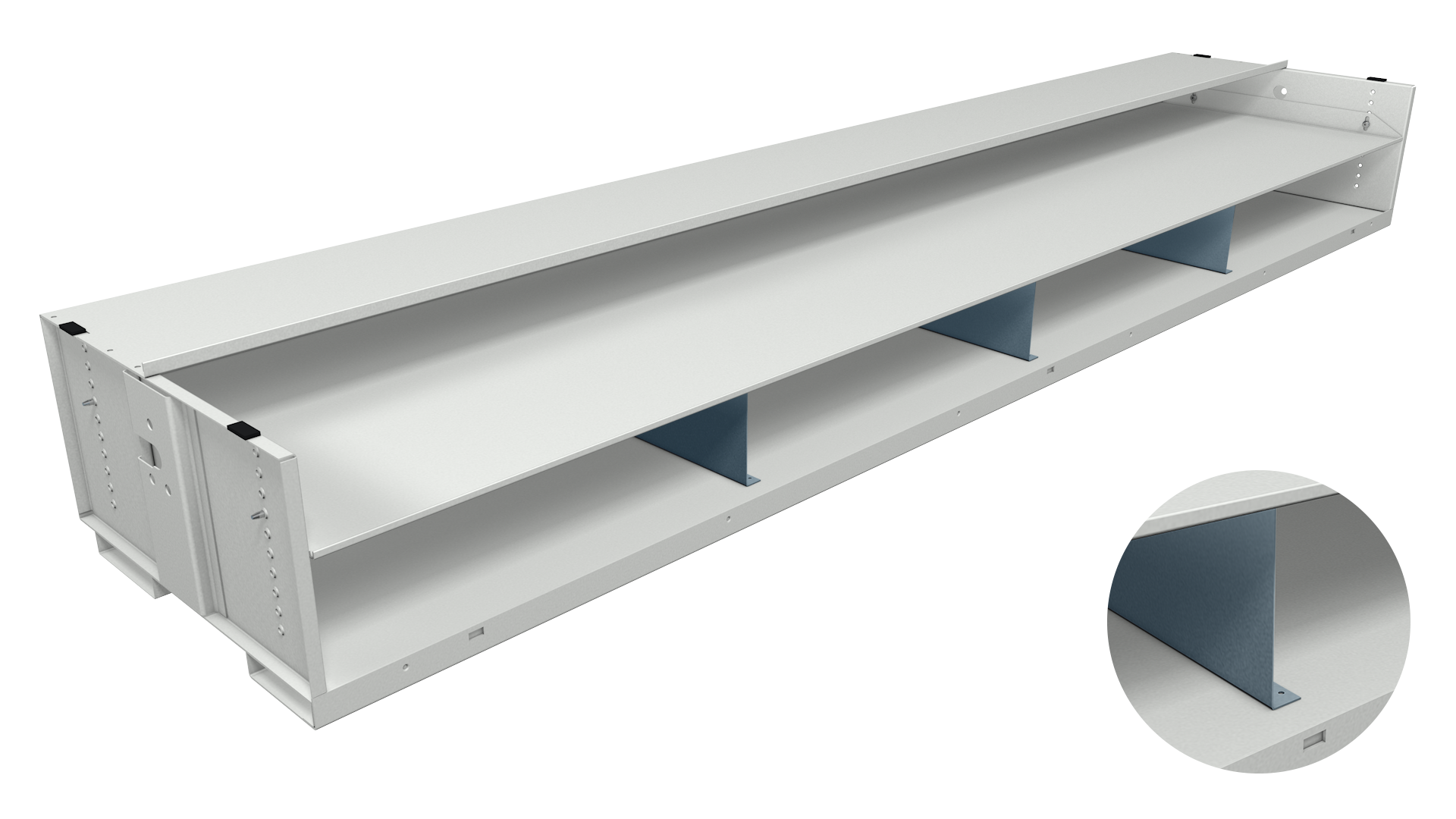

Adjustable Dividers

Adjustable dividers can be ordered to separate the carrier from left to right. Dividers can range in height from 2.87” to 11.73” and are adjustable on 1” centers.

Drawer Inserts

Carriers can be configured with drawer inserts. These drawer inserts make it easier to store small parts. Many depths, widths & heights are available .

Technical Data

| Kardex Megamat 180 | Kardex Megamat 350 | Kardex Megamat 650 | |

|---|---|---|---|

| Width | 73.8 to 152.6 in | 73.8 to 168.3 in | 77.8 to 168.3 in |

| 1,875 to 3,875 mm | 1,875 to 4,275 mm | 1,975 to 4,275 mm | |

| Height | 87 to 295.7 in | 92.9 to 394.1 in | 92.9 to 934.1 in |

| 2,210 to 7,510 mm | 2,360 to 10,010 mm | 2,360 to 10,010 mm | |

| Depth | 49.3, 56.7 and 64.2 in * | 50, 57.9 and 65.8 in * | 51.6, 59.5 and 67.3 in* |

| 1,251, 1,441 and 1,631 mm * | 1,271, 1,471 and 1,671 mm * | 1,311, 1,511 and 1,711 mm * | |

| Load per carrier | Max. 396.8 lbs | Max. 1,433 lbs | |

| Max. 180 kg | Max. 350 kg | Max. 650 kg | |

| Unit load (incl. carrier) | Max. 13,277.7 lbs | Max. 27,557.8 lbs | Max. 41,887.9 lbs |

| Max. 6,000 kg | Max. 12,500 kg | Max. 19,000 kg |

Kardex VCM Box

The box is perfectly adapted for the Vertical Carousel Module (VCM). Storage boxes can be adapted at any time by using cross and longitudinal dividers. The height of the Kardex VCM Box extends by using clip-on frames. The cross and longitudinal dividers are also available in different heights.

Software Solutions

The Kardex Power Pick System optimizes storage and retrieval in combination with Kardex machines. It covers multiple, smart picking strategies. By streamlining order fulfillment processes, it enhances productivity and ensures greater accuracy in high-demand warehouse environments.

.jpg)