When you're evaluating warehouse automation and vertical lift modules (VLMs), the question from leadership is always the same:

"How long until we see payback?"

To answer that question, you’ll need to know how automation will affect productivity, worker safety, and upkeep. Quantifying vertical lift module maintenance and labor cost savings is critical to determining the true return on investment.

The industry benchmark ROI for automated storage systems is about 18 months.

Yet, in a survey of 100+ Kardex Remstar customers, nearly 80% report achieving ROI in under a year.

- 33% saw ROI in 0–3 months

- 25.5% saw ROI in 3–6 months

- 20.8% saw ROI in 6–12 months

- 20.7% saw ROI in 12+ months

What's driving these faster returns?

In this post, we’ll show how Kardex Shuttle Vertical Lift Modules (VLMS) can deliver measurable value and why the numbers keep improving long after installation.

Understanding VLM ROI: What It Really Means for Warehouse Automation

Return on investment isn't just about recovering your initial spend. It's about transforming how your operation performs day after day. When you invest in a VLM, you're buying productivity gains, space optimization, and operational resilience that compound over time.

Think of VLMs as efficiency multipliers rather than one-time purchases. The value doesn't stop once you've paid off the system. It keeps delivering year after year.

To fully understand and quantify the potential ROI, your organization should analyze the current cost drivers of your warehousing and distribution operations and how the right automation can maximize cost savings.

>> Wondering how much a VLM costs? Our guide can help.

How to Calculate Vertical Lift Module (VLM) ROI

Using our Cost Justification Calculator for Automated Storage, you can begin to quantify ROI based on the specifics of your operations. Here are some things to consider:

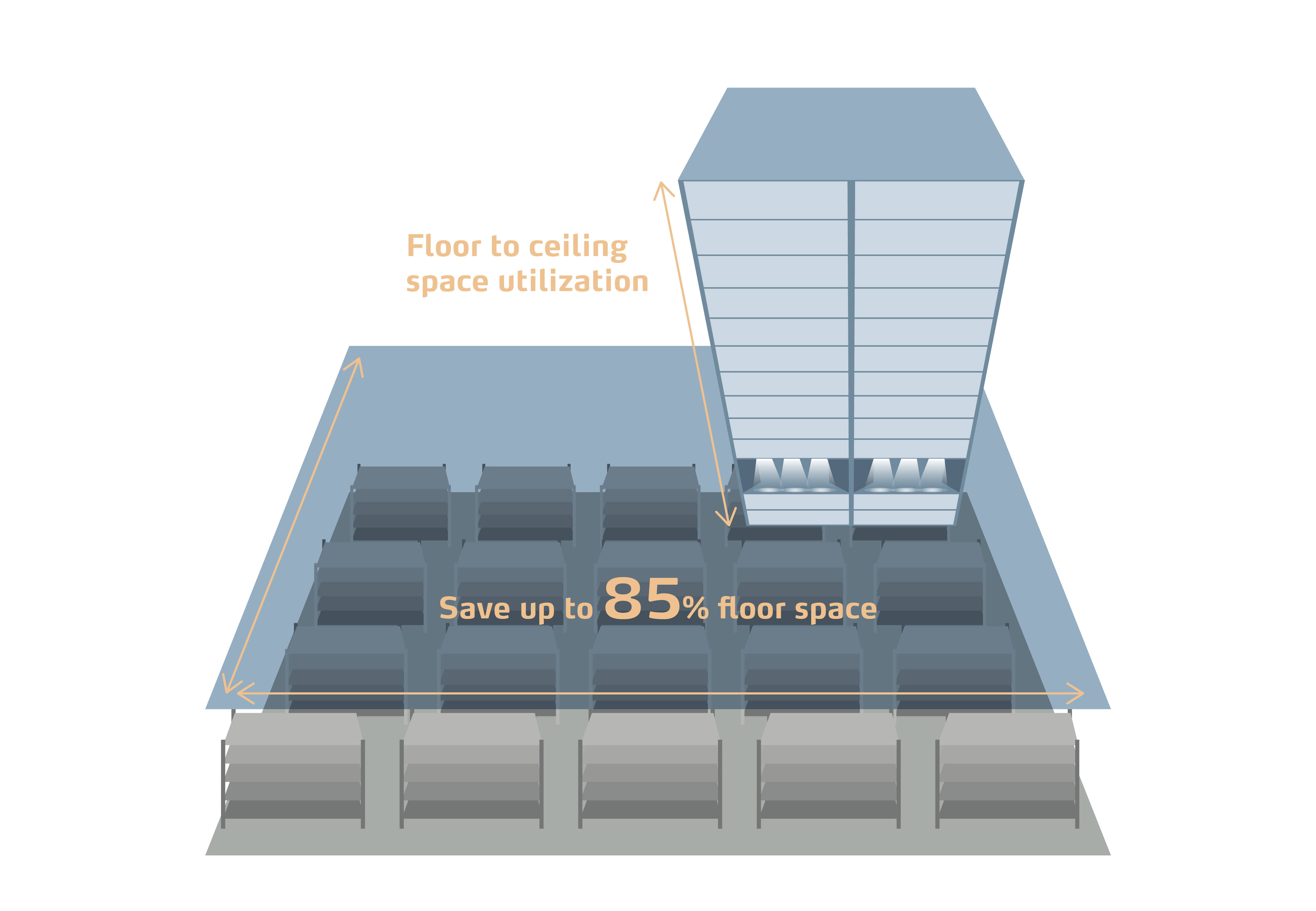

1. Floor Space Savings: More Space, More Value

In today's market, where warehouse space costs continue climbing, every square foot matters. Vertical lift modules can reclaim up to 85% of the floor space currently occupied by static shelving.

That's real square footage you can redirect toward production lines, packing stations, or additional storage capacity.

Want to see how VLMs could maximize your floor space?

Using the Kardex Cost Justification Calculator, you can enter your current warehouse's total floor space and see the potential cost per square foot savings from adding VLMs in real numbers.

2. Labor Savings: Do More With Fewer People

In a goods-to-person system, items come directly to an ergonomic work height, meaning less time spent walking aisles and climbing ladders. This type of warehouse automation has shown to improve pick efficiency by 200–300%.

In fact, 56% of Kardex customers report increased picking speed as one of their top benefits after installation. In a tight labor market, these gains mean your current team can handle significantly more volume without adding headcount.

“Labor is one of the biggest cost drivers in any warehouse,” notes Cal Bowers of Kardex. “VLMs let small teams perform like large ones.”

3. Pick Accuracy: Fewer Errors, Less Waste

Manual picking from traditional shelving creates opportunity for human error. With an automated VLM system, you get picking assistance built right in, including product tracking, barcode scanning, and guidance systems like pick-to-light technology, which can reduce picking errors by up to 99%.

Fewer mistakes mean fewer returns, less rework, and no emergency reshipments eating into your margins.

More importantly, it protects your customer relationships. In an era where one bad experience can lose you a client, accuracy is a competitive advantage.

4. Ergonomic Savings: Fewer Injuries, More Productivity

Overexertion involving handling objects accounts for nearly $14 billion in annual workplace injury costs, representing 23.5% of the most disabling injuries. Falls on the same level add another $11 billion. Traditional warehouse work requires climbing, reaching, repetitive bending, and moving heavy loads, which increase risk to worker injury.

Vertical lift modules can eliminate most of these hazards. Goods arrive at waist height. Fulfilling orders can be done without ladders, stretching, and repetitive strain from searching through aisles. The result is fewer workers' compensation claims, less downtime, and a healthier, more productive workforce.

5. Productivity Gains: Faster Throughput, Higher Revenue

Vertical lift modules and fulfillment automation not only increase speed, but they can also help your business grow. When your team can fulfill more orders in less time, you can take on additional business without expanding your footprint or workforce.

Plus, faster, more accurate delivery provides a higher level of service, which translates to happier customers and potentially higher margins on premium delivery options.

Regular vertical lift maintenance can further extend these productivity gains. Kardex systems are known for reliability and sustained uptime. Kardex offers on-site VLM maintenance services to maximize uptime and keep operations running smoothly.

6. Flexibility and Scalability: Investment That Grows With You

VLMs not only let you grow without expanding your footprint, but they also offer the flexibility and scalability companies need to ride fluctuations in businesses.

Working within your existing space, VLM systems can be expanded, reprogrammed, or even relocated as your operation evolves. This flexibility means your ROI continues growing over time rather than becoming obsolete as your business changes.

How to Achieve Faster ROI With the Right Vertical Lift Module

Maximizing ROI on a VLM system comes down to having a strong partner. Kardex helps customers understand their needs, develop solutions, and offer guidance from installation to regular vertical lift module maintenance.

“Automation isn’t one-size-fits-all,” explains Cal Bowers. “We help customers identify where the biggest savings will come from before they ever commit to a system.”

Here are some important factors that set Kardex Shuttle Vertical Lift Modules apart and help improve ROI:

- Proven design efficiency: Belt-driven mechanics and modular structures maximize uptime and minimize maintenance headaches. When vertical lift module maintenance is straightforward and infrequent, systems built to last don't nickel-and-dime you with constant repairs.

- Reliable performance: When equipment runs consistently, you capture the full value of your investment. Downtime is where ROI calculations fall apart. Kardex systems are engineered for continuous operation.

- Local service and support: A deep service network means VLM maintenance issues get resolved quickly. Your operation doesn't sit idle waiting for parts or technicians.

- Data-driven optimization: Tools like Kardex Connect and Kardex Analytics help you identify bottlenecks and continuously improve performance. The longer you operate the system, the smarter your operation becomes.

Do the Math: Using the Kardex ROI Calculator

When building a business case for capital investment, you need hard numbers.

That's where the Kardex Cost Justification Calculator comes in.

In about 10 minutes, you get realistic, site-specific ROI numbers based on your operation's actual conditions. Don't have all the data at your fingertips?

The calculator includes industry benchmarks to help you estimate. It's designed to give you concrete numbers and quantifiable projections you can use to make informed decisions and take to leadership.

The tool is designed to calculate how much VLMs and automation could save in your specific situation. It's the starting point for building an internal business case that stands up to scrutiny. From there, you can bring the data to a discussion with our team, who will discuss VLM costs based on your needs.

Beyond ROI: Long-Term Payoff and Lifecycle Value

Here's what makes VLM investment even more compelling: ROI continues to compound throughout the equipment's lifecycle.

Kardex Shuttle VLMs deliver longevity.

With continued software optimization through platforms like Kardex Connect, your system gets smarter over time, not obsolete. And with proactive vertical lift module maintenance and local support, you’ll keep downtime to a minimum year after year.

You're not just buying equipment. You're working with a company that's invested in your long-term success and is dedicated to serving as a partner every step of the way.

Fast ROI, Lasting Value

When nearly 80% of customers reach ROI in under a year and a third get there within three months, it's clear that VLMs deliver measurable, rapid returns. While these numbers are impressive, the real benefit of a VLM system is its sustained value: recovered space, improved productivity, enhanced safety, and operational flexibility that grows with your business.

A Kardex system doesn't just deliver fast return. It offers lasting results. From space and labor savings to long-term reliability, the case for automation is stronger than ever.

Ready to see what automated VLMs could save you? Try the Kardex Cost Justification Calculator.