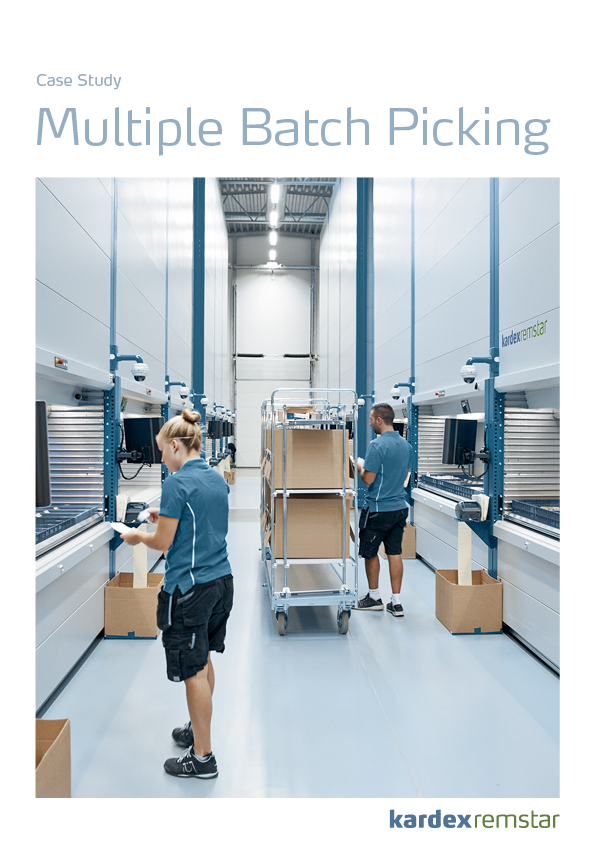

Automated Order Fulfilment for E-Commerce & Retail

Enhance your order fulfilment processes with Kardex' automated storage and retrieval systems (ASRS). Increase speed, improve accuracy, and exceed customer expectations while reducing labour costs.

In the e-commerce and retail industries, speed of order fulfilment, accuracy, and warehouse efficiency are paramount. Ever-increasing customer expectations challenge managers to manage growing order volumes, complex inventory, and next-day delivery expectations.

Kardex offers scalable and flexible ASRS solutions designed to optimise storage, picking, packing, and shipping processes along with inventory management. With our extensive experience in developing automated solutions for e-commerce and retail companies, we can help you improve order fulfilment speed and accuracy, overcome labour shortages, and maximise warehouse space.

Features & Benefits

-

Faster Order Delivery

Automate order fulfilment and significantly reduce delivery time

-

99.9% Picking Accuracy

Minimise errors in picking and reduce order returns

-

Boosted Labour Efficiency

Pick more orders with fewer staff, addressing labour shortages

-

Real-Time Inventory Control

Gain transparency and control with real-time inventory tracking

-

Optimised Warehouse Space

Recover up to 85% floor space with maximised storage capacity

-

Easy Scalability

Adapt and grow your system as your business expands

Faster Order Delivery

Automate order fulfilment and significantly reduce delivery time

99.9% Picking Accuracy

Minimise errors in picking and reduce order returns

Boosted Labour Efficiency

Pick more orders with fewer staff, addressing labour shortages

Real-Time Inventory Control

Gain transparency and control with real-time inventory tracking

Optimised Warehouse Space

Recover up to 85% floor space with maximised storage capacity

Easy Scalability

Adapt and grow your system as your business expands

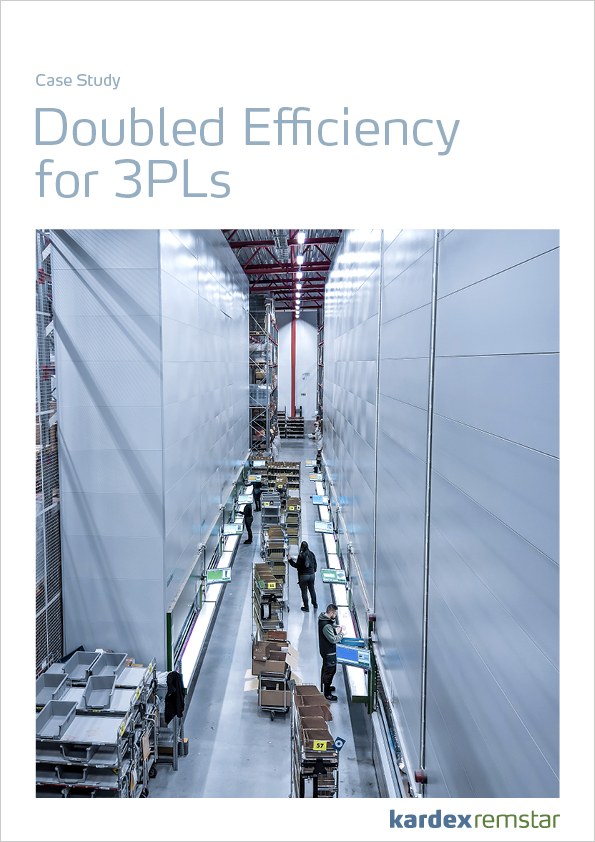

Customer Success Stories

Automating order fulfilment for e-commerce & retail success

Solutions for E-Commerce & Retail

What is your most important goal for an optimised order fulfilment process? Discover what Kardex products, systems, and services can help you achieve it.

Increase Picking Speed

The Kardex Miniload-in-a-Box, Kardex Shuttle and AutoStore™ system, deliver small to medium-order items directly to the picker. Eliminating the need to walk from aisle to aisle. While an operator picks an item, the next item is cued in the machine. This eliminates dwell time and increases throughput. The Kardex Shuttle offers higher storage density, but searches are typically faster with the tote-based Kardex Miniload-in-a-Box. Whereas AutoStore stands out with its high-speed robotic picking and compact cube storage.

Enhance Picking Accuracy up to 99.9%

Our automated solutions minimise picking errors ensuring that the right product is practically always selected. Pick-to-light technology and other assistive tools (e.g., Wearable Task Assistant, Intuitive Picking Assistant) or picking strategies (e.g., Kardex Color Pick System) guide the operators to the right items, ensuring consistent fulfilment accuracy. This not only minimises costly errors, but also improves customer satisfaction by ensuring the right items are delivered on time.

Increase Employee Efficiency by 300%

Kardex solutions reduce the need for manual picking, allowing your existing workforce to focus on higher-value tasks increasing productivity and operational efficiency.

Recover up to 85% Floor Space

The Kardex Shuttle, Kardex Miniload-in-a-Box and AutoStore maximise the use of vertical warehouse space, reducing your overall footprint. This allows you to store more products and future-proof your business without needing to expand your physical warehouse space.

Improve Inventory Management

Streamline your inventory control with Kardex' integrated software solutions. Our systems provide real-time data and analytics, giving you comprehensive insights into inventory levels, usage patterns, and system performance. This actionable data helps you make informed decisions, optimise stock levels, and improve overall warehouse management.

More Solutions from Kardex

Cube Storage

Can you imagine handling four times the number of SKUs within your current warehouse without changing your facility size or shape? Now imagine having the fastest order fulfilment system per square foot on the market. Sounds like a pretty amazing idea, right?

As a global AutoStore partner, Kardex offers a high-performance, space-saving storage and picking solution for small parts. Applicable across multiple industries and able to handle any kind of small parts, high-speed robots from AutoStore are redefining warehouse operations.

Kardex Miniload-in-a-Box

Is order consolidation on your agenda? Implementing an automated consolidation buffer to manage your order consolidation process can help your warehouse or distribution centre increase productivity, save space, support packaging, and reduce shipping bottlenecks. With the Kardex Miniload-in-a-Box, you can easily configure a system to operate as a semi- or fully automated process.

How to Achieve Fast Order Fulfilment

Learn how automating your warehouse can boost productivity by up to 400%. Explore key strategies to streamline operations and keep pace with rising customer expectations in retail and wholesale.