Kardex Megamat

The Kardex Megamat, also known as a Vertical Carousel Module (VCM), is perfectly suited for goods with a high picking frequency and uniform sized inventory.

Using the paternoster principle the Kardex Megamat provides quick and precise access to stored goods. It is especially suitable for frequently accessed goods because it conveys the needed carrier to the access opening via the shortest possible path.

Features & Benefits

-

Fast Picking

Fast access to all stored goods and high picking performance.

-

Accurate Picking

Optional tools to increase accuracy rates.

-

Minimal Footprint

Enables organised storage locations and space savings of up to 85%.

-

Ergonomic Workspace

Smooth and smart design for ergonomic access.

-

Modular & Scalable Design

Modular and scalable hardware and software to fit individal needs

-

Intuitive Interface

Future oriented system based on the latest technologies.

Fast Picking

Fast access to all stored goods and high picking performance.

Accurate Picking

Optional tools to increase accuracy rates.

Minimal Footprint

Enables organised storage locations and space savings of up to 85%.

Ergonomic Workspace

Smooth and smart design for ergonomic access.

Modular & Scalable Design

Modular and scalable hardware and software to fit individal needs

Intuitive Interface

Future oriented system based on the latest technologies.

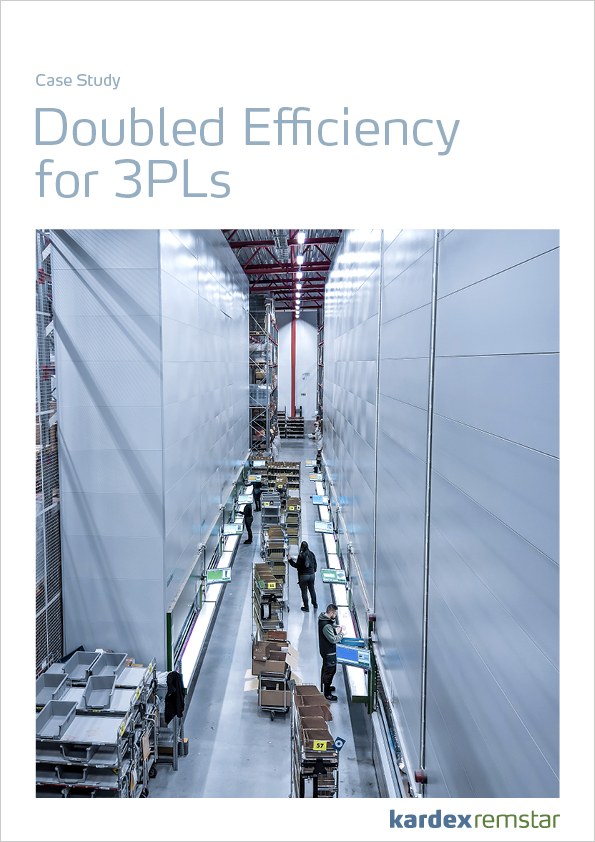

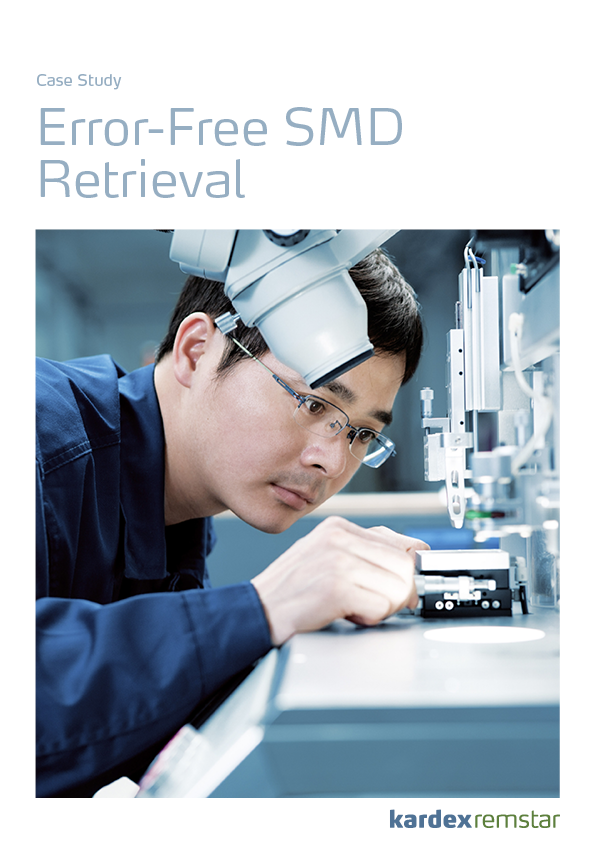

Customer Success Stories

How does the Kardex Megamat work?

Paternoster System for Automated Storage

The Kardex Megamat is a smart warehouse technology designed to optimise order picking, spare parts management, and SMD handling. It ensures quick access to all goods by conveying the right carrier to the access opening via the shortest possible path. It is the ideal choice when storing products with similar heights.

Kardex tailors solutions to meet various industry needs by offering a variety of Kardex Megamat machines (Kardex Megamat 180, 350 & 650). Whether warehouse requirements call for picking small, lightweight parts, storing and retrieving loads up to 650 kilograms, using as an interim storage solution for semi-finish products or as a storage buffer during drying phases, Kardex offers multiple options.

It offers a range of options so that users can benefit from higher performance results and see improvements in throughput, accuracy and lifetime.

The Kardex Megamat carriers provide efficient, orderly storage. Optimised for different processes, they can be adapted to individual business requirements. Intermediate shelves allow you to subdivide the carriers. Any combination of drawers and dividers can be used. Storage space of up to 16 square metres per carrier is possible.

Technical Data

| Kardex Megamat 180 | Kardex Megamat 350 | Kardex Megamat 650 | |

|---|---|---|---|

| Width | 1,875 to 3,875 mm | 1,875 to 4,275 mm | 1,975 to 4,275 mm |

| Height | 2,210 to 7,510 mm | 2,360 to 10,010 mm | 2,360 to 10,010 mm |

| Depth | 1,251 mm, 1,441 mm, and 1,631 mm * | 1,271 mm, 1,471 mm, and 1,671 mm * | 1,311 mm, 1,511 mm, and 1,711 mm * |

| Load per carrier | Max. 180 kg | Max. 350 kg | Max. 650 kg |

| Unit load (incl. carrier) | Max. 6,000 kg | Max. 12,500 kg | Max. 19,000 kg |

More Solutions from Kardex

Kardex Shuttle

A high-density automated storage and retrieval system that maximises storage capacity while optimising picking and retrieval processes. It is suitable for a wide range of industries and products of various dimensions. The Kardex Shuttle can be integrated with other Kardex solutions.

Kardex VCM Box

The Kardex VCM Box is a modular storage box with a divider system. The boxes are tailor-made for the Vertical Carousel Module (VCM) and provide flexible, customised, and organised storage locations. They can be adapted at any time by using cross and longitudinal dividers. The height of the Kardex VCM Box extends by using clip-on frames.