Kardex Miniload-in-a-Box

The Kardex Miniload-in-a-Box, also known as the Vertical Buffer Module (VBM), is a high density storage solution suitable for small warehouses.

The Kardex Miniload-in-a-Box is an efficient solution for fast-growing product ranges with limited space. It works as a miniload system and flexibly stores, picks, and buffers small parts. Miniloads offer valuable benefits by maximising space utilisation at minimal costs.

Features & Benefits

-

Order Consolidation

Automated order consolidation capabilities

-

Flexible & Scalable

Flexible and scalable design to fit individual needs

-

Modular

Modular up to 20 metres in length and 12 metres high

-

Carrying Capacity

Capable of handling items weighing up to 35 kg

-

Box Handling

Automatic box handling with conveyors

-

Item Picking

Discrete item picking for increased inventory control

Order Consolidation

Automated order consolidation capabilities

Flexible & Scalable

Flexible and scalable design to fit individual needs

Modular

Modular up to 20 metres in length and 12 metres high

Carrying Capacity

Capable of handling items weighing up to 35 kg

Box Handling

Automatic box handling with conveyors

Item Picking

Discrete item picking for increased inventory control

Customer Success Stories

How does the Kardex Miniload-in-a-Box work?

Pick Small Parts Quickly and Efficiently with the Kardex Miniload-in-a-Box

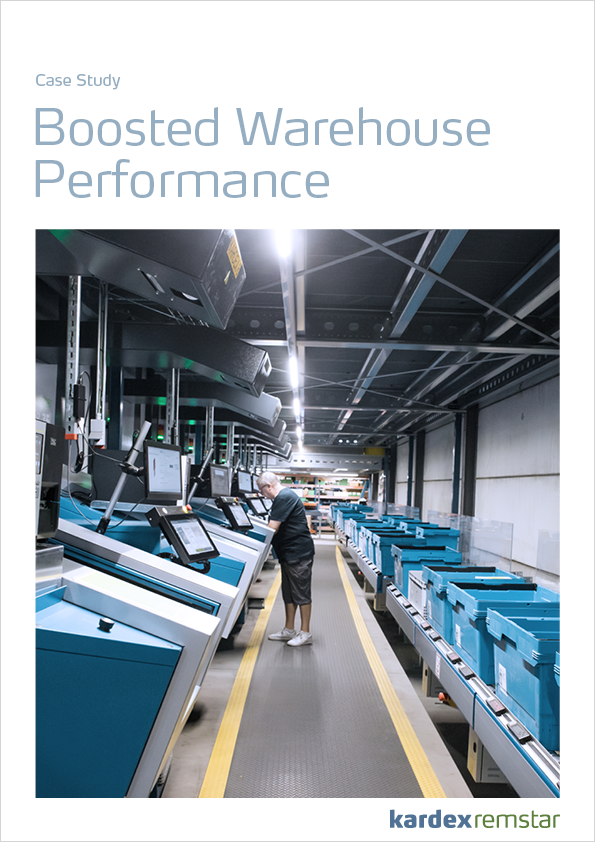

The Kardex Miniload-in-a-Box is a market leading solution for improving the order picking efficiency of small or lightweight items. This sophisticated technology can be utilised in various scenarios such as replenishing a diverse product line, serving as a buffer storage in the assembly area, or facilitating the selection of infrequently requested parts in a distribution warehouse. Delivering a notable uptick in productivity along with enhanced accuracy and energy efficiency.

Providing a flexible and scalable approach, this system allows a workstation to be composed of a single unit, or multiple units aggregated as required. This grants companies an opportunity to attain maximum storage capacity and performance. Further adding to its adaptability, it provides a range of options for the access opening and permits unit size customisation up to 20 metres in length and 12 metres in height, making it a versatile solution for many applications. Moreover, it seamlessly integrates into existing processes and syncs effortlessly with various customer host-systems.

In an era where the significance of ergonomic picking is becoming prominent, the Kardex Miniload-in-a-Box offers customers ergonomic workstations that simplify the picking process and enhance overall working conditions. Featuring a 20-degree tilt at each access opening and the efficient goods-to-person principle, it delivers items straight to the operator, eliminating unnecessary movement and search time.

Technical Data

| Performance | High order picking performance based on bin cycles and number of order lines. Max. total load 63 metric tons |

|---|---|

| Bins | Standard mini-load system compatible bins 600 x 400 mm (up to 640 x 440 mm). Load 35 kg | bin. Individually designed Kardex VBM Boxes (640 x 440 x 140 mm) are available |

| Width | 1.920 to 19.970 mm |

| Depth | 2.350 mm |

| Height | 3.000 to 12.000 mm (in 100 mm steps) |

| Unit vertical steps | 100 mm steps |

More Solutions from Kardex

Kardex Shuttle

A high-density automated storage and retrieval system that maximises storage capacity while optimising picking and retrieval processes. It is suitable for a wide range of industries and can be integrated with other Kardex solutions.

Kardex VBM Box Accessory

The Kardex VBM Box is a storage and transport box that includes a flexible divider system. With dimensions 640 x 440 x 140 mm, the box is perfect for the Kardex Miniload-in-a-Box. Storage boxes can be divided or adapted at any time using transverse and longitudinal dividers for increased flexibility. The height extends in a 50 mm grid using push-on frames.