Bin Conveyor Systems

Kardex offers bin conveyor systems as part of larger automated warehouse solutions. These conveyors help boost material flow, reduce manual bin handling, and optimise labour resources.

Bin conveyor systems transport all types of bins, cartons, and trays, adapting to your individual requirements to guarantee optimum performance and efficiency. Our portfolio includes both horizontal and vertical conveyor products, which perform multiple functions, including conveying, sorting, storing, and accumulating. These conveyors complement small parts solutions such as our miniload systems, the bin shuttle system, or the AutoStore system.

Features & Benefits

-

Improved Material Flow

Ensure seamless movement of goods with reliable conveyor systems

-

Reduced Manual Handling

Minimise labour-intensive tasks and streamline processes with automation

-

Increased Productivity

Accelerate packing and shipping operations with fast, reliable conveyors

-

Flexible Load Capacity

Easily transport bins, cartons, and trays of varying sizes and weights

-

Space Optimisation

Maximise your storage space with horizontal and vertical conveyor options

-

Scalable Solutions

Adapt your conveyor setup to growing warehouse demands and changing workflows

Improved Material Flow

Ensure seamless movement of goods with reliable conveyor systems

Reduced Manual Handling

Minimise labour-intensive tasks and streamline processes with automation

Increased Productivity

Accelerate packing and shipping operations with fast, reliable conveyors

Flexible Load Capacity

Easily transport bins, cartons, and trays of varying sizes and weights

Space Optimisation

Maximise your storage space with horizontal and vertical conveyor options

Scalable Solutions

Adapt your conveyor setup to growing warehouse demands and changing workflows

Insights and Customer Success Stories

Bin Conveyors in Action

Custom-Built Solutions with Bin Conveyors

At Kardex, Bin conveyors are always part of a larger ASRS solution that is designed and customised to meet the specific needs of your facility and processes. Here’s how they can play an essential role in transforming your warehouse operations:

Maximised Material Flow

Bin conveyors ensure automated, efficient movement of goods throughout your warehouse. Integrated with small parts solutions such as our miniload system, bin shuttles or AutoStore system, they facilitate rapid transport between storage and picking areas, improving throughput and reducing bottlenecks.

Optimised Workforce Efficiency

Bin conveyors minimise manual handling, allowing your team to focus on high-value tasks. Ergonomic picking stations further enhance productivity by reducing physical strain on workers.

Enhanced Picking Accuracy

Combined with Kardex goods-to-person systems, bin conveyors deliver items directly to operators, significantly reducing the need to walk, search for, and carry goods in the warehouse.

Scalability for Growth

As your inventory grows, additional conveyor lines or storage units can be added to accommodate increased capacity, ensuring smooth operations without disrupting current processes.

More Solutions from Kardex

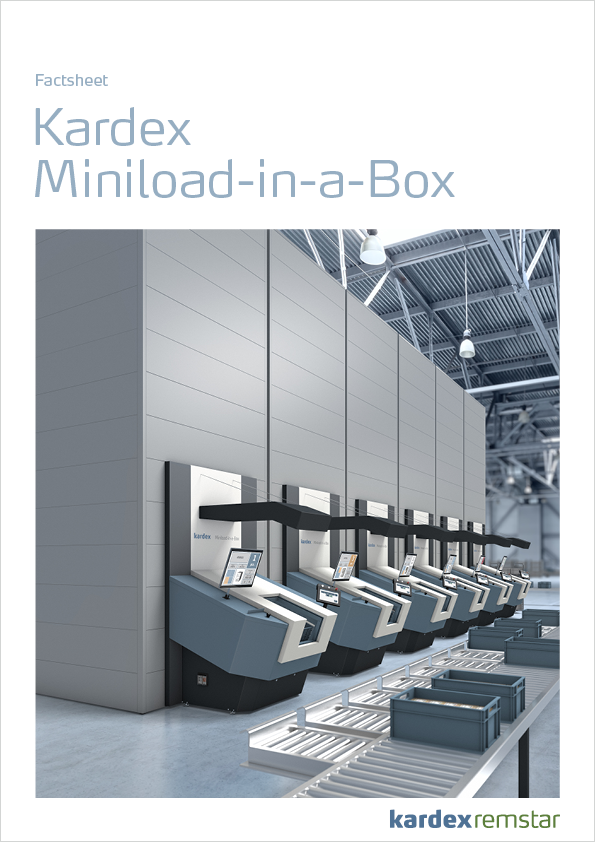

The Kardex Miniload-in-a-Box

The Miniload-in-a-Box is designed for businesses with growing product ranges and limited storage space. Ideal for handling small parts and lightweight goods, this system delivers high-speed, accurate order picking and compact storage.

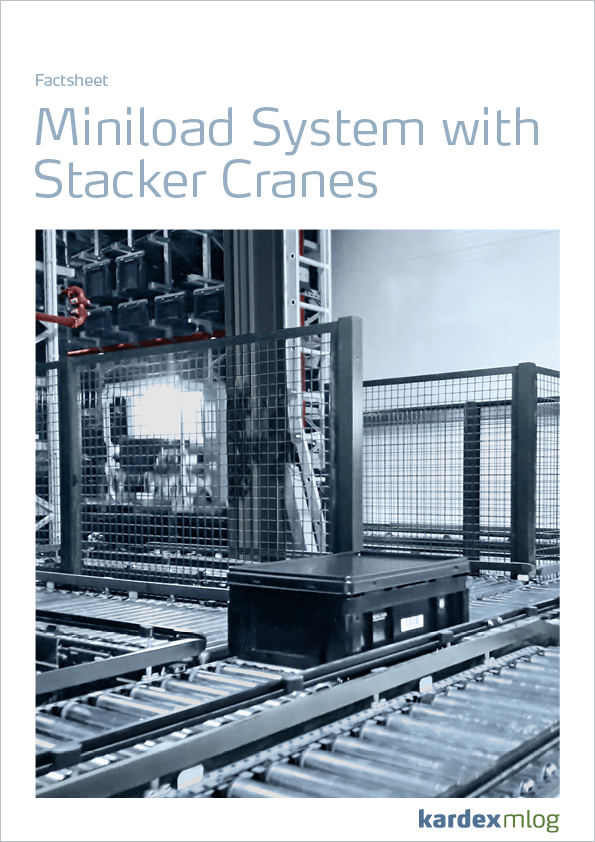

Miniload System

The miniload system is a tailor-made solution with a height of up to 24 metres. It offers the possibility of single- or multi-deep storage and manages various load-handling devices.

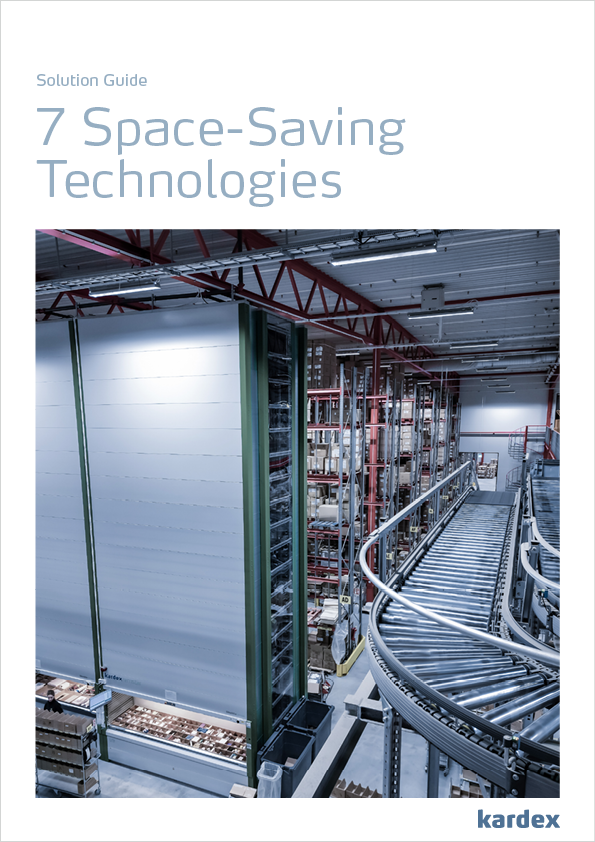

7 Space-Saving Technologies

Different storage systems can be customised for various storage needs, from small, lightweight goods to medium-sized to heavy-duty materials and pallets. This solution guide presents 7 technologies you should consider when space is an issue.