Automation for Automotive and Transportation Industry

Automotive parts production and handling require precise material flow, efficient management of product variants, and reliable support for just-in-time delivery. Kardex automated solutions provide a flexible foundation for production, distribution, and fulfillment with accurate inventory control and fast access to parts.

From just-in-sequence production supply and support in vehicle assembly to service and aftermarket fulfillment, Kardex solutions adapt to different operating models helping organizations improve efficiency, reduce costs, and scale as demand changes.

Features & Benefits

-

Just-in-Time

Ensure materials arrive exactly when needed in the production flow, minimizing delays and bottlenecks

-

Just-in-Sequence

Deliver parts in the exact order needed, ensuring seamless assembly operations

-

Inventory Management

Always know the exact location, status, and readiness of your inventory with real-time tracking

-

Optimized Space Usage

Maximize storage efficiency with compact, high-density solutions

-

Safe Materials Handling

Prevent unauthorized access and materials damage with secure storage solutions

-

Reduced Downtime

Minimize repair times and keep operations running smoothly with efficient parts management

Just-in-Time

Ensure materials arrive exactly when needed in the production flow, minimizing delays and bottlenecks

Just-in-Sequence

Deliver parts in the exact order needed, ensuring seamless assembly operations

Inventory Management

Always know the exact location, status, and readiness of your inventory with real-time tracking

Optimized Space Usage

Maximize storage efficiency with compact, high-density solutions

Safe Materials Handling

Prevent unauthorized access and materials damage with secure storage solutions

Reduced Downtime

Minimize repair times and keep operations running smoothly with efficient parts management

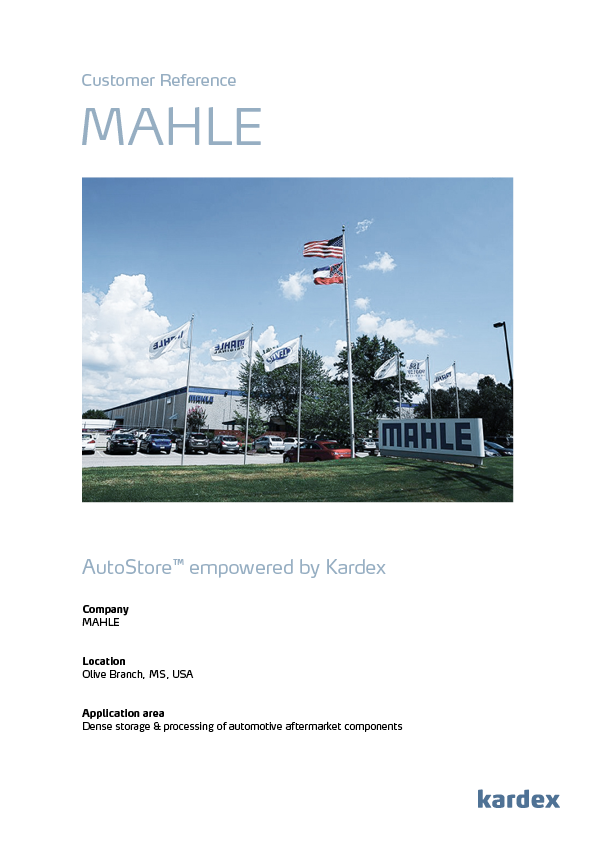

Customer Success Stories

Custom-Built Solutions to Fit Your Needs

Kardex offers a suite of products and systems to meet the diverse material flow challenges of the automotive and transportation industries.

Manufacturing: Need Storage for Pallets, Small Parts, or a Combination?

Efficient material flow is essential for automotive manufacturers, especially when handling palletized goods, small components, or a mix of both.

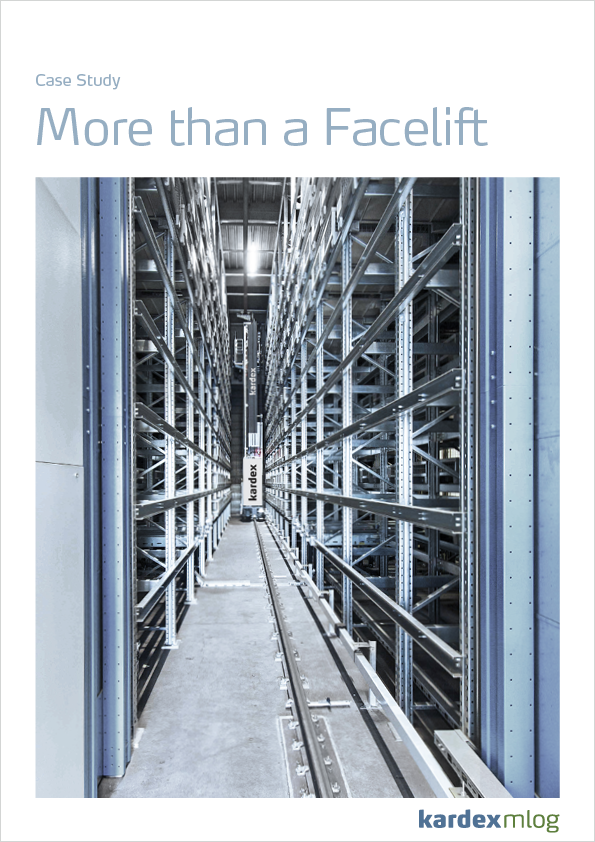

Storing palletized goods and large components

For palletized goods and large components, our high-bay warehouse is the best solution. It offers the option of single or multiple-depth storage, can serve as a production buffer, and ensures a smooth flow of materials between production and dispatch. It also integrates seamlessly with your ERP and WMS systems for full inventory control.

Storing small and medium-sized parts

For small and medium-sized parts, Kardex offers a range of flexible solutions:

- Our Miniload Systems support high-throughput storage of small load carriers.

- The AutoStoreTM system represents an ultra-dense storage solution with fast, reliable picking powered by robots.

- The Vertical Buffer Module Kardex Miniload-in-a-Box enables fast, space-saving bin retrieval.

- The Vertical Lift Module Kardex Shuttle handles items of varying sizes and is ideal for mixed inventory.

All Kardex systems can be combined with conveyors, AGVs, and warehouse software to create a tailored, fully automated material flow solution or work in semi-automated setups.

All of these systems are highly efficient, but the right choice depends on several factors such as your building height, storage volume, item sizes, and how materials flow through your facility.

That is why we work closely with you to design a solution that fits your exact needs. Whether you are handling pallets, bins, or both, we can help you identify the ideal setup to optimize your space, speed, and efficiency.

Assembly: Need Just-in-Sequence Part Delivery?

Automotive assembly lines demand absolute precision. Every component must arrive at the right time, in the right order, and with zero errors. Kardex offers a broad portfolio of solutions to solve this, each with its own strength.

- The VLM Kardex Shuttle, equipped with pick-to-light technology, is ideal for just-in-sequence picking. It ensures parts are delivered in the correct order for streamlined installation.

- The VBM Miniload-in-a-Box supports high-speed bin retrieval for space-constrained areas and rapidly changing component needs.

- The AutoStore with Intuitive Picking Assistant (IPA) enables highly accurate, just-in-sequence picking for small parts. Visual pick guidance, item images, and precise bin highlighting reduce picking errors and downtime while supporting consistent line-side supply.

- Buffer Storage Systems for pallets and large parts can be used between production and assembly. These solutions ensure materials are pre-sequenced and ready for just-in-time delivery, keeping your line running without interruptions.

In maintenance, repair, and overhaul (MRO), every minute counts. Delays in spare parts access can halt production and increase costs.

- The VLM Kardex Shuttle provides ergonomic, on-demand access to high-use parts.

- The VBM Miniload-in-a-Box enables compact storage and fast retrieval of small spares and consumables.

- The AutoStore with zero single point of failure ensures traceable spare-part storage and brings the right bin to the worker, reducing errors and response time.

- For large or irregular spare parts, Kardex Mlog high-bay warehouses offer secure, fully traceable storage integrated with the Kardex Control Center for centralized visibility and control.

More Solutions from Kardex

Efficient Buffering & Sequencing

Efficiently store automotive parts that require preparation or value-added processes (e.g., painting, kitting, light assembly) until needed. Buffer storage provides clean, organized storage and ensures parts are readily available for just-in-time production or order fulfillment.

Orders ready to ship are packed in cartons or on pallets and transported individually to the storage system, where they are automatically scanned, stored, and managed until required for domestic or international distribution.

ASRS Software Solutions

Certified Interface for Automotive Dealerships

The Kardex Power Pick System maintains a CDK Global certified interface to support automotive dealerships using select Kardex automated storage and retrieval systems. Discover more here.