Kardex FulfillX Software Highly configurable software to optimize AutoStore robots, operators, inventory accuracy and flexibility.

Simplify the operator experience and optimize AutoStore™ performance with Kardex FulfillX, the only purpose-built AutoStore software that extends your WMS without modification.

Kardex FulfillX is a purpose-built AutoStore software solution designed to optimize warehouse execution and streamline operations. As a dedicated warehouse execution system (WES), Kardex FulfillX enhances the performance of AutoStore by maximizing robot utilization, improving operator workflows, increasing inventory accuracy, and providing flexibility to adapt to changing warehouse demands.

Features & Benefits

-

Modern Architecture

A web client interface with flexible integration protocols ensures compatibility with existing systems and facilitates easy adoption

-

Optimized Tasking

Kardex FulfillX minimizes the number of AutoStore robots, optimizing performance and reducing costs by up to 20%

-

Intuitive Picking Assistant

The software seamlessly integrates with the Kardex's Intuitive Picking Assistant, enhancing efficiency and accuracy

-

Multilingual Support

Kardex FulfillX supports over 100 languages, allowing operators to work in their preferred language

-

Operator Efficiency

Real-time bin configuration, in-line cycle count, and order expediting capabilities improve operational efficiency

-

Flexible Integration

Versatile integration with external technologies, facilitating collaboration and interoperability in complex software ecosystems.

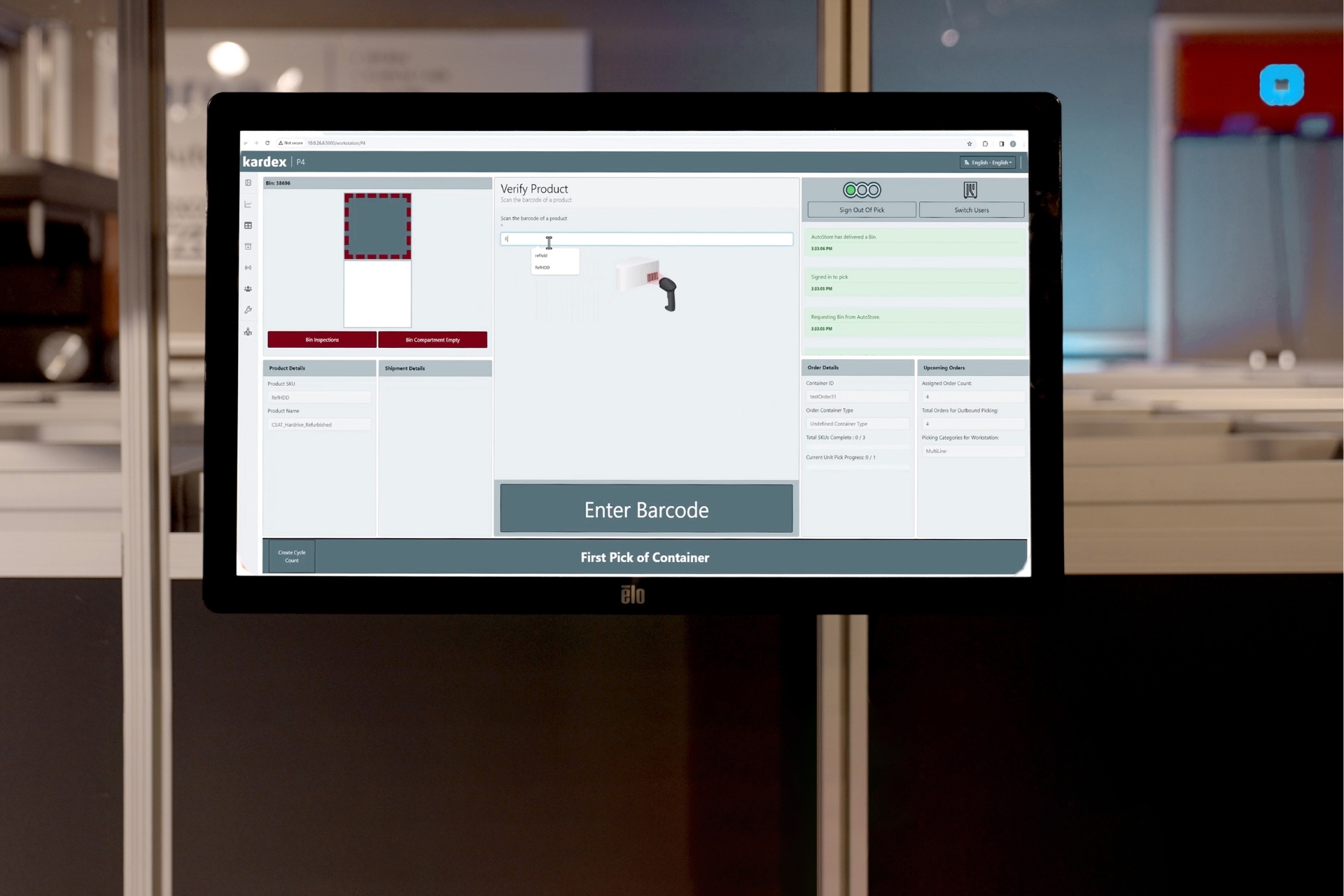

Modern Architecture

A web client interface with flexible integration protocols ensures compatibility with existing systems and facilitates easy adoption

Optimized Tasking

Kardex FulfillX minimizes the number of AutoStore robots, optimizing performance and reducing costs by up to 20%

Intuitive Picking Assistant

The software seamlessly integrates with the Kardex's Intuitive Picking Assistant, enhancing efficiency and accuracy

Multilingual Support

Kardex FulfillX supports over 100 languages, allowing operators to work in their preferred language

Operator Efficiency

Real-time bin configuration, in-line cycle count, and order expediting capabilities improve operational efficiency

Flexible Integration

Versatile integration with external technologies, facilitating collaboration and interoperability in complex software ecosystems.

Helpful Resources

Kardex FulfillX — Purpose-Built Software for AutoStore

Highly configurable AutoStore software designed to optimize AutoStore robots, operator performance, inventory accuracy, and flexibility to meet your needs.

Accelerate deployment with FulfillX integration capabilities that are compatible with existing WMS protocols, including FTP, SFTP, RESTful, HTTP, HTTPs, TCP/IP, flat files, and more.

Maximize operator efficiency with the adaptable Kardex FulfillX software that matches your common practices. Supporting over 100 languages and features like in-line cycle count confirmation, order expediting, and adjustable bin configurations, Kardex FulfillX provides the flexibility to tailor the solution to your specific needs.

Future flexibility is built in with robust endpoints and configurations that enable rapid adjustments. Whether extending AutoStore with robotic bin picking or integrating packaging automation to reduce shipping costs, Kardex FulfillX is ready for you.

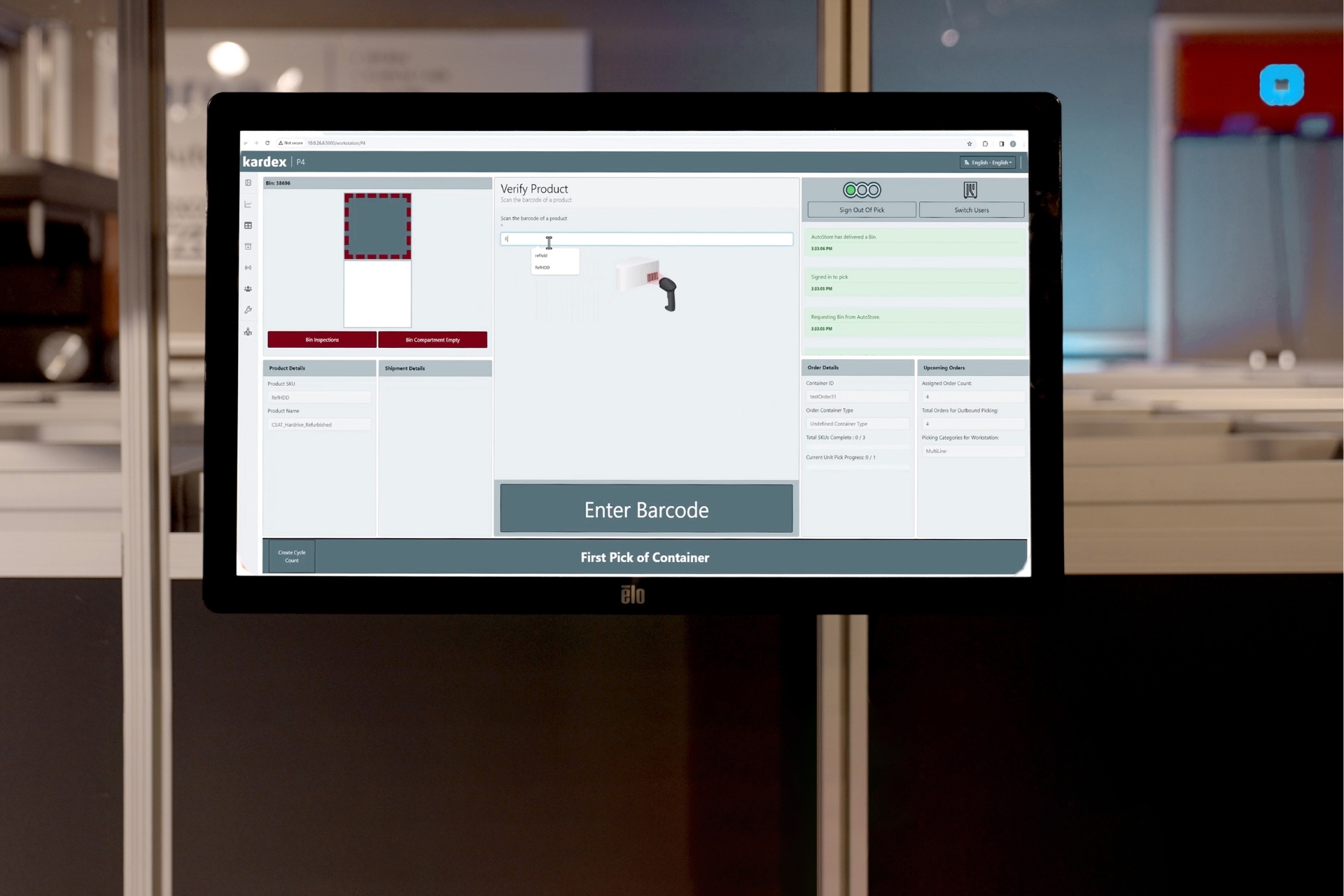

How does Kardex FulfillX work?

Flexible Software for Your AutoStore Workflows

The Kardex FulfillX Project Team works closely with your operations and IT teams to outline and configure your initial deployment to align wih your business needs.

Replenishment/Goods In

Replenishment involves manually placing goods into the AutoStore bins. FulfillX WES guides users to ensure the highest level of accuracy.

Picking/Goods Out

FulfillX WES provides guidance for specific processes, such as in-line scanning and serial number capture, to efficiently complete customer orders.

Real-Time Bin Configuration

Flexibility is a paramount feature of FulfillX. Users can adjust the bin configuration to multiple locations (2x1, 4x1, 8x1, etc.) or a single location (1x1) directly at the port.

Intuitive Picking Assistant

The Intuitive Picking Assistant (IPA) is the next generation solution for warehouse operations at the AutoStore Ports. Using projection and 3D vision systems, IPA enhances efficiency and performance.

More AutoStore Solutions by Kardex

Intuitive Picking Assistant

The Intuitive Picking Assistant elevates picking processes of AutoStore™ Solutions to the next level. By projecting all relevant picking information, it guides the operator through the picking process.

This integration offers a scalable solution to meet the evolving needs of warehouses, optimizing efficiency and accuracy in picking processes, and addressing the challenge of finding highly trained workers.

CarouselAI

CarouselAI, an advanced robotic picking technology, handles a wide range of SKUs using its adaptive gripper technology.

- 650 units/hour with 24/7 consistency—no breaks, no overtime

- Seamless integration with AutoStore via Kardex’s FulfillX software

- Proven in the real world—Kardex is the only integrator to deploy CarouselAI on a live customer site

.jpg)