Operational Consulting

The efficiency and performance of a storage solution depends on many different factors including implemented processes and technologies. In order to ensure the best overall performance of a system throughout its entire life cycle, it should be put to the test over and over again.

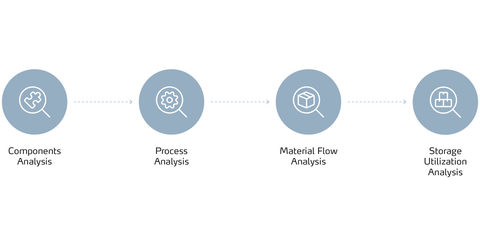

Hand in hand with you, the Kardex Life Cycle Service team will analyze your installed components, processes, material flow, and warehouse utilization regularly. Our recommendations will ensure your systems are optimized and always up to date.

Kardex experts take preventive measures before operations get impacted and identify ways to continuously improve and maximize performance. We also keep you informed about new products and the latest technology!

Success stories

Tab Navigation

Replacing Existing Shelving

Jazz Aviation turned to Kardex to address severe space limitations at their airport-adjacent facility. With inventory spread across cramped areas, locating parts was time-consuming and inefficient, creating bottlenecks in their supply chain.

Kardex provided a comprehensive solution that consolidated bulk inventory that had overflowed into the airport hanger into a centralized stockroom within the warehouse, improving inventory control and accessibility. The shift not only saved space but also streamlined operations and reduced labor-intensive tasks.

“Space is a premium being next to an airport,” said Mike Hauser, Stores System Manager, “It was a constant battle, we had no more room. We needed a full supply chain solution, not just a temporary fix.”

Long Term Partnerships

Körber partnered with Kardex to solve space constraints caused by increasing part volumes. Instead of simply delivering equipment, Kardex provided a complete, customized solution starting with a cube analysis to optimize space and efficiency.

The project included not just equipment installation, but a logical parts slotting plan and physical parts loading. Kardex worked closely with Körber to ensure a smooth transition and minimal disruption to operations.

“We needed a complete solution start to finish; from the initial cube analysis and equipment installation to providing a logical parts slotting plan and physical parts loading through long term support – and that’s what we got,” said Austin Williams, Stockroom Manager at Körber.

.jpg)