Optimizing Small Parts Storage

Storing, managing, and picking single items such as small and lightweight goods requires a solution that optimizes picking performance. Our automated systems efficiently store, retrieve, and pick small items with speed and accuracy, reducing errors and increasing productivity.

Kardex systems optimize the storage of small and light goods, increase productivity, reduce energy consumption and minimize error rates. Our solutions provide easy-to-use material flow control and warehouse management tailored to meet different operational needs. Use them for high-bay storage, supplying production lines, picking slow-moving parts in distribution centers, or as buffer storage in assembly areas. Easily customizable, Kardex solutions adapt to your specific needs, ensuring efficient and flexible small parts management across industries.

Features & Benefits

-

High Picking Performance

Accelerate order processing to meet high customer demand

-

Increased Accuracy

Reduce errors with precise picking and inventory management

-

Optimized Use of Space

Maximize storage capacity through vertical space utilization

-

Increased Efficiency

Reduce operator walking distances and search times

-

Improved Ergonomics

Increase satisfaction by delivering items directly to the operator

-

Customizable Solutions

Expand operations smoothly as demand grows

High Picking Performance

Accelerate order processing to meet high customer demand

Increased Accuracy

Reduce errors with precise picking and inventory management

Optimized Use of Space

Maximize storage capacity through vertical space utilization

Increased Efficiency

Reduce operator walking distances and search times

Improved Ergonomics

Increase satisfaction by delivering items directly to the operator

Customizable Solutions

Expand operations smoothly as demand grows

Customer Success Stories

Efficient Small Parts Handling at Van Meter

Ready to Improve Small Parts Picking Efficiency?

Get a practical introduction to ASRS for smarter small parts storage and handling that can optimize space, speed up fulfillment, and reduce picking errors

Optimize Small Parts Picking with Kardex Solutions

Kardex helps organizations transform how they handle small parts picking—improving efficiency, accuracy, and space utilization across every step of the process. Whether you're managing spare parts, components, or high-volume SKUs, our solutions are designed to streamline workflows and drive measurable results.

Increase Efficiency and Save Space

Kardex solutions are built to support high-density storage and fast retrieval of small and lightweight goods. By maximizing vertical space and reducing walking time, our systems can help you recover up to 85% of floor space, making them ideal for warehouses with limited capacity or growing inventory needs.

Boost Accuracy and Throughput

Small parts picking requires precision. Kardex solutions are designed to minimize handling errors and improve fulfillment speed—delivering picking accuracy rates up to 99.9%. With intelligent workflows and guided picking, your team can maintain high productivity while ensuring the right items are delivered on time, every time.

Tailored to Your Operation

No two operations are the same. Kardex systems are fully customizable to fit your specific storage and picking requirements. From bin sizes and shelving configurations to adaptable layouts that scale with your product range, we help you build the right setup for your workflow.

Organize Better with Smart Storage Accessories

For optimized small parts storage, Kardex offers a variety of purpose-built accessories—including durable, reusable Kardex Boxes. Available in multiple sizes, they support hundreds of location types and can be subdivided for enhanced organization, helping you keep inventory highly visible and easy to access.

Solutions from Kardex

Kardex Shuttle

The Kardex Vertical Lift Module is a dynamic, space-saving storage system designed to enhance small parts picking by bringing goods directly to the operator. By using vertical space efficiently, it eliminates unproductive walking and searching time, reduces picking errors, and increases throughput. Ideal for operations handling a variety of SKUs in different shapes and sizes, the VLM adapts to changing inventory needs while improving organization and visibility. It's the perfect solution for businesses looking to streamline fulfillment and boost accuracy in a compact footprint.

AutoStore Cube Storage

As an official AutoStore partner, Kardex offers a robotic, high-density storage system built for speed, flexibility, and scalability. This cube-based solution is ideal for high-volume small parts picking, allowing you to store significantly more inventory within a limited footprint. Whether you're managing fluctuating demand, expanding your product range, or scaling for growth, AutoStore ensures fast and accurate order fulfillment while maintaining optimal space utilization. It's the go-to system for fast-moving operations that need to keep pace with evolving customer expectations.

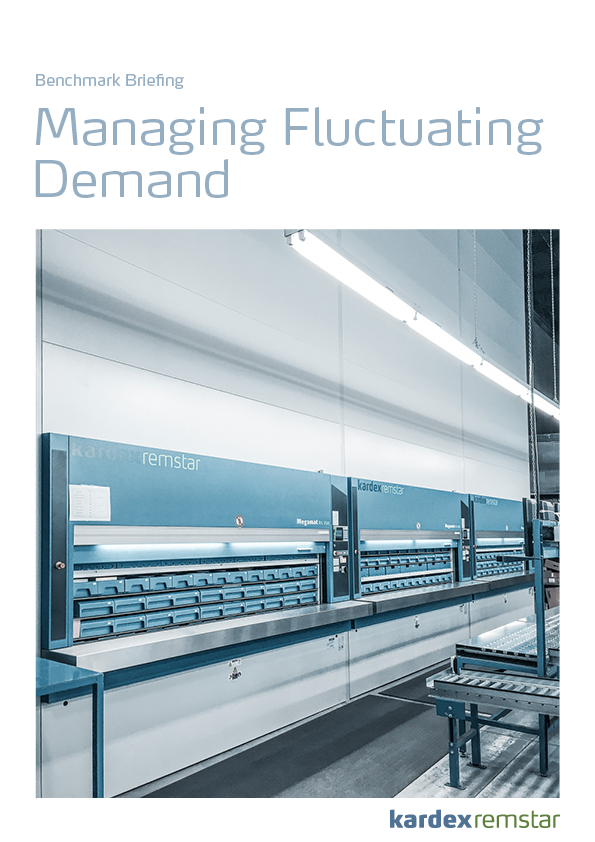

Kardex Megamat

The Kardex Megamat is a vertical carousel engineered for efficient, reliable handling of small parts with consistent dimensions. It uses a rotating shelf system to deliver items directly to the operator, minimizing reach time and improving picking accuracy. With its fast access times, ergonomic design, and compact footprint, the Megamat is especially suited for environments with high picking frequency and uniform product sizes. It simplifies organization, supports batch picking, and ensures your team stays productive while maintaining inventory control.

.jpg)