Production Logistics Solutions

Streamline production logistics with Kardex automated solutions. Maintain seamless inventory flow, ensure just-in-time delivery, and tackle space constraints with customized, scalable systems.

Key challenges in production logistics include managing stock levels, just-in-time delivery, and safely handling sensitive or heavy materials that require special storage conditions. Minimizing manual labor and errors is also crucial for maintaining efficiency. Kardex offers automated solutions that increase inventory accuracy to up to 99.9%, reduce labor costs, and save up to 85% of space. Our flexible, scalable systems ensure seamless production logistics and supply chain efficiency.

Features & Benefits

-

Seamless Inventory Management

Achieve up to 99% inventory accuracy with automated tracking

-

Automated Material Flow

Ensure precise, real-time material handling with automated systems

-

Optimized Space Utilization

Save up to 85% of space with high-density, vertical storage solutions

-

Just-in-Time Delivery

Ensure materials arrive exactly when needed for uninterrupted production

-

Sensitive Material Handling

Safely store and manage fragile or heavy items with customisable conditions

-

Enhanced Worker Ergonomics

Improve safety and reduce strain with ergonomic goods-to-person technology

Seamless Inventory Management

Achieve up to 99% inventory accuracy with automated tracking

Automated Material Flow

Ensure precise, real-time material handling with automated systems

Optimized Space Utilization

Save up to 85% of space with high-density, vertical storage solutions

Just-in-Time Delivery

Ensure materials arrive exactly when needed for uninterrupted production

Sensitive Material Handling

Safely store and manage fragile or heavy items with customisable conditions

Enhanced Worker Ergonomics

Improve safety and reduce strain with ergonomic goods-to-person technology

Customer Success Stories

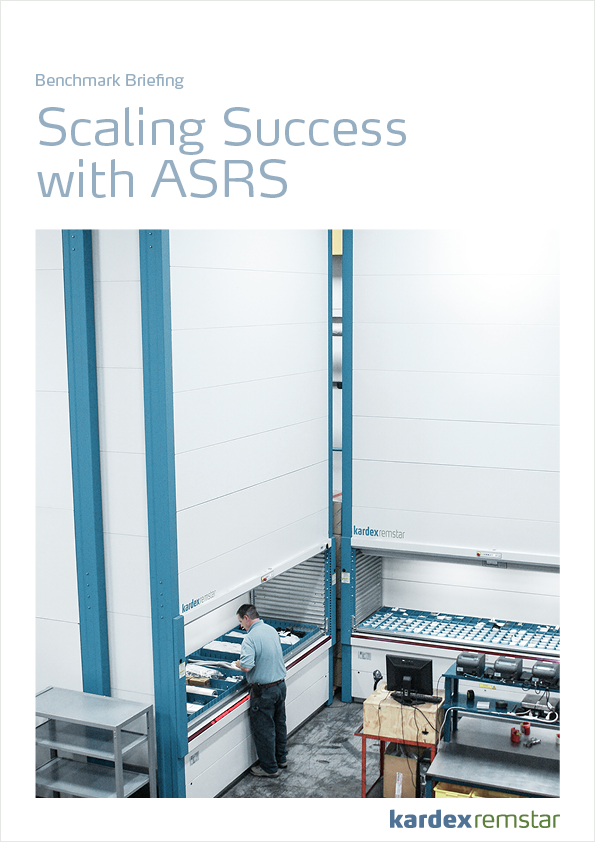

Automating Production For Greater Output

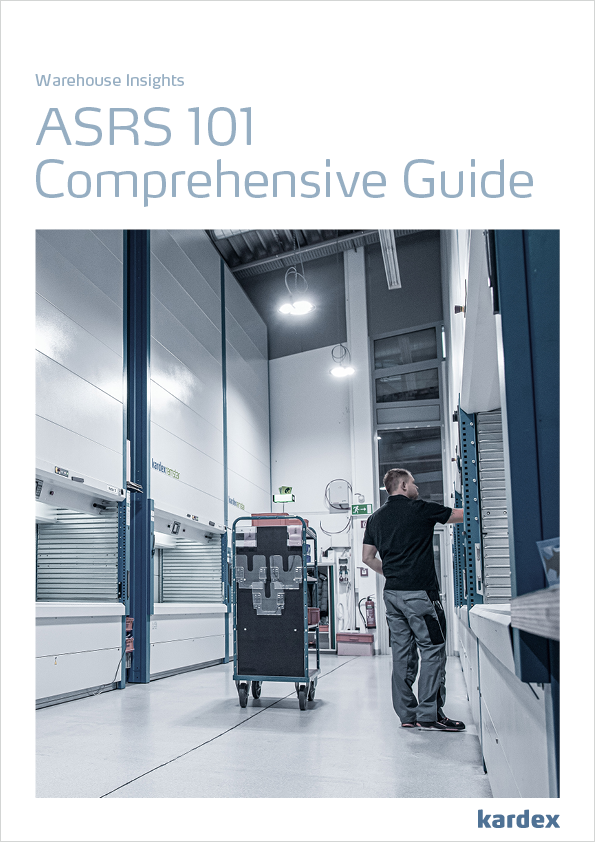

Streamline Production Logistics with Smart Storage Solutions

This guide breaks down key ASRS principles and shows how they enhance buffer storage, accelerate line-side delivery, and support lean manufacturing.

Tailored Production Logistics Solutions

Kardex offers tailored solutions that streamline production logistics, ensuring seamless inventory management, efficient material flow, and just-in-time delivery. Our systems address the key challenges of modern production logistics, helping you optimize operations with ease.

Seamless Inventory Management

Achieve up to 99% inventory accuracy with Kardex automated solutions. Integrated with inventory management software, these solutions provide real-time tracking and full inventory visibility, ensuring smooth production flows and reducing the risk of stockouts or overstocking.

Automated Material Flow

Kardex products minimize manual intervention and errors ensure seamless material movement, optimizing production efficiency.

Just-in-Time Delivery

Ensure materials arrive precisely when needed with Kardex systems. Automated picking and retrieval processes, reduce lead times and keep production lines running smoothly without costly delays. To fully automate processes, Kardex solutions can be connected to conveyors and/or AGVs.

Optimized Space Utilization

By maximize wasted overhead space , Kardex solutions can recover up to 85% of currently occupied floor space, allowing you to store more within the same footprint.

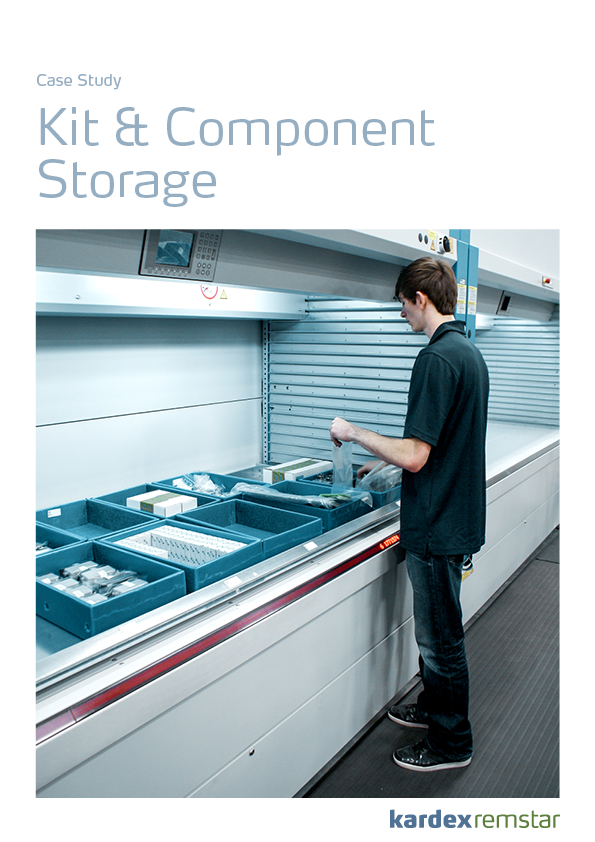

Sensitive Material Handling

Handle fragile, sensitive, or heavy items with ease using Kardex systems. Our systems offer secure, customizable storage environments, ensuring your materials are handled with care while boosting operational efficiency.

Enhanced Worker Ergonomics

Kardex solutions prioritize operator safety. Goods are delivered at ergonomic heights, reducing physical strain and workplace injuries. For heavier loads, units can be equipped with an overhead crane or ergonomic hoist, ensuring safe, efficient operations.

Solutions from Kardex

Kardex Shuttle

The Vertical Lift Module (VLM) is a versatile, space-saving storage solution designed to maximize vertical space and streamline order fulfillment. Ideal for businesses handling a wide range of product sizes, it enhances inventory organization, speeds up picking processes, and supports efficient operations across various channels to meet growing customer demands.

AutoStore Cube Storage

As a global AutoStore partner, Kardex delivers a compact, high-speed solution that allows you to store significantly more inventory without expanding your warehouse footprint. This space-efficient, robotic system offers the speed, flexibility, and scalability needed to fulfill orders faster and adapt to fast-moving, ever-changing inventory demands.

.jpg)