Kardex Miniload-in-a-Box

The Kardex Miniload-in-a-Box is an automated bin storage system built for kitting, sequencing, and buffer inventory—designed to keep materials flowing, even when your process pauses.

The Kardex Vertical Buffer Module (VBM) - or Miniload-in-a-Box - is a compact, automated bin storage system built for high-speed retrieval, intelligent buffering, and streamlined material flow. Whether you’re staging parts between production steps, holding buffer inventory to smooth demand spikes, or organizing kits for assembly, the VBM ensures everything is in the right place at the right time.

Ideal for managing sequencing workflows, kitting stations, or temporary storage between processes, the system uses totes or bins in a high-density layout that maximizes space while minimizing operator movement. With flexible access points, modular design, and seamless integration into existing material handling environments, the Kardex Miniload-in-a-Box is a future-ready solution for dynamic manufacturing and distribution operations.

Vertical Buffer Module Benefits

-

Order Consolidation

Automated order consolidation capabilities

-

Flexible & Scalable

Flexible and scalable design to fit individual needs

-

Modular

Modular up to 65 ft/20 m in length and 39 ft/12 m high

-

Weight Capacity

Capable of handling up to 77 lbs/35 kg per tote

-

Box Handling

Automatic box handling with conveyors

-

Item Picking

Discrete item picking for increased inventory control

Order Consolidation

Automated order consolidation capabilities

Flexible & Scalable

Flexible and scalable design to fit individual needs

Modular

Modular up to 65 ft/20 m in length and 39 ft/12 m high

Weight Capacity

Capable of handling up to 77 lbs/35 kg per tote

Box Handling

Automatic box handling with conveyors

Item Picking

Discrete item picking for increased inventory control

How Does the Kardex Miniload-in-a-Box Work?

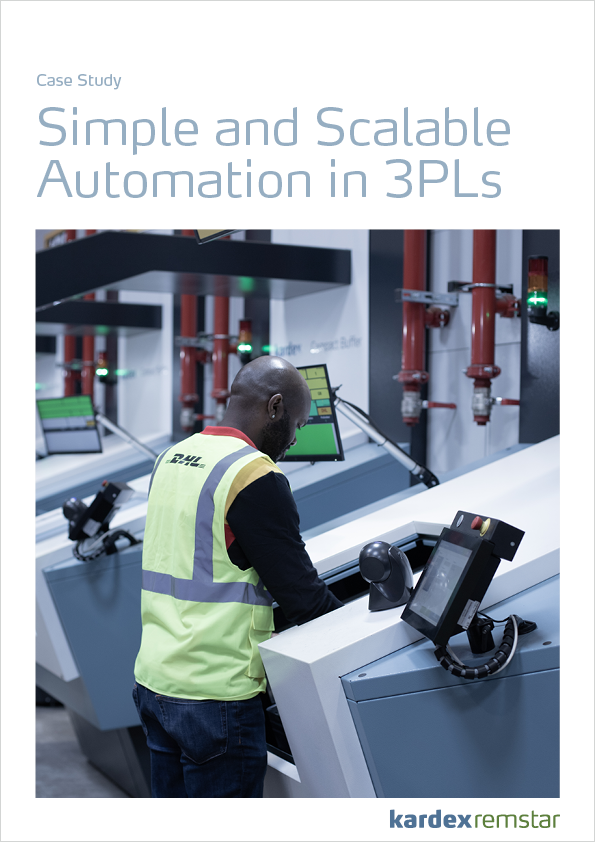

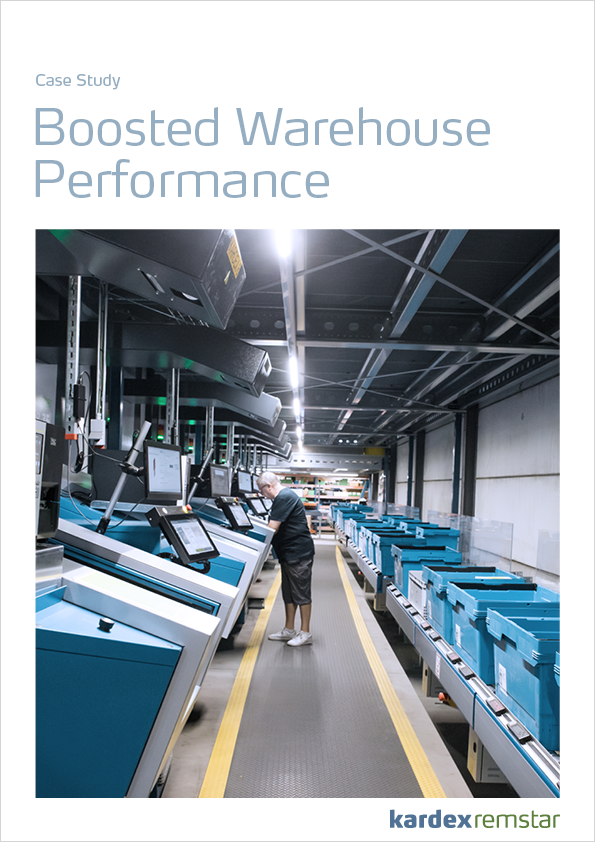

Customer Success Stories

VBM Components, Options, and Features

The VBM’s modular rack system is built on a 25 mm grid, allowing for highly flexible storage of bins and trays. The structure is made up of interconnected vertical support profiles and cross beams, forming stable segments on either side of the center aisle. A precision-mounted base frame with adjustable leveling feet ensures stability even on uneven floors, making the system easy to install and scale over time as your needs grow.

At the core of the VBM is a lightweight, energy-efficient miniload crane with a rotating gripper and telescopic load handling device. This high-speed crane retrieves and stores trays or bins by moving along a horizontal rail and vertically up the mast using a toothed belt drive. For safety during maintenance, a fall arrester is built into the mast—enabling technicians to ascend securely to the necessary height.

The ergonomic picking station features a 20-degree tilted turntable that simplifies access to stored goods. While the operator picks one order, the next bin or tray is staged behind the scenes. Once picking is complete, the turntable rotates 180 degrees, presenting the next bin instantly—reducing idle time and improving throughput without operator strain.

To support advanced workflows, additional access points can be added to the front or rear of the unit. These openings are ideal for manual replenishment or conveyor integration, enabling simultaneous picking, restocking, or buffering. Whether you're streamlining inbound goods or sequencing for outbound orders, these access points make your VBM even more versatile.

The VBM’s integrated, web-based unit control software delivers intuitive operation and advanced functionality—all without the need for a separate PC. Featuring a 10.1-inch capacitive touchscreen (with an optional glove-compatible version), the interface is designed for effortless navigation and operator comfort. From managing bins and stock levels to handling complete storage and retrieval workflows, the software offers full control directly from the unit. Built-in data storage and real-time tracking simplify warehouse tasks and give users the power of classic warehouse management functionality right at their fingertips.

-

Controlled Single Access Opening

Restrict access to specific bins by user role—ideal for safeguarding valuable tools, equipment, or inventory.

-

Height Detection Light Barrier

Automatically detects bin height at each access point, helping ensure accurate storage and preventing misplacement.

-

Safety Limited Speed & Position (SLS/SLP)

Monitors vertical speed and stopping distance in real time to prevent unsafe motion and ensure precise positioning.

-

Clearance Control

Vertical light barriers check for overhanging goods and bin alignment—stopping machine movement if interference is detected.

-

LED Light Pointer

A color-coded light spot highlights the exact pick location, improving speed and accuracy when multiple items share a bin or tray.

-

Confirmation Button

Touch-free confirmation button integrated into the pick station signals successful picks or returns with a visual cue.

-

LED Illumination

Optional overhead LED lighting improves visibility in the access opening and can be toggled directly from the control panel.

-

Optical Status Signal

A color-coded light system guides operators to the correct pick station—ideal for multi-unit or multi-access environments.

Controlled Single Access Opening

Restrict access to specific bins by user role—ideal for safeguarding valuable tools, equipment, or inventory.

Height Detection Light Barrier

Automatically detects bin height at each access point, helping ensure accurate storage and preventing misplacement.

Safety Limited Speed & Position (SLS/SLP)

Monitors vertical speed and stopping distance in real time to prevent unsafe motion and ensure precise positioning.

Clearance Control

Vertical light barriers check for overhanging goods and bin alignment—stopping machine movement if interference is detected.

LED Light Pointer

A color-coded light spot highlights the exact pick location, improving speed and accuracy when multiple items share a bin or tray.

Confirmation Button

Touch-free confirmation button integrated into the pick station signals successful picks or returns with a visual cue.

LED Illumination

Optional overhead LED lighting improves visibility in the access opening and can be toggled directly from the control panel.

Optical Status Signal

A color-coded light system guides operators to the correct pick station—ideal for multi-unit or multi-access environments.

Picking Stations

Tab Navigation

Turntable Pick Station

The turntable is ergonomic and very easy to use due to its 20° tilt.

As soon as the operator has finished picking order line(s) from a bin, the turntable turns through 180° and the next bin is ready for picking. The standard (and minimum) table height is located at 27.16“ (690mm) from the floor but this may be increased in height by increments of 1.97“ (50mm).

This Turntable pick station can be located on the face of the Vertical Buffer Module only.

Single Manual Pick Station

The manual pick station can be located on the front or rear side of the Vertical Buffer Module. The standard (and minimum) table height is located at 28.03“ (712mm) from the floor but this may be increased in height by increments of 1.97“ (50mm).

Conveyor Connection

The Kardex Miniload-in-a-Box easily connects to existing conveyor technology, either for manual storage and retrieval of bins and trays or for automatic operation and transfer to existing material flow.

The connection fits the end face, right, or left side. It is designed to constantly move bins to fill orders automatically and increase order picking performance. Also, replenishment can be done automatically.

Technical Data

| Performance | High order picking performance based on bin cycles and number of order lines. Max. total load 63 metric tons |

|---|---|

| Bins | Standard mini-load system compatible bins 600 x 400 mm (24.6 x 16.3 in) Load 35 kg (77.2 lbs) | bin, Individually designed Kardex VBM Boxes (640 x 440 x 140 mm/25.2 x 17.3 x 5.5 in) are available |

| Width | 1,920 to 19,970 mm (75.6 to 786.22 in) |

| Depth | 2,350 mm & 2450mm (92.5 in & 96.4 in) |

| Height | 3,000 to 12,000 mm (118.11 to 472.44 in) in 100mm steps |

Kardex VBM Box

The Kardex VBM Box is a storage and transport box that includes a flexible divider system. With dimensions 640 x 440 x 140 mm, the box is perfect for the Kardex Miniload-in-a-Box. Storage boxes can be divided or adapted at any time using transverse and longitudinal dividers for increased flexibility. The height extends in a 50 mm grid using push-on frames.

Software Solutions

The Kardex Power Pick System optimizes storage and retrieval in combination with Kardex machines. It covers multiple, smart picking strategies. By streamlining order fulfillment processes, it enhances productivity and ensures greater accuracy in high-demand warehouse environments.

.jpg)