Kardex SnapVac Keep your AutoStore grid clean and operations running smoothly with Kardex SnapVac—our semi-automated robot vacuum for easy and safe system maintenance.

Remove dust and debris from your AutoStore grid to ensure maximum uptime

What is Kardex SnapVac?

Kardex SnapVac is the first semi-automated cleaning robot designed to keep the top of your AutoStore grid free from dust, debris, and operational slowdowns.

Built as an attachment for the AutoStore Red Line series, Kardex SnapVac features a compact vacuum unit mounted on top with a tube running along the robot's body to clean the AutoStore grid surface as it moves.

Key Features

-

Built for Red Line Robots

Integrates with your AutoStore R5, R5+, R5 Pro & R5+ Pro robots for simple deployment—just place it and clean, no reconfiguration required.

-

Monitoring via ServiceConsole

Operators can monitor and track SnapVac activity, runtime, and system status through the ServiceConsole UI.

-

Bagless Debris Collection

The dust and debris collection bin is easy to remove and empty—no disposable vacuum bags, no hassle.

-

Low-Profile Tube Design

A low-profile tube with bristles sweeps and collects dust along the grid as the robot moves—no disruption to robot flow.

-

Up to 80% Debris Removal

Equipped with a bristled head, the SnapVac efficiently captures the majority of dust and debris from the top of the grid.

-

Runs During Normal Operations

Kardex SnapVac cleans without interrupting AutoStore operations, helping you preserve uptime and avoid costly shutdowns.

Built for Red Line Robots

Integrates with your AutoStore R5, R5+, R5 Pro & R5+ Pro robots for simple deployment—just place it and clean, no reconfiguration required.

Monitoring via ServiceConsole

Operators can monitor and track SnapVac activity, runtime, and system status through the ServiceConsole UI.

Bagless Debris Collection

The dust and debris collection bin is easy to remove and empty—no disposable vacuum bags, no hassle.

Low-Profile Tube Design

A low-profile tube with bristles sweeps and collects dust along the grid as the robot moves—no disruption to robot flow.

Up to 80% Debris Removal

Equipped with a bristled head, the SnapVac efficiently captures the majority of dust and debris from the top of the grid.

Runs During Normal Operations

Kardex SnapVac cleans without interrupting AutoStore operations, helping you preserve uptime and avoid costly shutdowns.

Cleaning Your AutoStore Grid

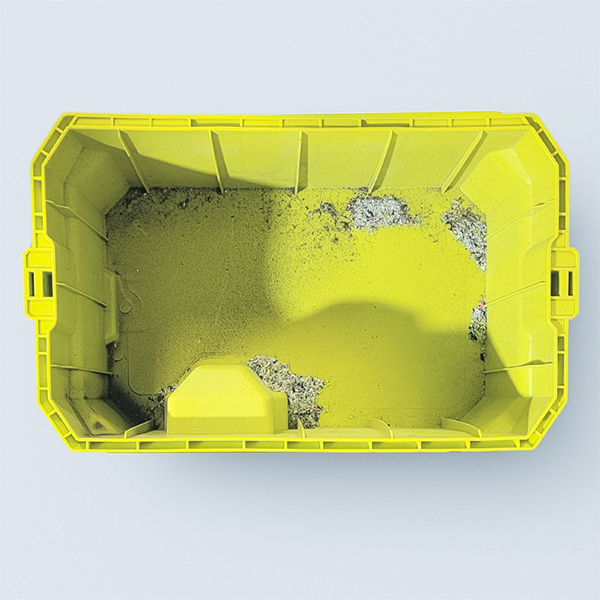

Debris & Dust Collected

Even in the cleanest, best-maintained warehouse environments, dust and debris are inevitable. The image shows the interior of the Kardex SnapVac collection bin that was used during a grid cleaning. With no special preparation, the vacuum collected visible debris from the AutoStore grid—proof that particles accumulate quickly and silently, even with routine care. Over time, this buildup can impact robot performance and contaminate bins. That’s why regular, intentional cleaning is essential—and our solution makes it simple to stay ahead of the mess.

Justify Your AutoStore Investment

Calculate your ROI, uncover annual labor savings, and see how AutoStore can reduce your storage footprint by up to 4X — all without expanding your facility.

Benefits

-

Extends Robots' Lifespan

by reducing exposure to dust, dirt, and particles

-

Reduces Operational Disruption

due to errors caused by debris buildup

-

Promotes Workplace Safety

by removing the need for human intervention on top of the grid

-

Reduces Cleaning Downtime

with no need to pause or shut down the system for manual cleaning

-

Prevents Inventory Contamination

and ensures clean storage bins

-

Reduces Maintenance Efforts

required to manually clean the grid

Extends Robots' Lifespan

by reducing exposure to dust, dirt, and particles

Reduces Operational Disruption

due to errors caused by debris buildup

Promotes Workplace Safety

by removing the need for human intervention on top of the grid

Reduces Cleaning Downtime

with no need to pause or shut down the system for manual cleaning

Prevents Inventory Contamination

and ensures clean storage bins

Reduces Maintenance Efforts

required to manually clean the grid

Track Cleaning Progress

Gain real-time visibility into your grid cleaning progress with AutoStore’s ServiceConsole interface.

The Clean Grid view—shown below—lets operators easily track where and how thoroughly the vacuum has cleaned:

- Light green cells indicate areas cleaned in one direction

- Dark green cells show full two-way coverage

* Illustrative purposes only. Grid layout and routing patterns shown may differ from actual system behavior and scale.

Ensure Full Coverage: Instantly verify which sections of the grid have been cleaned and which still need attention

Optimize Cleaning Time: Know exactly when to stop or restart the robot for maximum efficiency

Plan Smarter Maintenance: Use visual logs to support proactive upkeep and reduce reactive grid issues

Increase Operator Confidence: Operators can monitor progress and performance without needing to physically inspect the grid

Insights

More Solutions by Kardex

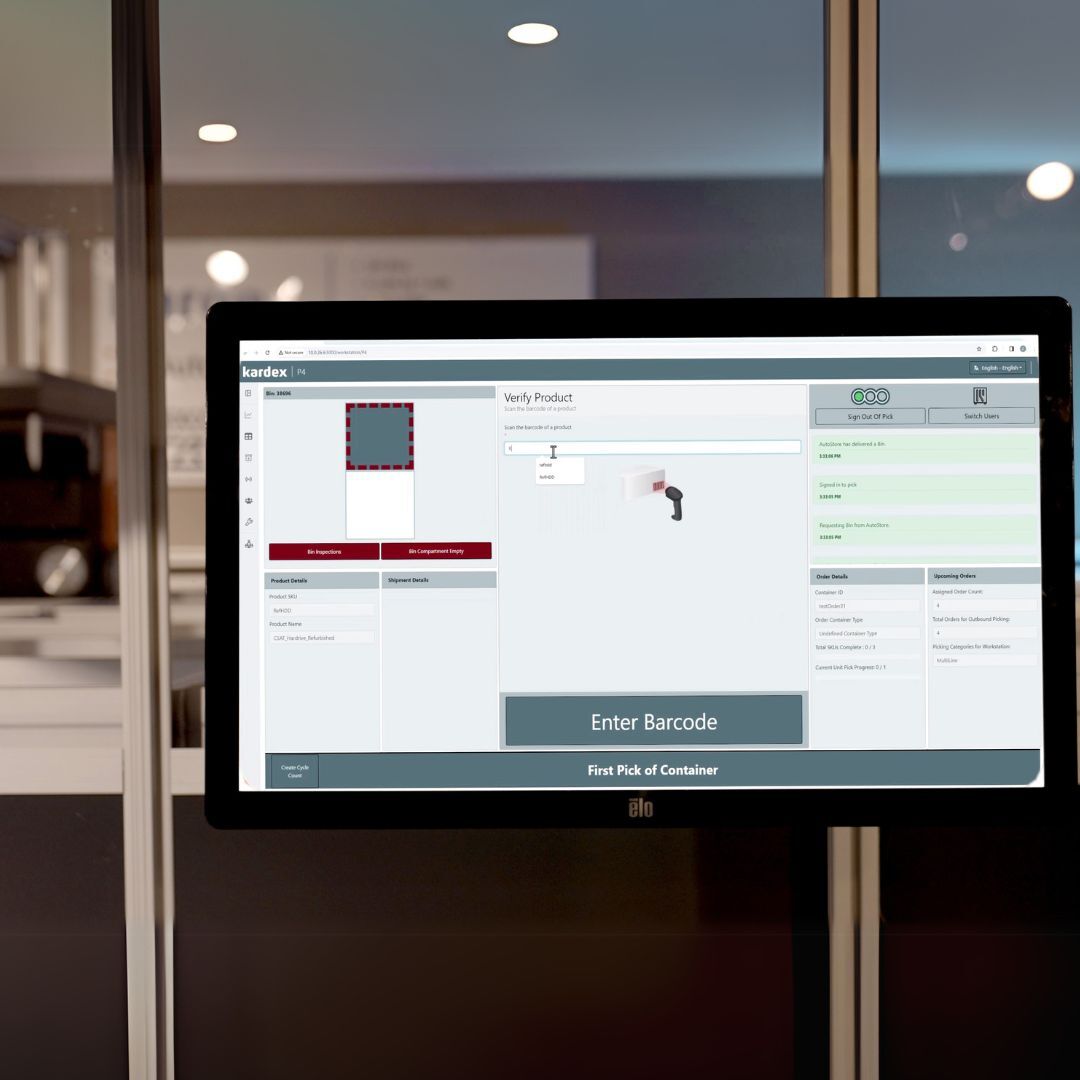

Kardex FulfillX Software

Kardex FulfillX is a warehouse execution system (WES) specifically designed to streamline operations and enhance performance for AutoStore. It is a purpose-built software solution offered by Kardex to optimize the utilization of AutoStore robots, operators, inventory accuracy, and flexibility in the warehouse environment.

Intuitive Picking Assistant

The Intuitive Picking Assistant elevates picking processes of AutoStore™ solutions to the next level. By projecting all relevant picking information, it guides the operator through the picking process.

.jpg)