%20(1).png)

%20(1).png)

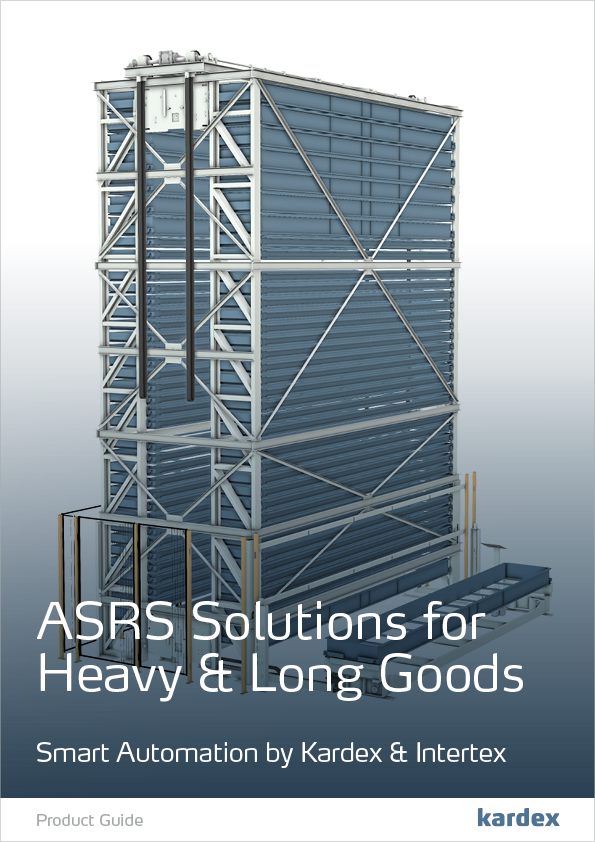

Kardex TowerMat Vertical Lift Module

Vertical lift storage for heavy, long, and oversized goods

Kardex TowerMat is a vertical lift system engineered specifically for stock with extreme dimensions and heavy loads. Long goods, sheet metal, tools, pallets, and mesh cages that overwhelm conventional racking can all be consolidated into a single, high-density vertical footprint. Each carrier is built for very high load capacities and can be configured around your exact item dimensions and handling methods, so you gain storage capacity without giving up control or safety.

Efficient, Space-Saving Warehouse Storage

Stock that is long, flat, or extremely heavy tends to sprawl. Storing metal sheets, bar stock, pallets, or cages on the floor or in deep rack bays eats up valuable space and often requires forklifts and multiple touches to access a single item. TowerMat addresses this by lifting that inventory into a tall steel structure and delivering each carrier to an access opening at ground level. You trade low, sprawling storage for a compact vertical system that is easy to access and simple to manage.

You can configure TowerMat as a single-tower unit for lower buildings or a double-tower system that reaches heights of roughly 100 feet, with carrier widths of up to about 40 feet and depths of up to about 7 feet, depending on the model and application.

How the Kardex TowerMat Vertical Lift Module Works

TowerMat uses the same core principle as a Vertical Lift Module, scaled for heavy and long goods. Carriers are arranged in a vertical framework and moved by an elevator mechanism. When a carrier is requested, the lift travels to the correct position, picks up the carrier, and brings it to the access opening at floor level.

Operators and material handling equipment work at a fixed, controlled interface instead of reaching into deep rack positions or elevated beams. Heavy loads stay on the carrier, which reduces the risk of damage to both product and people and keeps handling repeatable from one shift to the next.

Automated Storage and Retrieval for Heavy Duty Parts and Goods

Tools, Dies, And Molds Storage

Storing heavy tools and molds is especially challenging. Loads are often irregular and extremely dense, and they need to be accessed frequently for production. Towermat carriers can be outfitted with custom supports, cradles, and fixture frames so tools and molds are stored securely and presented at the access opening where an overhead crane can take over the lift. This combination of tailored carrier design and crane handling gives you both high storage density and safe retrieval.

Pallets And Mesh Cages Storage

For palletized materials and mesh cages, TowerMat acts as a vertical pallet buffer. Each tray can store a mix of heavy load carriers, with options such as integrated lift and sink stations and double-bottom carrier designs that support different pallet sizes side by side. Multiple Euro-style pallets can be stored across a single tray width, which lets you pack more material into the same footprint while still presenting everything at a standard loading height.

Long Goods Storage

Pipes, steel bars, and similar long items can be difficult to store safely and efficiently. TowerMat is designed so long goods up to roughly 39 feet in length can be stored on carriers and transported automatically to the access opening. High load capacities, compact footprint, and very high storage density make it well suited for bar stock, structural profiles, and other long products. Carriers can also be positioned to feed saws or cutting equipment directly.

.png)

Sheet Metal and Large Flat Goods Storage

For large flat products, such as sheet metal panels, the TowerMat VLM provides carriers sized for materials up to about 6.5 by 19.5 feet. These sheets are stored vertically and delivered automatically to the operator, with each tray designed to handle several tons of material. Single-tower and double-tower variants are available so you can match storage volume and building layout without giving up access speed.

Technical Specifications

| TowerMat FE (Double-Tower) | TowerMat EE (Single-Tower) | |

|---|---|---|

| System Height System Height | Up to 95 ft 5 in Up to 95 ft 5 in | Up to 26 ft 3 in Up to 26 ft 3 in |

| Carrier Unit Width Carrier Unit Width | up to 40 ft up to 40 ft | Up to 26 ft 11 in Up to 26 ft 11 in |

| Carrier Unit Depth Carrier Unit Depth | Up to 6ft 11in Up to 6ft 11in | Up to 4 ft 11 in Up to 4 ft 11 in |

| Max Load per Carrier Max Load per Carrier | Up to 11,023 lb Up to 11,023 lb | Up to 6,614 lb Up to 6,614 lb |

Is Kardex TowerMat Right for Your Operation?

Download our buyer's guide to learn more about how we can help you store long, heavy parts while making the most use of your vertical space.

Heavy-Duty Vertical Lift Module Benefits

-

Space Utilization

Floor stacks and deep rack bays are replaced by a tall, compact footprint that uses your full building height. This opens up room for additional production, staging, or new equipment.

-

Safer Handling

Heavy loads stay on engineered carriers and are moved with lift systems, forklifts, or cranes at a defined interface. That reduces awkward manual lifting and lowers the risk of injury when handling large or irregular items.

-

Faster, Trackable Access

Instead of hunting for the right pallet, bundle, or sheet, operators request a carrier and receive it at the same access opening every time. Travel and search time go down, and material flow becomes easier to plan and schedule.

Space Utilization

Floor stacks and deep rack bays are replaced by a tall, compact footprint that uses your full building height. This opens up room for additional production, staging, or new equipment.

Safer Handling

Heavy loads stay on engineered carriers and are moved with lift systems, forklifts, or cranes at a defined interface. That reduces awkward manual lifting and lowers the risk of injury when handling large or irregular items.

Faster, Trackable Access

Instead of hunting for the right pallet, bundle, or sheet, operators request a carrier and receive it at the same access opening every time. Travel and search time go down, and material flow becomes easier to plan and schedule.

Integrated With Your Material Flow

TowerMat installations are customized to both your building and your workflows. Units can be:

-

Installed as single or double towers

-

Integrated with pits or mezzanines

-

Positioned along production lines, cutting stations, or shipping docks

Carriers can interface with saws, overhead cranes, pallet jacks, or conveyors, so heavy goods move directly from storage to the next step in your process. When connected to Kardex Power Pick System and your existing ERP or WMS, every carrier and position can be tracked in real time for better inventory visibility.

Explore More Solutions from Kardex

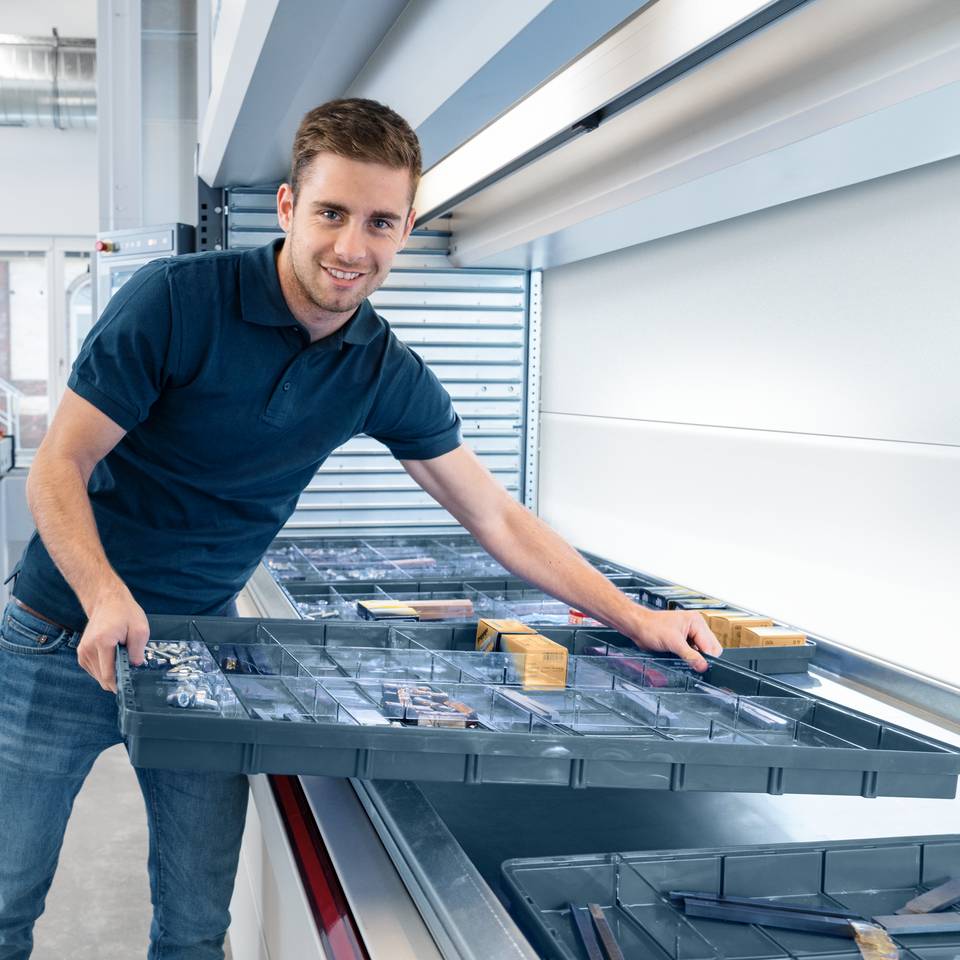

Kardex Shuttle Vertical Lift Module (VLM)

For small and medium-sized parts, mixed SKUs, and many heavy components that do not require long-goods carriers, the Kardex Shuttle Vertical Lift Module (VLM) provides compact, tray-based storage with strong load capacities and fast, goods-to-person access. Shuttle VLMs are a great fit for dense parts storage, kitting, and order picking, and they integrate easily with inventory management software and existing WMS or ERP systems. Together with Towermat, they give you a flexible way to handle everything from bulky stock to high-SKU small parts in a single, unified automation strategy.

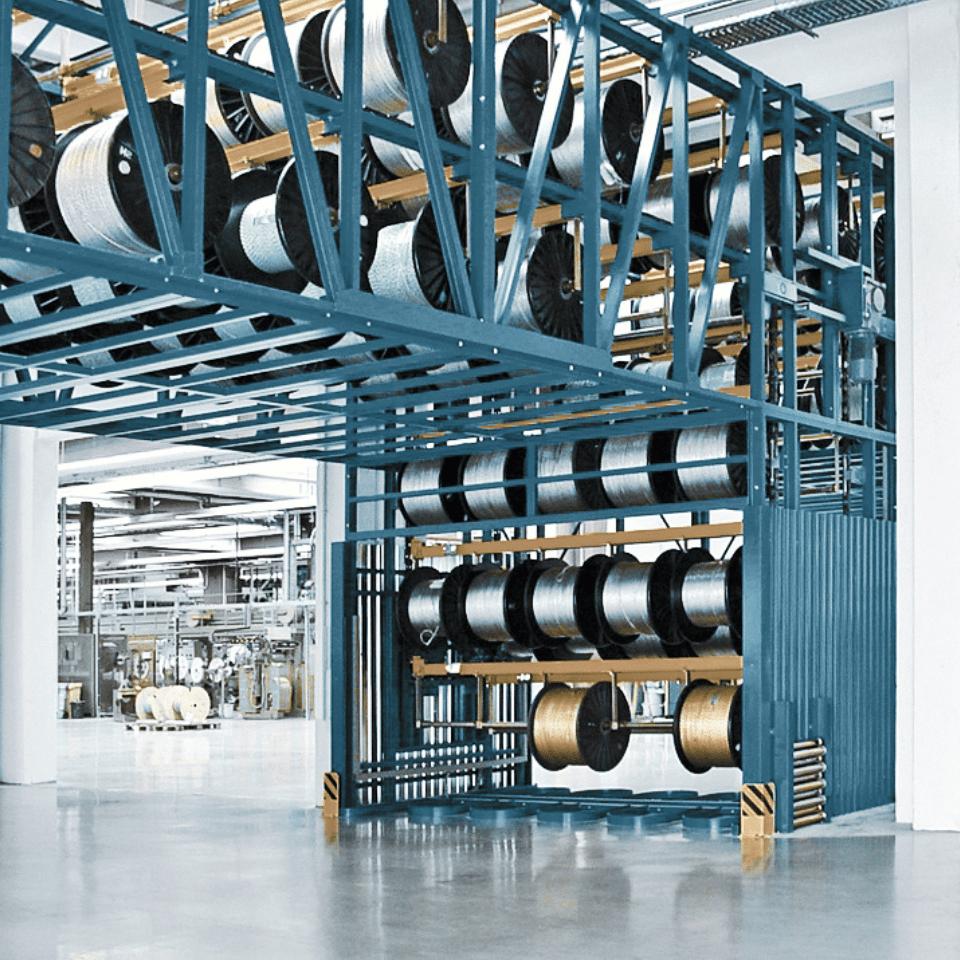

Kardex Intermat Vertical Carousel Module (VCM)

If you also store heavy round loads like cable reels, drums, or tires, Kardex Intermat is the natural companion to Towermat. Intermat is a vertical carousel designed specifically for rolled and round goods, using overhead space and challenging room layouts to create high-density storage while keeping every reel or tire easily accessible at an ergonomic height. It is ideal for operations that want safer, more organized reel and tire handling without giving up valuable floor space.

.jpg)