Warehouse Packing & Shipping Solutions

Kardex offers intuitive automated solutions to help increase productivity in packing and shipping. Reduce search times and optimize packaging and shipping with just-in-time and just-in-sequence item delivery, all while maintaining real-time inventory visibility.

Through integrated sequencing and automated buffering, Kardex solutions help alleviate packing bottlenecks, streamline consolidation, and support semi- or fully-automated workflows that reduce labor and optimize space.

Features & Benefits

-

Order Readiness Notification

Packers are alerted when all items for an order are ready for packing

-

Sequenced Delivery of Goods & Items

Packers receive items in the optimal order for efficient packing

-

Just-in-Time Order Processing

Orders are picked, packed and shipped exactly when needed

-

Accurate Inventory Tracking

Every item is scanned to ensure up-to-date and accurate inventory management

-

Reduce Shipping Bottlenecks

Items are packed in the optimal order, ensuring smooth and efficient loading

-

Optimize Space Utilization

Minimize floor space requirements while supporting fast, accurate order fulfilment

Order Readiness Notification

Packers are alerted when all items for an order are ready for packing

Sequenced Delivery of Goods & Items

Packers receive items in the optimal order for efficient packing

Just-in-Time Order Processing

Orders are picked, packed and shipped exactly when needed

Accurate Inventory Tracking

Every item is scanned to ensure up-to-date and accurate inventory management

Reduce Shipping Bottlenecks

Items are packed in the optimal order, ensuring smooth and efficient loading

Optimize Space Utilization

Minimize floor space requirements while supporting fast, accurate order fulfilment

Automated Packing & Shipping Solutions

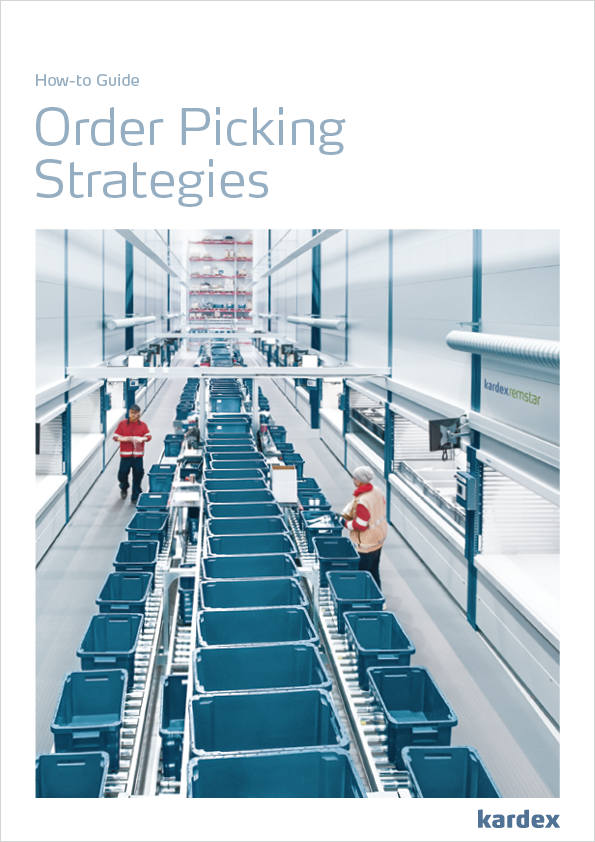

Packing and Shipping Efficiency Starts with the Right Picking Strategy

Whether you are scaling operations or aiming to streamline your process, this how-to guide explains key picking strategies such as zone, batch, and wave picking.

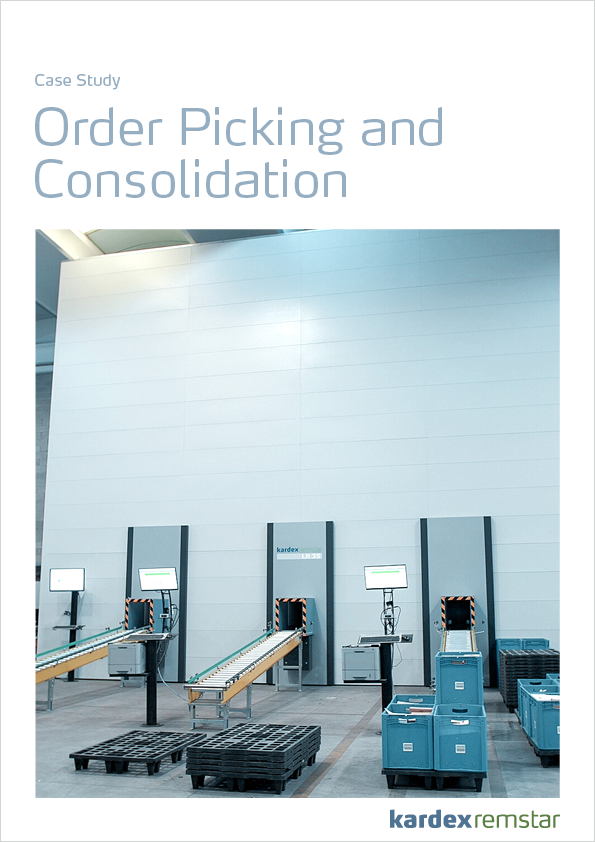

Automated Packing & Shipping Case Study

Warehouse Solutions for Packing & Shipping

Whether you’re looking to streamline order readiness, ensure accurate packaging, or eliminate shipping bottlenecks, Kardex provides scalable solutions that fit your specific needs.

Order Readiness Notification

Kardex software solutions can notify packers the moment that all items for an order or kit are ready. This eliminates delays and increases packing efficiency. Real-time communication between systems ensures complete orders are released to operators as soon as they're ready with no manual checks or validations required.

Sequenced Item Delivery

Having trouble with packing errors and workflow during high-demand times? With Kardex solutions, your items are delivered in the exact sequence required, whether for individual orders or production kits. Heavy items arrive first to reduce damage and improve safety, while pre-sorted order logic ensures minimal dock dwell time and faster outbound flow. Easily integrate automated storage technology with your inventory management software to ensure timely and accurate order fulfillment.

Real-Time Inventory Tracking

Our automated solutions ensure every item is tracked and scanned, providing up-to-date inventory visibility. Integrated software ensures transparent inventory management and reduces the risk of packing or shipping errors. This provides real-time control over inventory levels.

Consolidated Order Shipping

Our solutions can act as an automated consolidation buffer to ensure that all components of a shipment are packed and shipped together. This optimization reduces shipping errors and ensures that products arrive in great condition. Your team can manage both partial and completed orders; so it’s never been easier to save space, improve delivery times, and complete orders – fast.

Smart Cartonization

Packing is optimized through intelligent cartonization, powered by Paccurate, seamlessly integrated with AutoStore and FulfillX. The system selects the ideal outbound carton based on item dimensions, crushability, and carrier rate cards, then determines the most efficient way to pack each order. This reduces freight costs by 6–8% and cuts corrugated and void fill usage by up to 30%, enabling smarter, more sustainable shipping at scale.

Customer Success Stories

Solutions from Kardex

CarouselAI

CarouselAI™ is a smart automation solution that streamlines picking and packing. It combines AutoStore's high-density storage, advanced robotic arm technology, and Kardex's intelligent FulfillX software to reduce handling time, speed up order fulfillment, and improve accuracy.

Kardex Miniload-in-a-Box

The Kardex Miniload-in-a-Box streamlines packing and shipping by enabling high-speed handling, order consolidation, and smart buffer storage. This compact, scalable system integrates easily into existing workflows, helping distribution and warehouse operations boost throughput, reduce packing time, and adapt quickly without complex customization.

Intelligent Cartonization

For high-efficiency packing and shipping, we integrate AutoStore with Paccurate’s smart cartonization engine via Kardex FulfillX execution software. Orders are picked, sequenced, and automatically matched with the optimal carton, then cubed for ideal item placement—reducing freight costs, packaging waste, and manual effort in fast-paced fulfillment environments.

.jpg)