CarouselAI™ Fully automate your order fulfillment with CarouselAI™ —a purpose-built robotic arm, fully integrated with Kardex FulfillX for high-throughput, 24/7 order fulfillment with no added complexity or third-party software.

Enabling around-the-clock fulfillment and order buffering with a fully-automated order picking solution.

CarouselAI™ is a robotic picking solution designed to streamline fulfillment by combining AutoStore’s high-density storage with intelligent, high-speed robotic arms. Integrated through Kardex FulfillX, it eliminates manual picking bottlenecks, enhances throughput, and enables 24/7 operations. CarouselAI™ helps you scale faster, ship sooner, and optimize labor resources—all within your existing facility.

What Is CarouselAI?

Features & Benefits

-

Enables Same-Day Fulfillment

With around-the-clock picking at rates up to 650 picks per hour.

-

Reduces Labor Dependency

Labor can be hard to find — robots work 24/7.

-

Extends Current Operations

Maximize the throughput & efficiency of your existing facility before considering relocation.

-

Enables Off-Hour Order Readiness

CarouselAI can pick items into a single order bin which can be re-inducted into the AutoStore for overnight buffering.

-

Wide Range of SKUs

Adapts to new SKUs without human intervention or training via advanced self-learning technology.

-

Compatible With CarouselPorts

Deploy CarouselAI on new or existing AutoStore systems that utilize the popular CarouselPort™.

Enables Same-Day Fulfillment

With around-the-clock picking at rates up to 650 picks per hour.

Reduces Labor Dependency

Labor can be hard to find — robots work 24/7.

Extends Current Operations

Maximize the throughput & efficiency of your existing facility before considering relocation.

Enables Off-Hour Order Readiness

CarouselAI can pick items into a single order bin which can be re-inducted into the AutoStore for overnight buffering.

Wide Range of SKUs

Adapts to new SKUs without human intervention or training via advanced self-learning technology.

Compatible With CarouselPorts

Deploy CarouselAI on new or existing AutoStore systems that utilize the popular CarouselPort™.

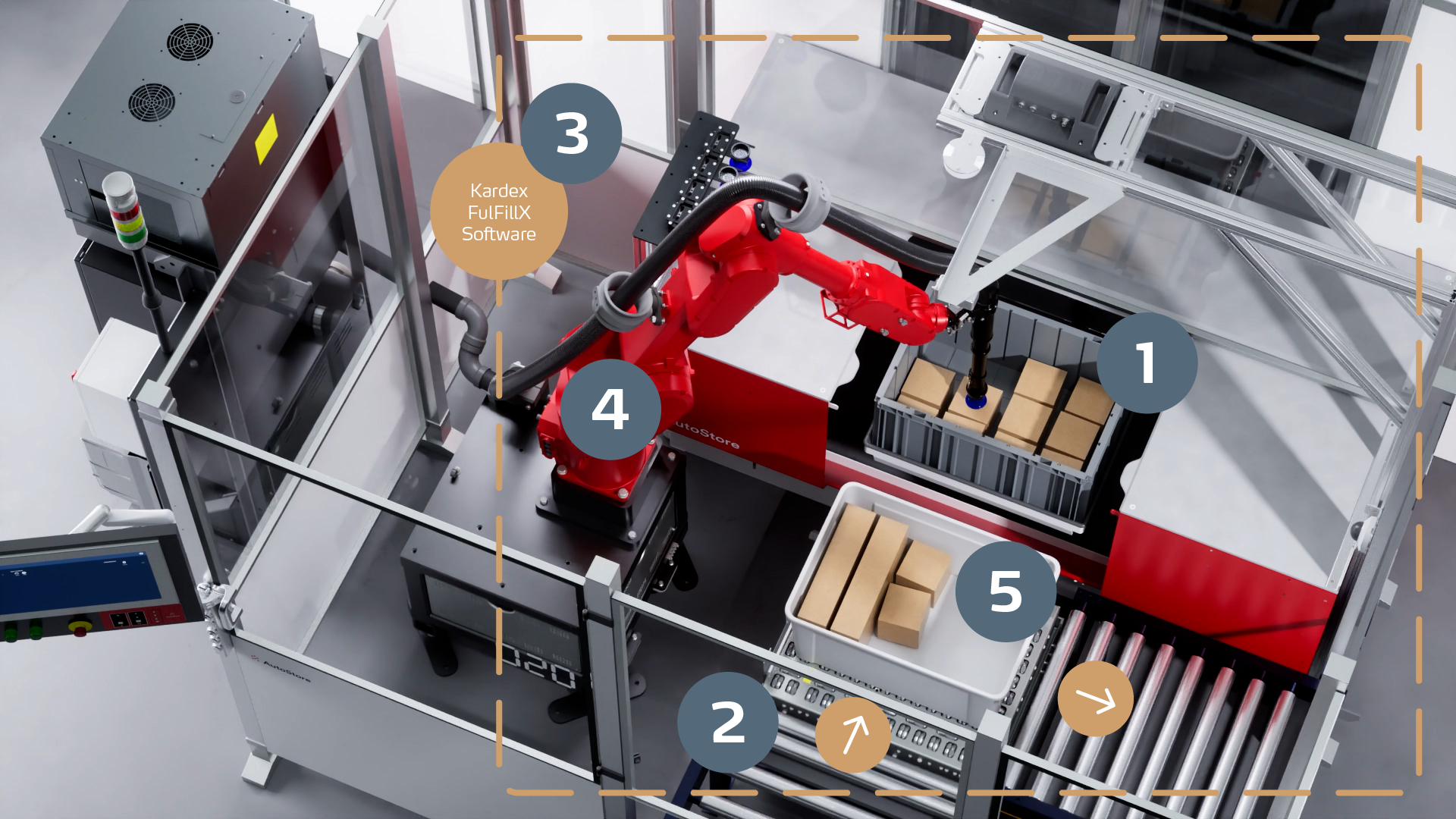

How CarouselAI Works

- Inventory Bins Delivered to AutoStore Port

The AutoStore robots retrieve inventory bins out of the storage grid and deliver them to the CarouselPort. - Outbound Containers Arrive to Pick Cell

An in-feed conveyor transports totes or cartons directly to the picking cell to receive items for outbound shipment. - Kardex FulfillX Dictates The Location, Order, and Quantity

FuflillX acts as the integration hub between AutoStore and CarouselAI, controlling the bin compartment and quantity for each pick. It dictates the location, order, and quantity for the robot to pick, ensuring seamless coordination between AutoStore and the robotic system. - Optimal Grasp & Placement Location Identified

Perception module identifies optimal grasp point of the item in the inventory bin and the optimal placement position in the outbound tote or container. - Item Is Picked and Placed

The robotic arm picks the item from the inventory bin and places it in an outbound container.

Is AutoStore worth the investment?

Calculate your ROI, uncover annual labor savings, and see how AutoStore can reduce your storage footprint by up to 4X — all without expanding your facility.

Proven Integration with Kardex FulfillX

Do I need a 3rd-party software to integrate CarouselAI with AutoStore?

Not with Kardex. Our in-house software, FulfillX, seamlessly integrates AutoStore with robotic picking—eliminating the need for additional third-party software. Purpose-built for AutoStore, Kardex FulfillX is a proven solution that ensures smooth, efficient, and intelligent automation.

How FulfillX powers CarouselAI:

- Location – It determines exactly which bin compartment contains the required item, ensuring the robotic arm picks from the correct position.

- Order – It sequences the picks efficiently, minimizing movement and maximizing throughput.

- Quantity – It dictates the precise number of units to be picked from each bin, ensuring order accuracy and reducing errors.

- Flexibility - adds flexibility to the WMS to drive product sequencing within a container. For example, it ensures heavier products are placed at the bottom to prevent damage to lighter items on top, enhancing both order integrity and packing efficiency.

Your AutoStore Partner — Kardex

-

Fastest growing AutoStore partner

In just a few years, our dedicated AutoStore team has 100+ projects across 19 countries.

-

Lowest total cost of ownership

We are continuously innovating solutions to empower system efficiency and reduce operational costs.

-

AutoStore performance powerhouse

With 99.96% system uptime and 97.95% global availability, Kardex is a reliable partner to ensure that your AutoStore can meet your fulfillment needs.

-

1,300+ AutoStore projects completed

Our team brings extensive hands-on experience to AutoStore solutions, having completed over 1,300 projects throughout their careers.

-

200+ AutoStore-dedicated professionals

Our team of 200+ in-house experts solely focuses on AutoStore projects, ensuring professional execution from design to deployment.

-

350+ years of AutoStore experience

With over 350 years of collective experience, our team has planned, designed, and implemented AutoStore solutions worldwide.

Fastest growing AutoStore partner

In just a few years, our dedicated AutoStore team has 100+ projects across 19 countries.

Lowest total cost of ownership

We are continuously innovating solutions to empower system efficiency and reduce operational costs.

AutoStore performance powerhouse

With 99.96% system uptime and 97.95% global availability, Kardex is a reliable partner to ensure that your AutoStore can meet your fulfillment needs.

1,300+ AutoStore projects completed

Our team brings extensive hands-on experience to AutoStore solutions, having completed over 1,300 projects throughout their careers.

200+ AutoStore-dedicated professionals

Our team of 200+ in-house experts solely focuses on AutoStore projects, ensuring professional execution from design to deployment.

350+ years of AutoStore experience

With over 350 years of collective experience, our team has planned, designed, and implemented AutoStore solutions worldwide.

Helpful Resources

Intuitive Picking Assistant

The Intuitive Picking Assistant elevates picking processes of AutoStore™ solutions to the next level. By projecting all relevant picking information it guides the operator through the picking process.

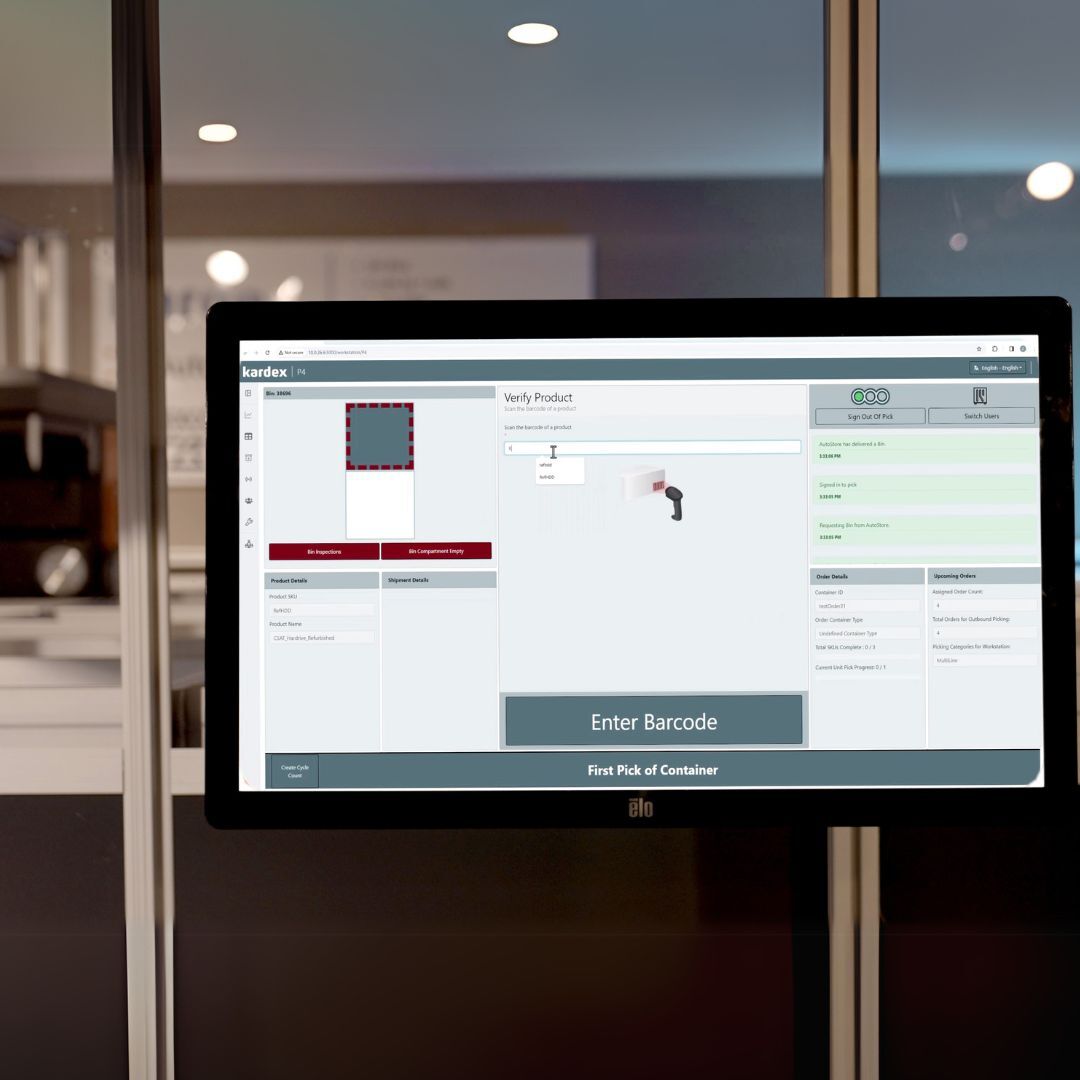

Kardex FulfillX Software

Kardex FulfillX is a warehouse execution system (WES) specifically designed to streamline operations and enhance performance for AutoStore. It is a purpose-built software solution offered by Kardex to optimize the utilization of AutoStore robots, operators, inventory accuracy, and flexibility in the warehouse environment.

Kardex SnapVac

Kardex SnapVac is the first cleaning robot designed to keep the top of your AutoStore grid free from dust, debris, and operational slowdowns.

.jpg)