Kardex Horizontal Carousel

Maximise efficiency with the Kardex Horizontal Carousel, designed for fast, reliable, and cost-effective storage and retrieval of goods.

The Horizontal Carousel Module (HCM) works particularly well in facilities with low ceilings or double stacked to maximise capacity in facilities with taller ceilings. HCMs are ideal for managing medium and slow-moving SKUs requiring high throughput rates.

Features & Benefits

-

High Throughput

Items are delivered to the operator quickly via the shortest path.

-

Flexible Design

Flexible design and layout of workstations and carriers.

-

High Payloads

Storing items with a maximum payload of 54 tons.

-

High Picking Accuracy

Pick-to-light and put-to-light displays enable accuracy rates of over 99%.

-

Optimal Space Utilisation

Items are stored compactly and the actual picking zone can be as small as 5 to 10 sqm.

-

Variability and Flexibility

To achieve high throughput the system can divide into different work zones at the push of a button.

High Throughput

Items are delivered to the operator quickly via the shortest path.

Flexible Design

Flexible design and layout of workstations and carriers.

High Payloads

Storing items with a maximum payload of 54 tons.

High Picking Accuracy

Pick-to-light and put-to-light displays enable accuracy rates of over 99%.

Optimal Space Utilisation

Items are stored compactly and the actual picking zone can be as small as 5 to 10 sqm.

Variability and Flexibility

To achieve high throughput the system can divide into different work zones at the push of a button.

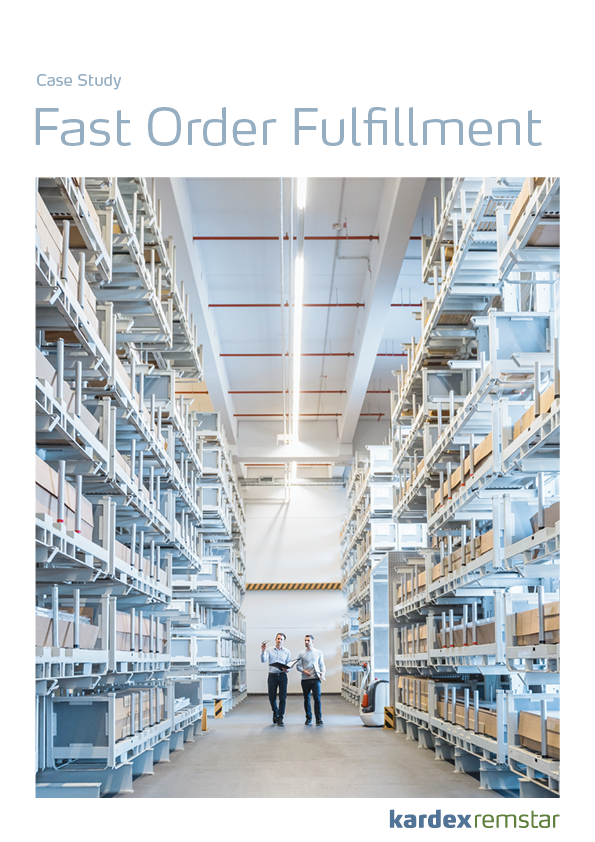

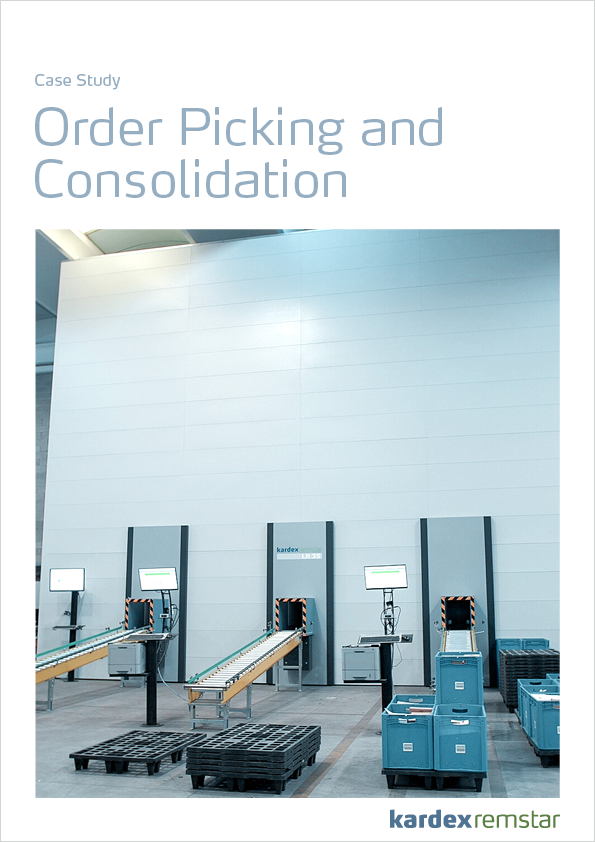

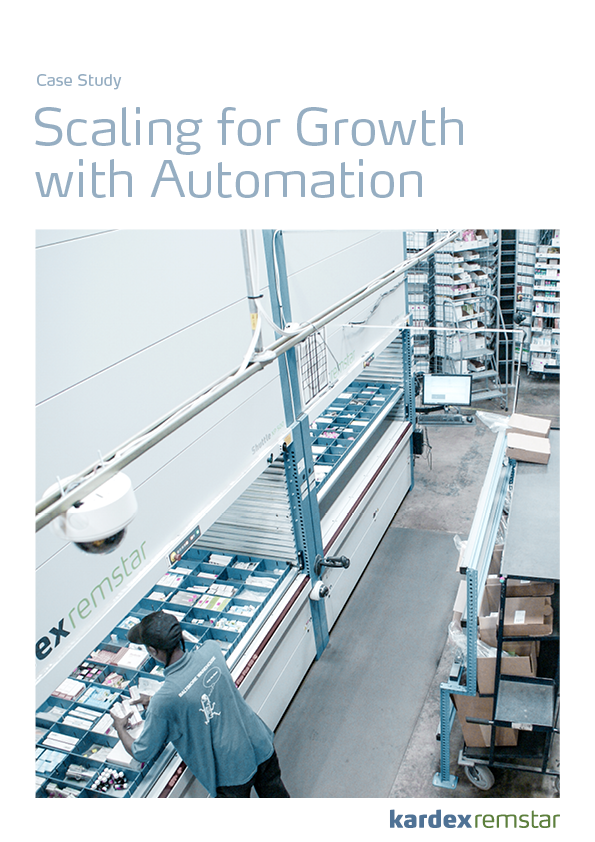

Customer Success Stories

How does the Kardex Horizontal Carousel work?

Optimise Your Warehouse with the Kardex Horizontal Carousel

The Kardex Horizontal Carousel delivers goods quickly and accurately, ensuring minimal handling and retrieval time. Each unit within a station operates simultaneously to provide continuous access and reduce waiting time.

Increase productivity with the simple push of a button. Split a pod of six units, operated by one worker, into three zones operated by three workers. During peak times, multiple workstations allow several workers to pick simultaneously, optimising workflow efficiency.

The Kardex Horizontal Carousel is perfect for smaller buildings with low ceilings, as it optimises the entire horizontal space of the warehouse. Storing items in a compact area (5 to 10 square metres) significantly reduces travel and picking times, enhancing overall efficiency.

Kardex offers tailored solutions to meet diverse industry requirements with a variety of layouts and workstations. Choose between dual, triple, quadruple, and multilevel workstations to fit your specific needs.

Technical Data

| Carousel length | Spalte 1 5,900 mm to 46,700 mm |

|---|---|

| Spalte 1 Number of carriers | Spalte 1 Dependent on the carrier width (CW): CW 622 mm: 16 to 120 carriers | CW 825 mm: 14 to 100 carriers | CW 960 mm: 12 to 90 carriers |

| Spalte 1 Carrier width | Spalte 1 622 mm, 825 mm, 960 mm |

| Spalte 1 Carrier depth | Spalte 1 460 mm, 560 mm, 610 mm |

| Spalte 1 Carrier height | Spalte 1 1,854 mm to 3,658 mm |

| Spalte 1 Carrier payload | Spalte 1 450 kg, 680 kg and 900 kg |

More Solutions from Kardex

Kardex Shuttle

A high-density automated storage and retrieval system that maximises storage capacity while optimising picking and retrieval processes. It is suitable for a wide range of industries and products of various dimensions. The Kardex Shuttle can be integrated with other Kardex solutions.

Controlled Environment

Parts, raw materials, and products often require special storage conditions. Depending on your needs, choose from four controlled environment solutions, which can be integrated into your storage and retrieval system. This results in optimal protection for sensitive goods at all times!