EagleBurgmann modernizes its logistics at the Eurasburg site with the AutoStore solution from Kardex

16 January 2024, Company News

The EagleBurgmann Group, a leading international manufacturer of industrial sealing technology, is preparing for the future. With the implementation of Kardex AutoStore, the production site in Eurasburg will be positioned as a central lead facility in the global production footprint. The Group is therefore exploiting the plant's extensive digitalization and automation potential.

The production site in Eurasburg is facing substantial changes: the company will transform the building structures that have expanded piecemeal over time along with the fragmented logistics across different buildings and floors. In building 86 in particular, processes in the incoming goods, outgoing goods and central warehousing divisions will be optimized. A “brownfield-solution” has been adopted to modernize existing buildings.

|

“The implementation of the AutoStore solution marks a crucial step in modernizing our logistics processes and fully exploiting our future growth potential,” says Walter Fischer, Operations Director at EagleBurgmann. |

High-density storage for optimized logistics processes

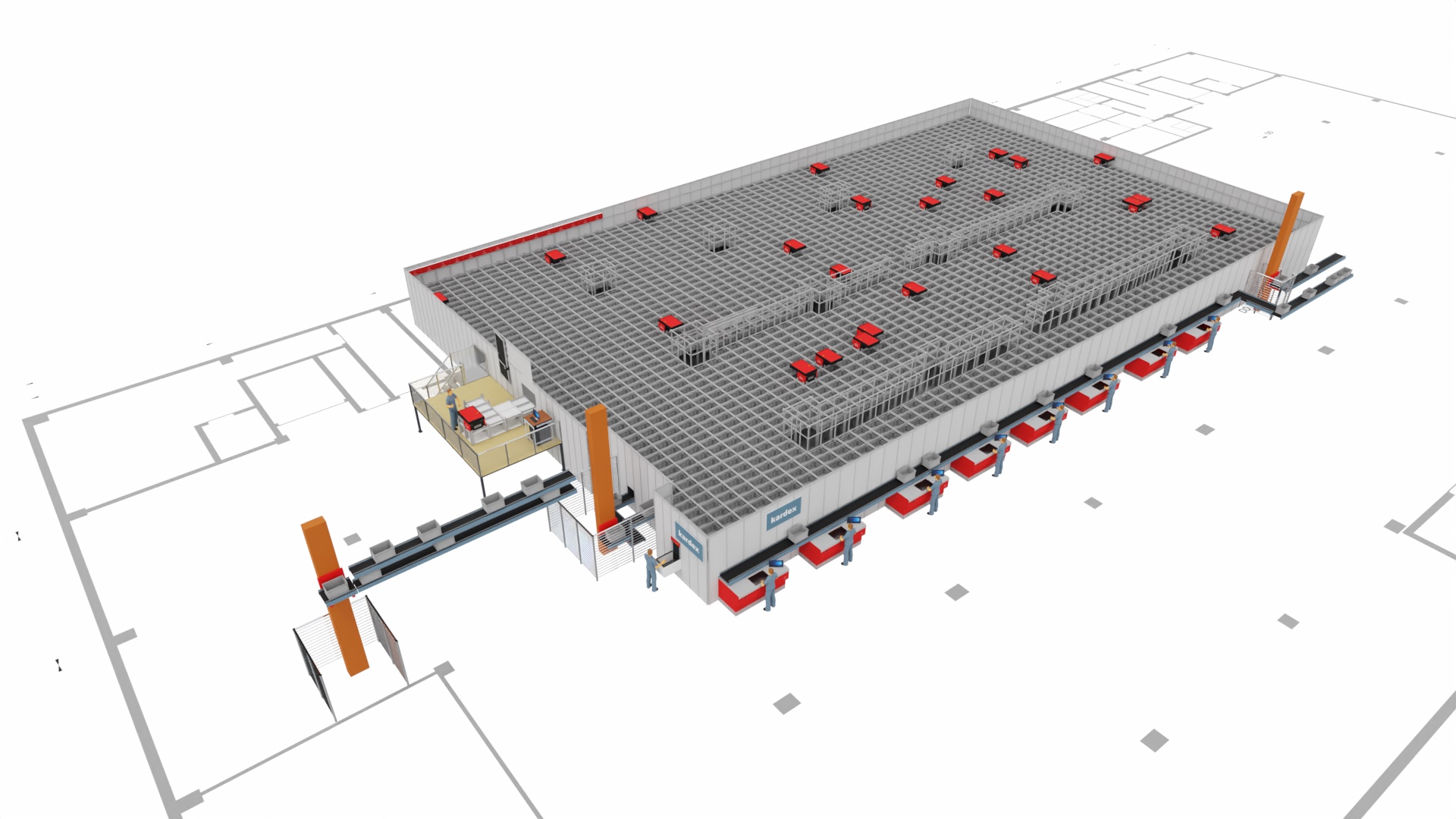

The aim of implementing the new automated warehouse is to centralize logistics with maximum density and storage capacity. The consolidation of small, decentralized storage areas at the site will create valuable production space. The new AutoStore solution creates space for approx. 19,800 bins and is operated by 24 state-of-the-art Red Line (R5) robots. The AutoStore will store raw parts, semi-finished parts to supply production and spare parts, which will significantly increase workflow efficiency.

The project in Eurasburg not only includes the AutoStore system; the project also includes the conversion and integration of the existing conveyor system into a new control concept. Kardex can also provide an annual service contract to guarantee maximum availability and long-term support throughout the entire life cycle of the system.

The 'Kardex style' is a perfect fit for EagleBurgmann

|

|

Falko Menz, Operations Manager at EagleBurgmann, adds “I’m looking forward to the launch of the AutoStore system, and my logistics team being able to work with the Kardex AutoStore team.” |

About Kardex