Pick and Place Robotic Solutions

Pick and place robotic solutions enable warehouses to efficiently manage growing inventories, process more orders, and meet shorter delivery deadlines.

By investing in cutting-edge automation technology, companies can unlock the full potential of their intralogistics systems to improve operational efficiency and maintain a competitive edge in the marketplace.

Pick and place robots meet the increasing demands of modern manufacturing and order fulfilment with precision and speed. These systems fully automate critical tasks such as order picking, palletising and depalletising, putaway, and replenishment.

Whether handling single items, cartons, or entire totes, pick and place robots streamline operations, reduce errors, and increase productivity.

Features & Benefits

-

Accurate Picking

Accelerate order picking with high-speed robotic systems that ensure quick and precise item handling

-

Efficient (De-)Palletising

Handle both single items and cartons, improve ergonomics and efficiency, and reduce manual labour

-

Fast Replenishment

Automate inventory replenishment to ensure products are always available when needed

-

High Availability

Maximise uptime with reliable, 24/7 robotic operations that keep your warehouse running efficiently

-

Less Costs

Reduce labor and operating costs by automating repetitive tasks and improving overall efficiency

-

Improved Ergonomics

Reduce strain and improve ergonomics at workstations with robotics handling repetitive tasks

Accurate Picking

Accelerate order picking with high-speed robotic systems that ensure quick and precise item handling

Efficient (De-)Palletising

Handle both single items and cartons, improve ergonomics and efficiency, and reduce manual labour

Fast Replenishment

Automate inventory replenishment to ensure products are always available when needed

High Availability

Maximise uptime with reliable, 24/7 robotic operations that keep your warehouse running efficiently

Less Costs

Reduce labor and operating costs by automating repetitive tasks and improving overall efficiency

Improved Ergonomics

Reduce strain and improve ergonomics at workstations with robotics handling repetitive tasks

Insights

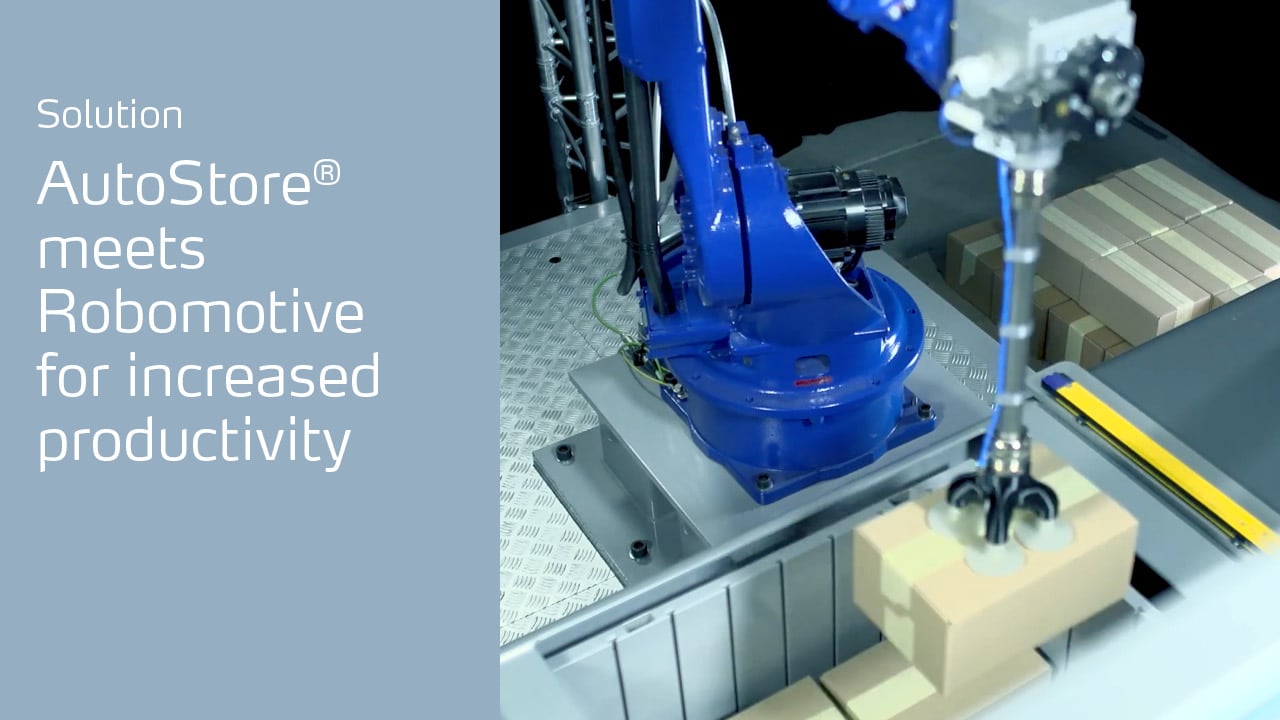

How can Pick and Place Robotics Integrate with AutoStore Solutions?

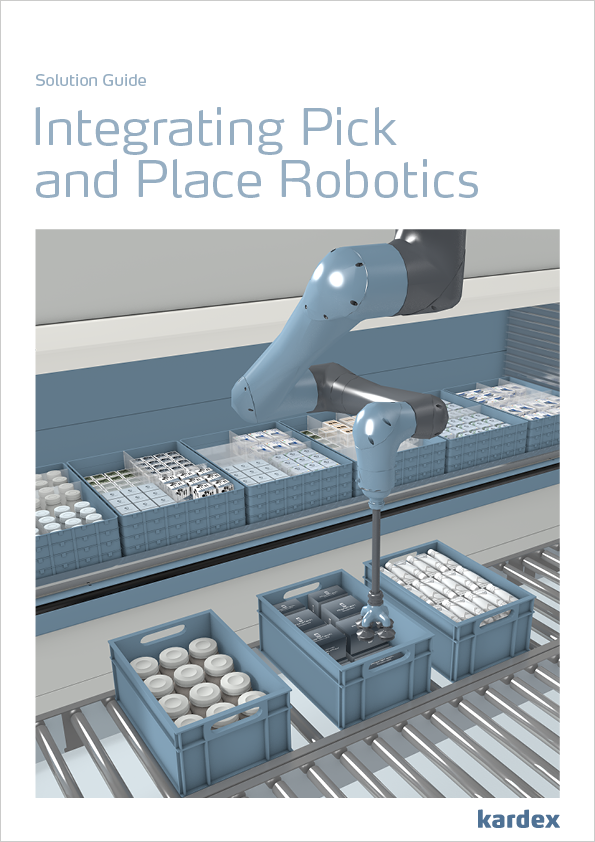

Fully Integrated Pick and Place Robotic Solutions

Kardex offers fully integrated pick and place robotic solutions designed to streamline warehouse operations. From design and implementation to service, Kardex is a single source for all critical components throughout the entire life cycle.

Robot Selection

The ideal pick and place robot for your warehouse depends on factors such as payload capacity, reach, and gripper type. Choose from

- Floor-bound

- Mobile on a floor rail

- Mobile hanging on a gantry/portal

Seamless Integration

All components of Kardex robotic solutions work together seamlessly for optimal performance and availability. Kardex ensures smooth integration into existing order fulfilment processes and material flows, increasing the efficiency of your operations.

Pick and place robots are versatile and can perform a variety of logistics tasks, such as

- (De-)palletising: Automated depalletising after the incoming goods area is one of the most established applications using pick and place robotics. Robots can pick items or cartons and place them in standard bins. Palletising is often a very critical work step from an ergonomic point of view and frequently associated with only moderate efficiency. Pick and place robotics can change that. Many warehouses have fully automated this process step by using robotics to palletise after packaging. The robots can either palletise on a pallet, roll cage trolley or a container (which is common in e-commerce).

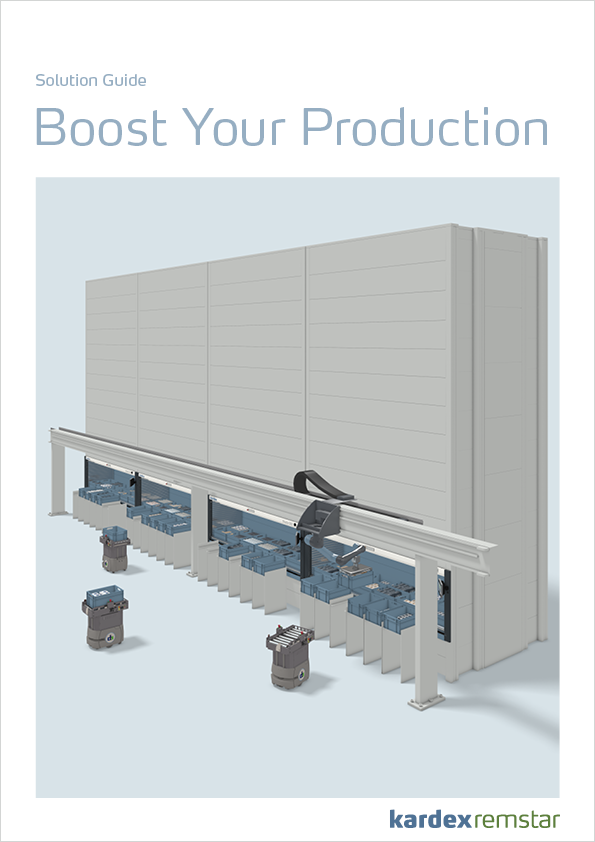

- Replenishment/storage: Easy to combine with the depalletising process, pick and place robotics can be used to complete the replenishing task. They can automatically pick articles from pallets and store them in an automated storage system (e.g. AutoStore or Vertical Lift Module). This means one single process step for both depalletising and replenishment.

- Fully automated order picking: Pick and place robotics are also used for order picking. The robots pick individual parts from a storage system and place them in a bin or on a conveyor for efficient and fully automated order picking. Integrating pick and place robotics into an order picking process provides a fully automated flexible and scalable solution that can be easily adapted as business requirements grow or change.

More Solutions from Kardex

Intuitive Picking Assistant

The Intuitive Picking Assistant elevates picking processes of AutoStore™ solutions to the next level. By projecting all relevant picking information it guides the operator through the picking process.

Wearable Task Assistant

The Wearable Task Assistant enhances the efficiency of your picking process by guiding the operator through each task. This portable device makes the picking process even more efficient. Featuring a hands-free scanner, pick-and-place support and a colour-coded wrist display, it reduces errors and enhances the overall quality of the picking operation.