Range and Components Improve order fulfillment and unlock real-time customization

Application range

The automated warehouse picking system AutoStore is suitable for companies of all sizes and industries that are storing and handling small parts. Below is an overview of some typical applications.

From same day delivery demands to customized products and stress-free returns, many companies struggle to keep up with today’s customer expectations in eCommerce order fulfillment. With this in mind, tailor-made AutoStore solutions from Kardex offer several features to help eCommerce providers successfully grow while maintaining a competitive edge.

As customer requirements continue to change at a minute’s notice, companies need to keep a steady growing range of parts in stock. The warehouse automation solution AutoStore supplies just-in-time production lines with parts that are stored in the densest possible way.

Whether it`s the backroom of a store, the center of a store or a small corner of a warehouse – providing high density storage, the automated warehouse system AutoStore is compact enough to fit almost anywhere. The innovative warehouse solution enables you to expand your in-store product assortment, while creating an engaging customer experience.

AutoStore components

Tab Navigation

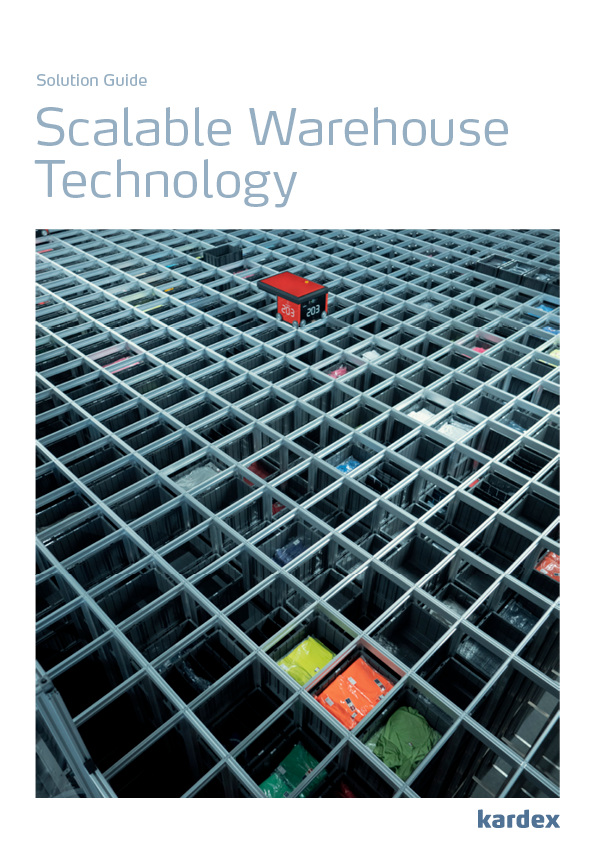

Grid

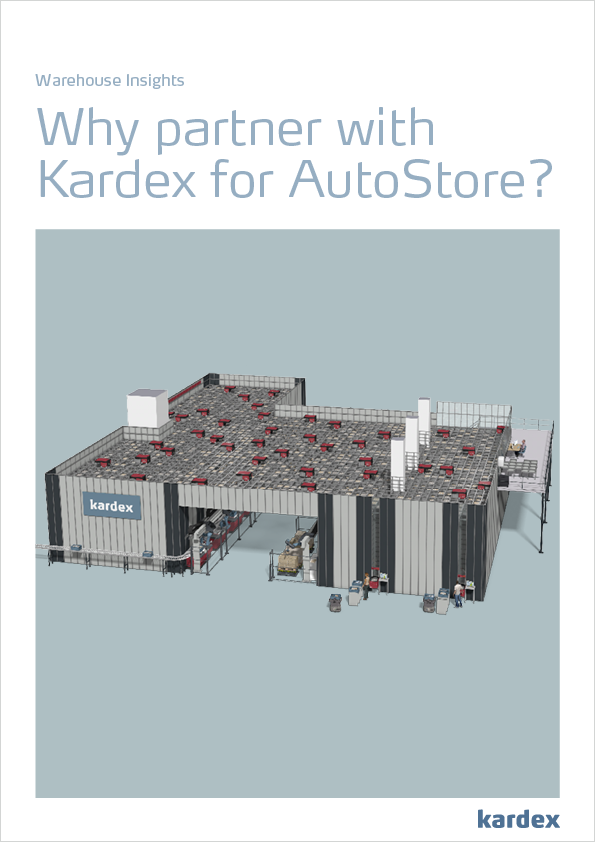

The modular aluminum grid is lightweight and flexible. It holds the bins stacked neatly on top of each other while providing tracks in X and Y direction for the AutoStore robots to drive on, enabling them to access any storage location within the grid. The flexible, tailor-made system fits even the most unusually shaped facilities, allowing the AutoStore grid to be placed around columns, on mezzanines and across multiple levels - to maximize your existing warehouse space. Grid expansions are possible at any time without interrupting daily operations.

Bins

The high density storage solution AutoStore is ideal for warehouses operating a high number of SKUs – an average system holds 34,000 bins. Durable, specialized, and stackable small parts storage bins hold inventory and the weight of multiple bins stacked one above another. Standard AutoStore bins are molded from high-grade polyethylene (HDPE). Users may also equip the system with special ESD bins to protect sensitive components from electrostatic discharge. Each bin can hold a single SKU or be subdivided into up to 32 storage locations. Even standard KLT boxes (Euro containers) can be stored within AutoStore bins. At any given moment, the software has complete control over the content of each storage bin.

The following three AutoStore bin sizes are available:

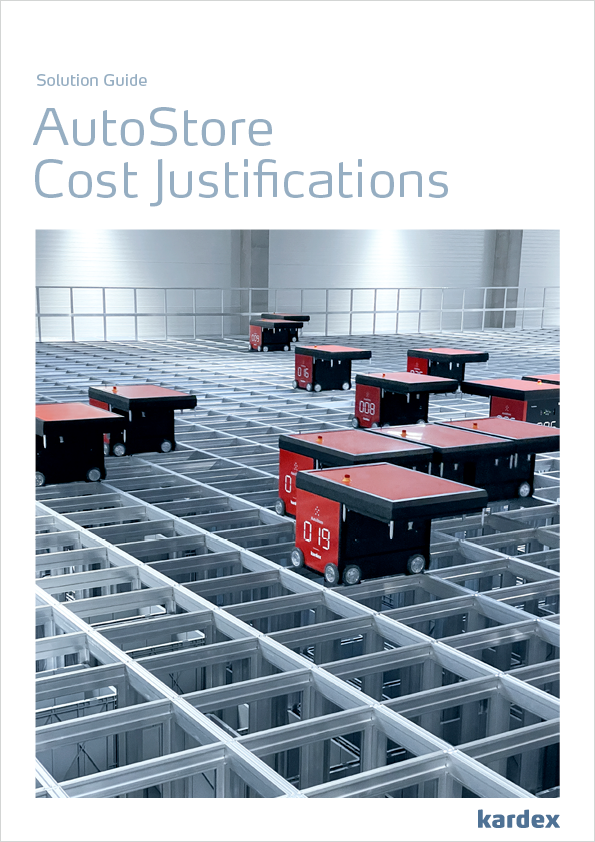

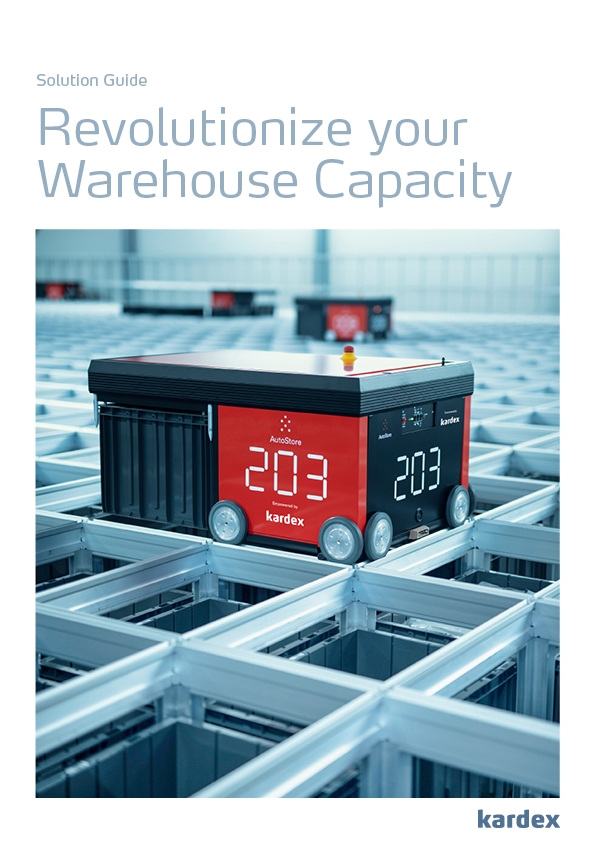

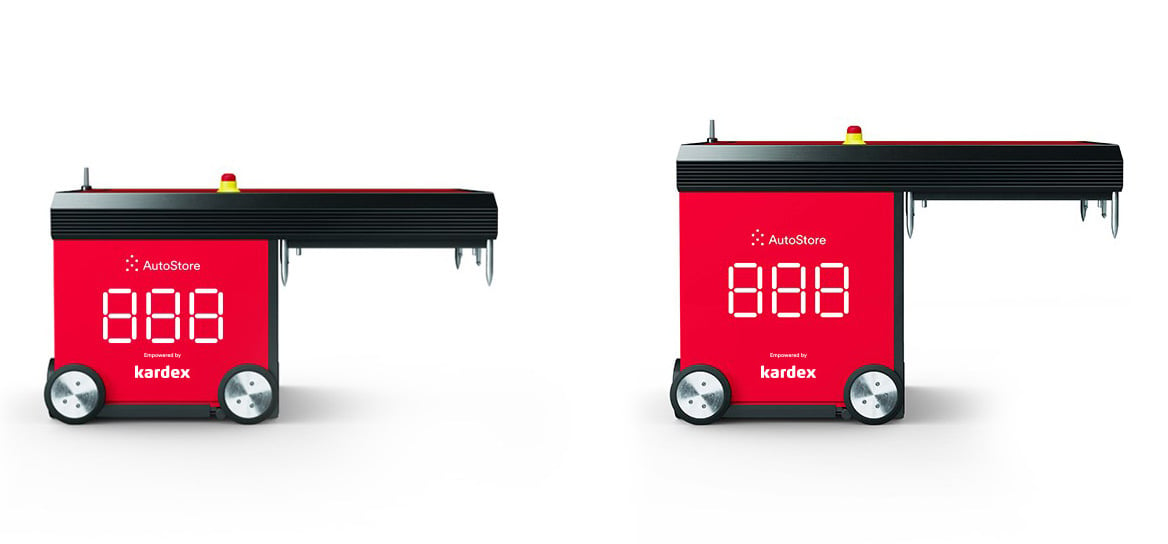

Robots

High-speed AutoStore robots drive along the top of the grid, continuously picking up bins, rearranging them and presenting them at the respective workstations, where a variety of warehouse operations can be performed (picking, replenishment, inventory control, etc.). They can operate around the clock – even in total darkness and at low temperatures. AutoStore robots are highly efficient – the energy consumed by 10 robots is equal to a single conventional vacuum cleaner. All robots are connected to each other wirelessly and communicate via WLAN with the controller, which calculates the shortest available transport routes. AutoStore robots self-diagnose on a preventive basis and automatically move to the maintenance zone when required. If one robot breaks down, no problem – another one takes over its tasks.

The award-winning AutoStore Red Line consists of two robot types – the R5 and the R5+. While the AutoStore R5 robot is compatible with bin heights of 220 and 330 mm, the AutoStore R5+ robot can also handle the tallest bins at 425 mm in height. With their energy-efficient motors and a recovery system, Red Line AutoStore robots are tirelessly in action. When battery charge gets low or there are no tasks to be completed, they dock themselves independently to one of the charging stations located at the edge of the grid.

Ports

AutoStore ports, or workstations, are where bins are presented for picking, replenishing and other inventory actions. AutoStore ports can be further enhanced with pick-to-light technology, which is especially helpful when bins are sub-divided for multiple SKUs. A software driven laser pointer will guide the operator to the exact pick location to increase pick accuracy and speed.

A wide range of ports offering various functions and speeds are available.

Conveyor Port

This workstation is designed to be simple, sleek and functional. The AutoStore bins are placed on a conveyor belt and transported to the operator through an opening outside the grid. The maximum throughput for the AutoStore Conveyor Port is 240 bins/hour on an elevated level and 180 bins/hour on the floor level.

Carousel Port

Enhancing picking performance, the AutoStore Carousel port operates with three rotating arms, each holding a bin. One bin tray is located in the operator's access area and the other two in the robot's access area, enabling faster bin presentation without interruptions. The maximum throughput is 350 bins/hour.

Swing Port

The AutoStore Swing Port is a workstation designed for picking and putaway from above or below the grid. The performance depends on the lift height, e.g., 160 bins/hour with an 8 meters (26.2 feet) bin lift.

Relay Port

The AutoStore Relay Port is a workstation that consists of a picking module and 3 to 6 buffer modules. AutoStore robots can deliver bins to the port at any time and transport bins already approved by the operator back into the grid. The advantage: No robot has to wait, and the articles can be sequenced according to the order. With 6 buffer modules, this port can achieve a throughput of up to 650 bins/hour.

Controller

The AutoStore controller keeps track of everything and is responsible for storage location management. It is the command center, traffic control unit and database holder for the entire AutoStore system. Since AutoStore is a closed system, the controller represents the connection between AutoStore and the Warehouse Management Software (WMS). AutoStore systems can be seamlessly connected to any ERP/WMS.

Complementary technology

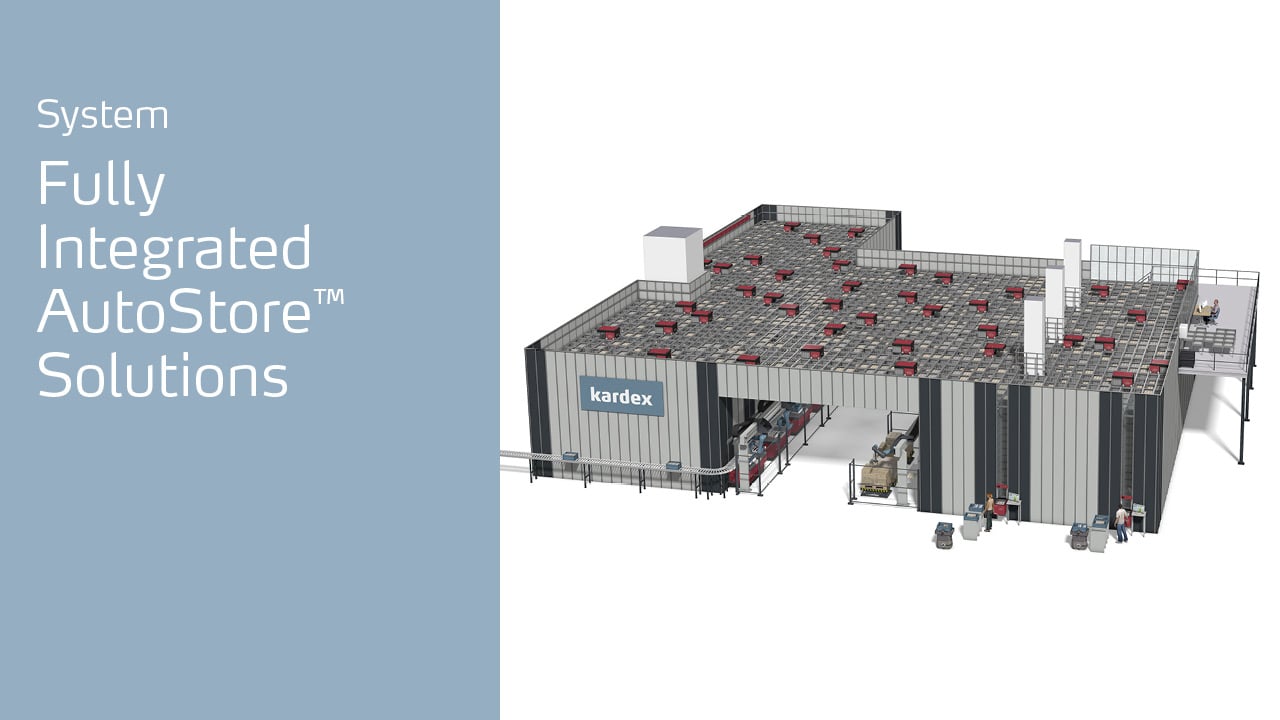

Kardex can install the small parts storage solution AutoStore either as a stand-alone system or integrated into an overall logistics concept, including additional warehouse automation technology. By pushing warehouse automation to its limits, order fulfillment will see significant cost savings and enhanced performance.

AutoStore ports can easily be connected to automated conveyor systems. This enables a smooth transition to sub-systems such as automatic carton erectors, carton sealing machines, labelling machines, palletizers, AGVs (Automated Guided Vehicles) and AMRs (Autonomous Mobile Robots).

Kardex offers modular IT concepts individually adapted to our customer’s intralogistics processes and warehouse requirements. These integrate into existing process environments or serve as superior control software. Kardex Mlog’s modular software solution Kardex Control Center manages material flow and warehouse management processes fast and efficiently.

AutoStore ports can also be operated fully automatically by integrated high speed pick and place robots. These are capable of running various AutoStore processes including pick to tote, pick to belt, pick to pallet, consolidation and replenishment. Using a unique, internally developed 3D vision software, the robots can precisely pick, process and place single items, carton boxes or full cases to and from any picking station. With a gantry solution, one pick and place robot can even operate several AutoStore ports at the same time, 24 hours a day at high speed. Taking the performance of AutoStore systems to the next level, pick and place robots contribute to an even higher profitability of the investment in warehouse automation.

.jpeg)

.png)

-1.png)

-1.png)

-1.jpg)